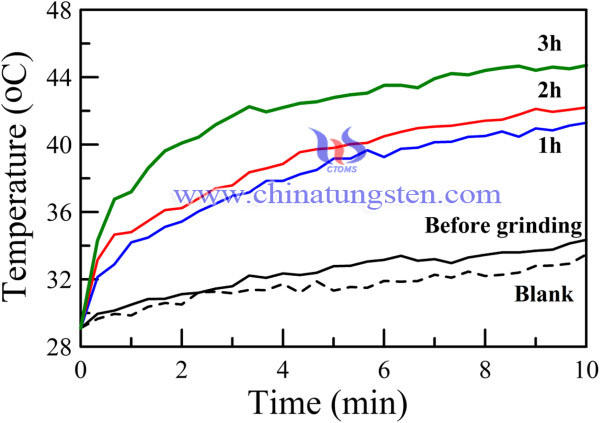

Near-Infrared Photothermal Conversion Property of Cs0.33WO3 Nanoparticles

- Details

- Category: Tungsten Information

- Published on Friday, 19 July 2019 14:31

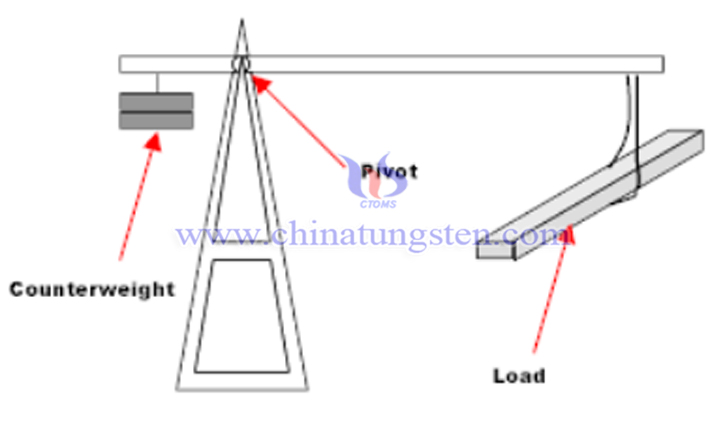

Tungsten Alloy Counterweight in Golf Club Head

- Details

- Category: Tungsten Information

- Published on Friday, 19 July 2019 14:22

Tungsten alloy counterweight has been used for weighting golf club head in order to gain better performance. The present club provides a golf club head with performance weighting through the use of a sole component composed of a tungsten alloy material.

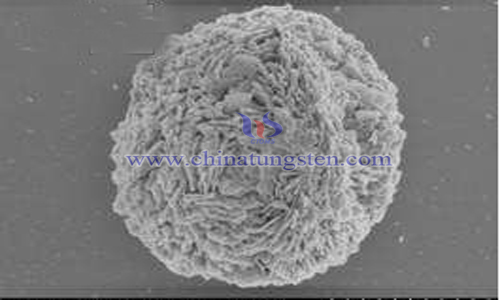

Preparation Method of Spherical Barium Tungstate

- Details

- Category: Tungsten Information

- Published on Friday, 19 July 2019 01:32

Tungstate nanomaterial has a good application prospects in scintillation materials, optical fibers, photoluminescent materials, microwave applications, humidity sensors, magnetic devices, catalysts and corrosion inhibitors, and have become a hot research topic in recent years. In addition to the above-mentioned application potential, barium tungstate nanomaterial is also a good photocatalyst for the degradation of organic pollutants under light irradiation.

Metallographic Preparation of Plasma Sprayed Tungsten Carbide Coating

- Details

- Category: Tungsten Information

- Published on Thursday, 18 July 2019 22:57

Tungsten carbide coating by plasma spraying is mainly used for anti-sliding friction, vibration friction, wear resistance and corrosion protection of aero-engines below 500 ℃. It has been widely used in aero-engines at home and abroad.

Molybdenum Silicate Coating for Niobium Tungsten Alloy Combustor of Engine

- Details

- Category: Tungsten Information

- Published on Thursday, 18 July 2019 22:45

Bipropellant attitude and orbit control engine is an important part of modern space vehicles and strategic and tactical weapons, which is widely used in orbit control and attitude adjustment. In recent years, with the development of new aircraft or weapons, the requirement for engine performance has been increasing. It requires that specific impulse be increased and chamber pressure be increased, so as to reduce propellant consumption and engine weight, prolong engine life or increase the range of strategic weapons.

Cesium Tungsten Bronze Nanoparticles by Flame-assisted Spray Pyrolysis

- Details

- Category: Tungsten Information

- Published on Thursday, 18 July 2019 18:12

Highly crystalline and hexagonal single-phase cesium tungsten bronze(Cs0.32WO3) nanoparticles can be successfully synthesized by a flame-assisted spray pyrolysis. The proposed process has several advantages, including a short reaction time and the ability to yield products with high purity and good energy efficiency. Furthermore, the Cs0.32WO3 nanoparticles produced in this research showed a remarkable near-infrared shielding ability with a 97.7% cut-off at 1500 nm.

Tungsten Alloy Counterweight in Crane

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 17:41

Every crane has a set of tungsten alloy counterweight which guarantees the counterbalance and prevents the machine of toppling over. Mobile cranes are heavy equipment vehicles that have been designed to lift, lower and transport heavy loads. They are employed in the off-highway industry to move freights beyond the normal capability of a man.

Why It is Important to Apply Proper Counter Weight?

The tungsten alloy counterweight plays a critical role. If it is not designed properly and doesn’t possess the right size and shape, it turns automatically into an extremely dangerous subject that can make the vehicle topple over in the direction of the load or backward. When trying to lift a load, a crane can topple over in the load’s direction if the counterweight set up is too light for the load and booms the configuration. Otherwise, the counterweight can topple a crane backwards in situations when:

The counterweight is too heavy for the boom configuration.

The crane is traveling up a slope.

When the crane is on soft ground, inadequate timbers are placed under the outrigger pads below the counterweight.

Outriggers or any other ground support are not extended or lowered into position and cannot resist the combined weights and tipping forces.

If the boom configuration is lifted too high and there is not enough load applied on it.

Tungsten Alloy Counterweight are The Safest Option

Mobile cranes are far smaller than the fixed crane configurations, but still facing the same loads challenges. Especially because of their size, they need small, but very heavy counterweights. Thanks to its density only tungsten alloy can meet those requirements. Safe and risk reduction safety guidelines should be followed on a daily basis to ensure that the vehicle is in proper working condition. Preventive maintenance and safety inspections should be regularly performed to detect potential accidents. Mobile crane counterweights ensure the safe operation of the vehicle by keeping it stable and upright. Best design practices, most reliable raw material selection as tungsten and regular safety inspections are essential for the performance of a high-quality counterweight.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten Alloy Counterweight in Helicopter

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 17:34

Tungsten alloy counterweight is used in a wide range of different applications, including helicopter. Here, in this article, we take a closer look at two cases of its application in different helicopters.

Tungsten Alloy Crankshaft Counterweights in Motorbike

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 17:27

Tungsten alloy is an excellent material to manufacture tungsten alloy crankshaft counterweights in motorbike. All engines need perfectly balanced crankshafts to ensure optimized performance. If a crankshaft is not correctly balanced, the consequences can be severe.

The Application of Tungsten Alloy Counterweight in Trucks

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 17:15

Counterweight is an integral part of a variety of big machines dealing with huge load. By balancing the weight, it secures a safety performance of tractors, trucks, cranes, excavators and others. If you own a truck that you want to have a safe trip, it is important that you do not just go out into the wild with the equipment that came with your vehicle. Even Jeeps usually require special upgrades to ensure that they are able to handle driving on terrain that is not paved. Failing to ensure that you have the right elevation and counterweight in your truck, tires or wheels can lead to expensive damage. Tungsten alloy counterweight is the best choice in truck to ensure the balance of weight when loading and unloading goods.

sales@chinatungsten.com

sales@chinatungsten.com