Tungsten Disulfide Modified Phenolic Resin

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 21:53

Phenolic resin refers to a polycondensate synthesized by phenols and aldehydes under the action of an acidic or basic catalyst, which has excellent adhesion, excellent heat resistance, unique ablation resistance and good flame retardancy. Widely used in aircraft and aviation, military equipment, automotive and transportation, construction and other aspects.

Tungsten Trioxide Carbon Nanotube Composite Films

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 21:48

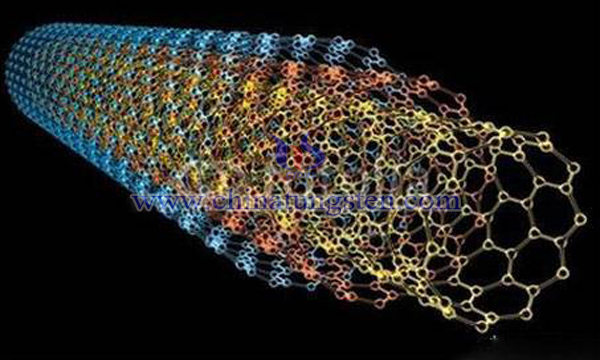

The structure of carbon nanotubes is particularly a tube composed of a hexagonal network similar to graphite. The unique nano-hollow structure and closed helical structure with different topological configurations make it have a lot of special excellent properties. Such as good electrical conductivity, heat resistance, high mechanical strength, corrosion resistance, self-lubricating and biocompatibility, etc.

Vanadium Tungsten Titanium SCR Flue Gas Denitrification Catalyst Preparation from Titanium-Containing Blast Furnace Slag

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 21:40

A large amount of blast furnace slag will be discharged in the process of blast furnace ironmaking. If not properly treated, it will occupy land, pollute the environment and cause waste of resources. Blast furnace slag contains valuable metals such as titanium, silicon, aluminium and calcium. It can be separated, extracted and processed into chemical products by appropriate methods. It can make rational use of industrial waste resources and solve environmental pollution problems.

Recycling of Tungsten Trioxide in Waste Flue Gas Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 13:38

SCR denitration technology is a necessary means for power plants to achieve ultra-clean emissions. Catalysts, as a core part of SCR denitration technology, lose their activity due to wear or blockage during operation. Some of the regenerable catalysts can be reused after regeneration, while the catalysts that cannot be regenerated face the situation of rational utilization and disposal.

Preparation Method of Ruthenium-tungsten Composite Oxide Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 29 July 2019 13:15

Nitrogen oxides (NOx) are important atmospheric pollutants that can cause environmental problems such as acid rain and photochemical smog, as well as direct damage to the human respiratory system. In addition, it also has an important contribution to the increasingly serious ash pollution in our country. Therefore, effective control of NOx emissions is a major strategic need in China.

Manufacture of High Temperature Resistant Tungsten Heater

- Details

- Category: Tungsten Information

- Published on Sunday, 28 July 2019 22:21

Tungsten is China's advantageous resource. China's reserves and consumption rank first in the world. However, the high value-added high-end products of tungsten products are monopolized by foreign companies, especially tungsten heating elements and supports used in high temperature environments. Mainly relying on imports, domestic imitation products are poor in thermal stability, easy to deform, short in life and limited in application.

Graphene-bismuth Tungstate Lamellar Nano Photocatalytic Materials

- Details

- Category: Tungsten Information

- Published on Sunday, 28 July 2019 22:13

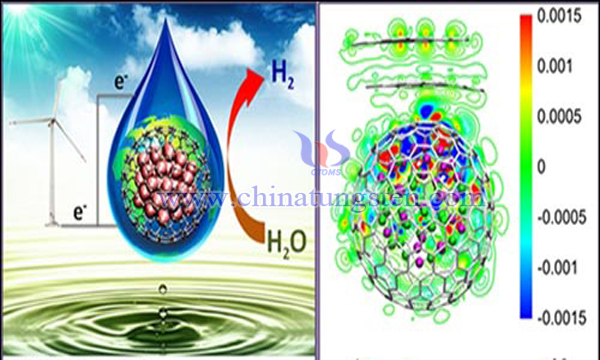

Bismuth tungstate (Bi2WO6) is a typical n-type semiconductor formed from octahedral WO6 and Bi2O2 layers. Bi2WO6 has excellent chemical properties, unique ferroelectric properties, catalytic properties and magnetic susceptibility of non-linear dielectrics. Bi2WO6 is a good visible-light photocatalyst material.

Tungsten-copper Thin Films Deposited by Ion Beam Sputtering

- Details

- Category: Tungsten Information

- Published on Sunday, 28 July 2019 22:06

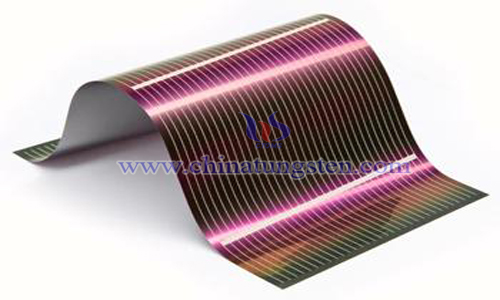

Tungsten-copper composite is one of the heat sink materials widely used in power devices. It has good thermal conductivity and thermal expansion coefficient close to that of Si, GaAs and other semiconductor cores. Density of composites is the main factor affecting the electrical conductivity, thermal conductivity and expansion properties of composites, and it is also the key technical index.

Nano Tungsten Trioxide Preparation by Sol-Gel Method

- Details

- Category: Tungsten Information

- Published on Sunday, 28 July 2019 22:02

Nano tungsten trioxide powder is an important industrial raw material, which can be used to prepare nano-tungsten powder and nano-tungsten carbide powder. In addition, nano WO3 has a strong ability to absorb electromagnetic waves. It can be used as a good absorbent material in the utilization of solar energy and an important invisible material in the military.

Ceramic Bricks Preparation from Tungsten Tailings

- Details

- Category: Tungsten Information

- Published on Sunday, 28 July 2019 21:55

Tungsten tailings are solid waste discharged from tungsten-bearing minerals in tungsten ores. China's tungsten resources have very low taste and few rich ores, and only 20% of the tungsten grade (WO3) is greater than 0.5%. As a result, a large number of tungsten tailings are produced in the process of beneficiation.

sales@chinatungsten.com

sales@chinatungsten.com