Nano Tungsten Oxide Preparation by Carbon Nanotubes Template

- Details

- Category: Tungsten Information

- Published on Saturday, 15 September 2018 23:30

Nanomaterials refer to materials (1-100 nm) with at least one dimension within the nanoscale in three-dimensional space. According to the classification of space dimension, nanomaterials can be divided into zero dimension, one-dimensional, two-dimensional and so on. Zero dimensional tungsten oxide mainly refers to nano tungsten oxide powders.

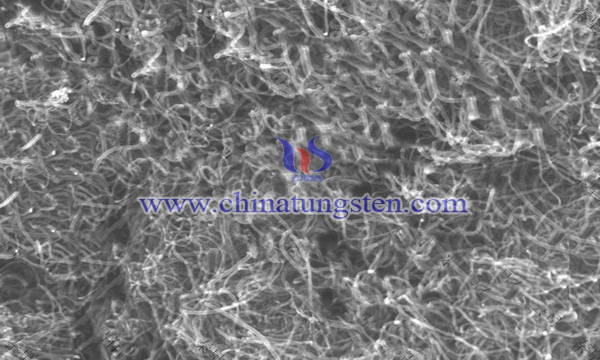

Carbon nanotubes (CNTs) are the most commonly used template materials. They have been successfully used in the preparation of nanorods such as GeO2, V2O5, WO3 and MoO3. In recent studies, some scholars have used CNTs as templates and morphology modifiers to control the amount of tungstic acid deposited on the surface of CNTs and the calcination temperature so as to control the tungstic acid content in carbon. The surface coverage of the nanotubes and the growth of tungsten oxide can lead to the formation of nano-tungsten oxide with different morphologies and sizes, such as sheet, granular and rod.

1.Carbon nanotubes (CNTs) with 15 mg diameter of 10 nm and 3 layers were immersed in hydrochloric acid and stirred at 140 ℃ for reflux, filtration, drying, and then dispersed in 150 mL ethylene glycol by ultrasonic wave for 15 h to obtain uniform CNTs suspension.

2.Sodium tungstate was completely dissolved in the mixture of deionized water and ethylene glycol, and 0.05 mol/L sodium tungstate solution was obtained. The molar ratio of sodium tungstate to carbon nanotubes was 2:1.

3.The carbon nanotube ethylene glycol suspension in step (1) is added to the sodium tungstate solution in step (2) and stirred with a constant temperature magnetic stirrer in the oil bath. The mixture is uniform. A suitable amount of hydrochloric acid solution is dripped into the system by a micro-injector at 60 ℃ in the oil bath with a hydrochloric acid concentration of 6 mol/L. When the dosage is 4 mL, the pH value of the adjusting system is 3.

4.Increase the reaction temperature to 100 ℃, reaction time to 3h, then generate tungstic acid, vacuum filter, washing, vacuum drying temperature and time are 100 C and 1 h, get carbon nanotubes / tungstic acid composite; spread the composite in the corundum reaction boat, together with the corundum reaction boat in the tubular resistance furnace stone The carbon nanotubes/tungsten oxide were obtained by heating the samples at 500 C and 0.5 h respectively in the high temperature reaction zone. The carbon nanotubes/tungsten oxide was taken out at normal temperature. The shape of the tungsten oxide was quadrangular and the size of the tungsten oxide was larger than 1000 nm.

Carbon nanotubes (CNTs) are used as templates and morphology modifiers to nucleate and grow tungstic acid directly on the surface of CNTs to form CNTs/tungstic acid composites. The composites are then placed in the high temperature reaction zone of a tubular furnace, and inert atmosphere is introduced. In the process of dehydration of tungstic acid and conversion to tungsten oxide, CNTs are retained and carbon is utilized. The toughness of nanotube bundles supports tungsten oxide so that tungsten oxide inherits the morphology of tungstic acid. The raw materials used in this process are easy to obtain, the preparation process is simple, the parameters are simple to control, and the morphology and size of the tungsten oxide obtained can be controlled. It has a wide application prospect.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com