Nano Tungsten Carbide Fibers Recovery from Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:54

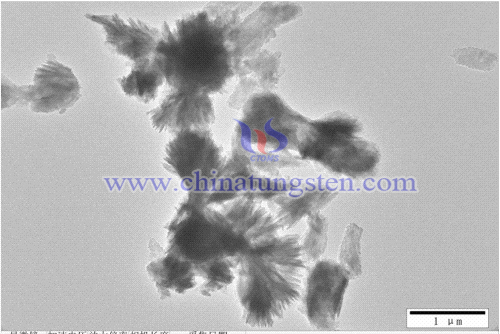

Tungsten carbide (WC) is a black hexagonal crystal with metallic luster and similar hardness to diamond. Since Levy R B first pointed out that tungsten carbide has platinum-like (Pt) catalytic effect in 1973, researchers began to try to use tungsten carbide instead of noble metal catalysts in heterogeneous catalysis and electrocatalysis.

Advanced Nano Tungsten Powder Manufacturing Scheme

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:45

China is a large tungsten-producing country, with more than 20,000 tons of crude tungsten products exported every year. 50% of the tungsten used by the world's major industrial countries is supplied by China. The output of pure tungsten metal products in China is about 1,000-1,200 tons, and the output is also in the forefront of the world. However, in terms of production technology and intellectual property rights of high-quality tungsten materials, China's quantity is rare.

All-purpose Tungsten Carbide Thermal Spraying Material Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:37

Thermal spray welding (coating) of cemented carbide powder is a technology for hardening and strengthening mechanical surface developed since 1950s. This technology may effectively prolong the service life of machinery. Tungsten carbide is the most common raw material for thermal spray welding (coating).

Ammonium Paratungstate Low Cost Treatment from Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:31

The composition of tungsten waste is complex, difficult to extract and complicated to remove. This kind of APT is manufactured by traditional method with long technological process, narrow adaptability of raw materials, large investment in equipment, unstable products and poor economic benefits. In recent years, the preparation of ammonium paratungstate from tungsten waste has been explored and some results have been achieved.

Ferro-tungsten Recovery from Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:17

Ferro-tungsten is an important raw material in industry. Ferro-tungsten is widely used in mining, metallurgy, machinery, construction, transportation, electronics, aerospace and military industries. Traditional ferro-tungsten is made from wolframite concentrate, mixed with additives in a certain proportion and smelted in electric furnace. This smelting process has some technical problems, such as difficult source of raw materials, high requirement for raw materials, high cost, and crushing by crusher in the preparation process, resulting in uneven products.

Tungsten Oxide Nanowires As Microwave Absorbing Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:10

Tungsten oxide has unique physical properties such as photochromism, electrochromism, thermochromism and gas sensitivity. Its color change can be achieved by changing irradiation wavelength, temperature or applied voltage. Therefore, tungsten oxide can be used in many fields such as sensors, electronic devices and so on. The nature of Yue Yue, its development and research has become a hotspot all over the world.

Tungsten Oxide Nanowires Preparation by Hydrothermal Synthesis Method

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 21:01

Tungsten oxide nanowires are a fantastic one-dimensional material, which is rarely introduced on academic websites. It may not be known to many that tungsten oxide nanowires can also be used as absorbing materials for radar electromagnetic waves, such as stealth fighter coatings, strategic missile concealment and so on.

Batch Preparation of Tungsten Disulfide Quantum Dots

- Details

- Category: Tungsten Information

- Published on Sunday, 04 August 2019 21:27

Quantum dots are zero-dimensional nanomaterials consisting of a small number of atoms. In recent years, quantum dots (QDs), as a new type of nanomaterials with unique physical properties, have attracted extensive interest of researchers at home and abroad. Their research contents involve physics, chemistry, materials and other disciplines, and have become a new interdisciplinary subject.

Tungsten Disulfide-Activated Carbon Composites

- Details

- Category: Tungsten Information

- Published on Sunday, 04 August 2019 21:22

In the field of energy, supercapacitor is a new type of energy storage device with rapid development in recent years. Its performance is between traditional capacitor and secondary battery. It has the characteristics of high power, fast charging and discharging rate, long cycle life, wide operating temperature range, good safety performance and economic and environmental protection. They are widely used.

Cobalt Tungstate Nano Materials with Cockscomb Flower

- Details

- Category: Tungsten Information

- Published on Sunday, 04 August 2019 20:53

Supercapacitors are energy storage devices between batteries and traditional capacitors. Because of its high charging and discharging efficiency, high power density, long cycle life and friendly environment, it is widely used in transportation, mobile communications, information technology, aviation, aerospace and national defense science and technology.

sales@chinatungsten.com

sales@chinatungsten.com