Cadmium Selenide - Bismuth Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:50

Cadmium selenide nanocrystals are the most widely studied and promising class of II-VI semiconductor nanocrystals. They have attracted worldwide attention due to their important non-linear optical properties, luminescent properties and other physical and chemical properties.

Tungsten Alloy PCB Bit

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:45

The through hole is one of the important components of PCB. Its function is to fix or locate the electrical connection channels and devices between layers. Mechanical drilling with PCB micro-drill is the most commonly used processing method.

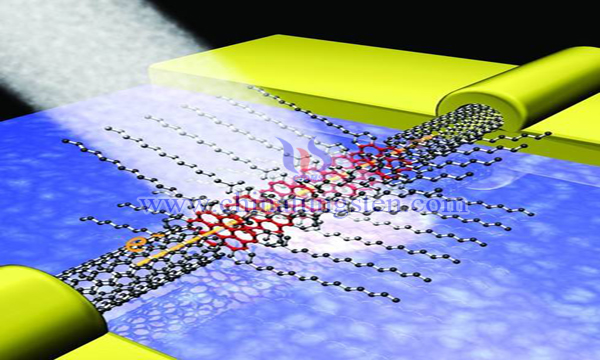

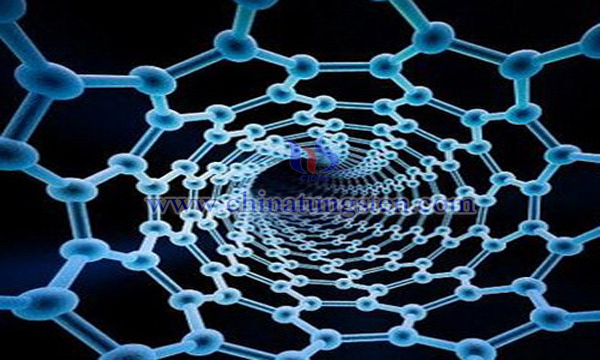

Metallic Tungsten Selenide Nanosheets - Carbon Nanotubes Hybrid Structure Electrocatalysts

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:38

Transition metal chalcogenides, as a new two-dimensional layered material, have similar properties to graphene and are widely used in field-effect transistors, sensors, energy storage and catalysis. Tungsten selenide, as an undeveloped transition metal chalcogenide, is a promising non-noble metal catalyst. Its performance is also influenced by the phase and electronic structure.

Tungsten Steel Functionally Gradient Materials

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:31

In the future, the refractory tungsten metal and structural material steel need to be joined together in the divertor part of fusion equipment. Due to the huge difference of thermal expansion coefficient between tungsten and steel, the joint of tungsten and steel obtained by conventional welding method has large residual stress and working pressure, which will lead to deformation and cracking.

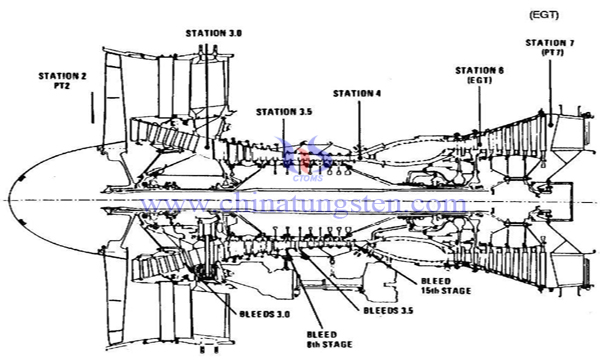

Rare Earth Tungsten High Specific Weight Alloy for Balance Shaft of Aircraft Engine

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:24

The balancing shaft of aircraft engine is a simple and practical engine part. It can effectively reduce the vibration of aircraft in flight, because when the engine is in working state, the piston moves very fast and the speed is very uneven. The balancing shaft can effectively improve the comfort of passengers. Tungsten-based high specific gravity alloys are commonly used in balancing axles of aircraft engines.

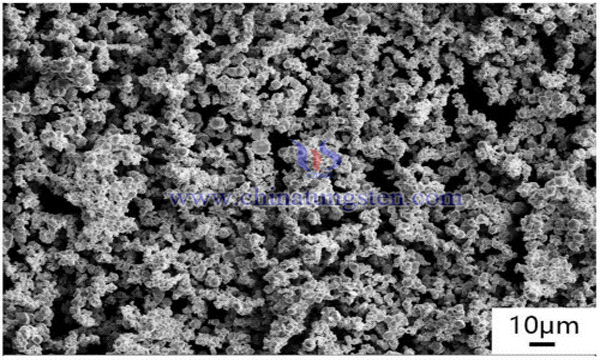

High Density Unbonded Phase Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 22:15

Cemented carbide is a kind of alloy material made by powder metallurgy process from hard compounds of refractory metals and bonded metals. Cemented carbide has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, so it is known as "industrial teeth".

Tungsten Carbide Inhibitor Composite Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 13:41

Ultra-fine grained tungsten carbide-based hard alloy has high strength and high hardness "double high" performance, which can be used in the production of printed circuit board micro drill bits, dot matrix printer printing needles, precision tooling, and difficult material tools.

Gold-doped Yttrium-substrated Tungsten Oxide Composite Gas Sensing Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 13:29

Tungsten oxynitride NOx gas is one of the culprits in destroying the ecological environment on which humans depend. According to medical data, short-term exposure to NOx gas may cause respiratory diseases, such as airway inflammation in healthy people, and aggravate the condition of people with asthma. If exposed to NOx for a long time, it may cause pulmonary edema and even death.

Green and Energy-saving Separation of Tungsten-Tin Ore

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 22:35

There has always been a low (poor) grade tungsten-tin associated ore in the tungsten-tin production industry, which is particularly common in Yunnan. Because the material and chemical properties of the two metal compounds are similar, the separation of the two metals in the industrial production process has always been a difficult problem that puzzles the industrial production technology. The traditional production method has been characterized by high pollution and high energy consumption, which makes it difficult to conform to the national industrial policy.

Ammonium Paratungstate Recovery from Soft Waste Containing Tungsten

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 August 2019 22:13

The tungsten-containing soft waste referred to in the recovery and treatment of tungsten wastes is a kind of soft waste such as leaching residue in the production process of ammonium metatungstate (AMT), ammonium paratungstate flooring material and yellow tungsten flooring material, air pipe material, ammonium paratungstate evaporation mother liquor produced in the production process of tungsten oxide. Inevitably, tungsten still exists in these tungsten-containing wastes. It can be recycled.

sales@chinatungsten.com

sales@chinatungsten.com