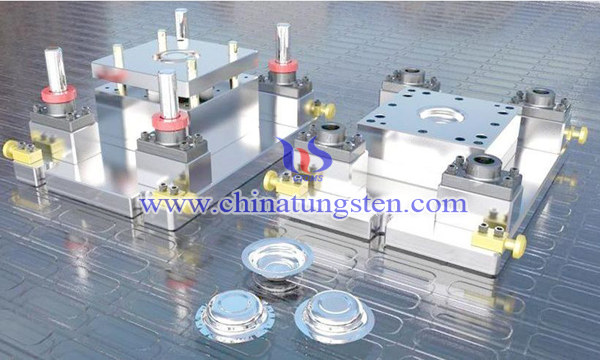

Nano Tungsten Carbide Coating on Die Surface

- Details

- Category: Tungsten Information

- Published on Saturday, 07 September 2019 22:31

With the rapid development of material surface modification technology, thermal spraying, plasma spraying and other technologies are more and more widely used in the die. After the traditional die is used for a long time, the surface of the die will be damaged, cracks and other problems, maintenance troubles, and need to replace the new die.

Coarse Single Crystal Tungsten Carbide Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 07 September 2019 21:54

Hard metal is regarded as a kind of composite material, in which WC phase is used as hardness carrier. The brittleness of pure WC related to high hardness can be compensated by metal binder phases (usually Co, or Fe and Ni and their alloys and optional Cr). When the content of binder is high, the mechanical wear resistance is not enough, but when the content of binder is low, the mechanical strength is not enough.

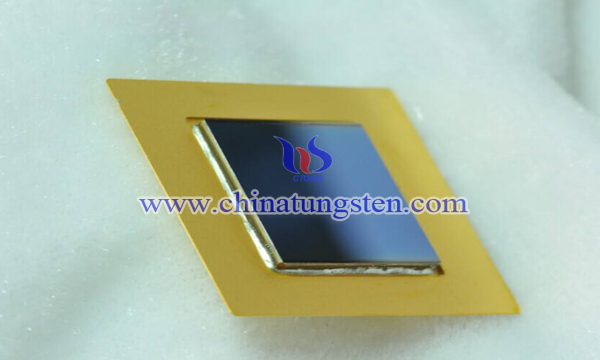

Tungsten-containing Composite Films Preparation by Homogenizing

- Details

- Category: Tungsten Information

- Published on Saturday, 07 September 2019 21:46

Tungsten-containing material is the best high-energy radiation shielding material. It has excellent attenuation and absorption ability to X-ray and radioisotope radiation, which is more than 40% higher than the commonly used lead. It has been widely used in medical diagnosis and treatment, nuclear energy utilization, product safety inspection, industrial flaw detection and other fields.

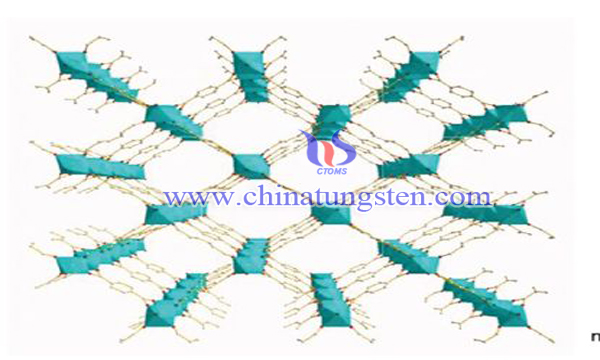

MIL-loaded Phosphotungstic Acid

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 23:26

Photocatalytic oxidation technology has good selectivity, can react at room temperature and pressure under mild conditions, and can degrade organic pollutants into non-toxic and harmless inorganic substances. It is a green technology with important application prospects in the field of energy and environment. In recent years, more and more reports have been reported on photocatalytic oxidation of organic wastewater. Semiconductor materials used are also various, such as titanium dioxide, zinc oxide, Fe2O3, CdS, WO3, etc. The photocatalytic stability of WO3 is good, but its activity is relatively small.

Tungsten Alloy Ultra-thin Plate Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 23:17

Tungsten alloys are alloys based on tungsten with other metals. They have small size, high density, high melting point, high hardness, high wear resistance, high ultimate tensile strength, good ductility, low vapor pressure, high temperature resistance, good thermal stability, corrosion resistance, good seismic resistance, extremely high radiation absorption capacity and excellent impact resistance. It is widely used in industry, military, scientific research, medical treatment, sports and other fields because of its excellent properties such as strength, crack resistance and non-toxicity.

Niobium Tungsten Hafnium Superalloy Synthesis Scheme

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 23:02

At present, the highest working temperature of the most mature and widely used niobium tungsten hafnium superalloy in the high temperature field is 1050 ~1150 ℃, which has reached 80%~85% of the melting point of the Ni-based superalloys. In order to meet the service conditions of high temperature strength and room temperature plasticity of spacecraft in the temperature range of 1200 1400 ℃, new super high temperature alloy materials with refractory metal matrix are still being developed in China.

Molybdenum Tungsten Lanthanum Alloy Wire

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 22:37

The addition of lanthanum to pure molybdenum not only improves the strength and toughness of molybdenum, but also increases the recrystallization temperature of molybdenum and improves its high temperature resistance. Therefore, lanthanum-doped molybdenum alloys are used to replace pure molybdenum in the preparation of electric heating materials, wire cutting electrode materials, electric light sources and other industries.

High Performance Tungsten Carbide Ceramic Materials

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 21:54

Tungsten carbide ceramics are widely used in aerospace, machinery industry, electronic power, armor, chemical industry and other fields because of their excellent performance in strength, wear resistance and corrosion resistance. Among the various properties mentioned above, the hardness of tungsten carbide is still insufficient compared with the other properties. Therefore, how to improve the hardness of tungsten carbide so as to achieve a balanced performance in all aspects, so that it is more suitable for various fields.

Supported Tungsten-gallium Polyoxometalate Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 21:40

Epoxides are a kind of fine chemical raw materials and pharmaceutical intermediates with wide applications. The most important way to form epoxides is the epoxidation of olefins. Epoxidation plays an important role in both organic synthesis and chemical industry. Therefore, the study of olefin epoxidation has always been a hot spot in chemical industry.

How to Prepare Titanium Tungsten Silicon Composite Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 03 September 2019 21:30

With the continuous concern of haze, the control of air pollution has become more and more important. Nitrogen oxides are one of the main air pollutants and important precursors to induce photochemistry smog and acid rain. About 60% of them are discharged from coal-fired power plants, industrial boilers and cement plants.

sales@chinatungsten.com

sales@chinatungsten.com