Weight Reduction Plan for Cerium Tungsten Alloy Wire

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:43

Compared with traditional thorium tungsten alloy wire, cerium tungsten alloy wire has lower electron escape work (only 2.8eV, 10% lower than thorium-tungsten alloy wires), higher emissivity (27 times higher than thorium-tungsten alloy wires at 1500K), higher luminescence efficiency (10-15% higher than thorium-tungsten alloy wires), lower arcing voltage (about 40% higher than thorium-tungsten alloy wires), and no human body. The radioactive pollution produced by the body is a good product of green environmental protection. It can be used to replace thorium tungsten alloy wires in electron emission tubes, argon arc welding, etc. It has very broad application prospects in high-demand electric light sources.

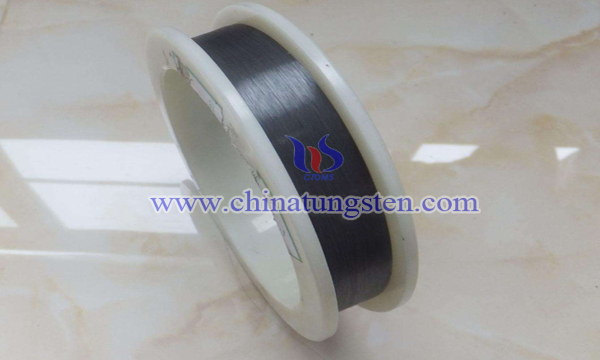

The processing of cerium tungsten alloy wire belongs to the deformation processing of refractory metal, and it is a deep processing in tungsten field. At present, with the rapid development of plasma arc and laser technology at home and abroad, the performance of W-Ce alloy wires has been put forward higher requirements. At present, the tungsten cerium alloy produced in China has few wires that can be processed to below 0.80mm. The homogeneity of Ce-W doping is difficult to control, and the drawing process is also difficult. The yield of filament processed to 0.39 and below is even more difficult to see.

In order to overcome the shortcomings of the existing technology, some scholars have provided a preparation method of aseismic and environmentally friendly cerium-tungsten alloy wire. The preparation method is simple and easy to use, with high yield and strong controllability of drawing. The preparation process is as follows:

1.Ammonium paratungstate with square monoclinic crystal is selected and its particle size is controlled from 30 to 50 microns. It has high activity, good fluidity and filling property. Blue tungsten oxide can be obtained by slight reduction, and good high temperature and processing performance can be obtained. When doped with Al(NO3)3 solution, K2SiO 3 solution and Co(NO3)2 solution, its elements such as Al and Co(NO3)2 can be promoted. Potassium entering into tungsten matrix can obviously reduce the low temperature brittleness of tungsten wire, reduce the splitting of tungsten wire, and make the tungsten wire have good high temperature droop resistance.

2.After mixing, one part is directly reduced once, and the other part is reduced in two stages. The first stage is 550-660 ℃, the second stage is 610-810 ℃, and the ratio of potassium and cobalt is 4:6. The high temperature seismic performance of tungsten wire can be improved. The second stage will be reduced twice. After 30-40 hours of pickling, the raw materials were vacuum-dried at 80-120 ~℃. After pickling, cerium nitrate solution was added to the raw materials. The cerium element has high heat resistance, high emissivity, light-emitting efficiency, low arcing voltage and no radioactive pollution. The properties of the raw materials are good.

3.After burning, the first reduction is carried out between 750 and 800 ℃, the second reduction is carried out between 900 and 950 ℃, the second reduction is carried out between 900 ℃ and 950 ℃, the second reduction is carried out between 900 ℃ and the second reduction is carried out between 900 degrees ℃ and 950 ℃. Vertical melting sintering at sub-high temperature ensures the crystallinity of tungsten bars, reduces the production cost, increases the density of tungsten bars, makes the grain size uniform and the high temperature performance of tungsten wires good.

4.Adopting multi-machine spinning and calcining method to improve production efficiency, save energy, ensure better uniformity of products, crystallization annealing, recrystallization annealing and stress relief annealing; alternating with spinning forging, it can be machined to 3.8mm; multiple annealing can eliminate stress on the surface of tungsten wire in time and reduce cracks of tungsten wire. . The processing stress is eliminated, the blockage of dislocation is reduced, the plastic deformation ability of metal is restored, the anti-sagging property of tungsten wire at high temperature is improved, and the tungsten wire is fine-drawn to produce finished tungsten wire.

By adding dopants containing elemental elements such as barium, potassium and cobalt, the distribution of elements in the produced tungsten alloy billets can be more uniform, the wire winding performance is good, the seismic performance of the tungsten wire is increased, the product yield is high, and the service life is long. It can be processed to Φ0.39mm, which can be widely used in aerospace, aviation, optoelectronics, information technology engineering, lighting and other fields.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com