Tungsten Carbide Studs Used in The Car Tire

- Details

- Category: Tungsten Information

- Published on Monday, 26 November 2018 09:31

Are you in the heat of the northern hemisphere? Still in a corner of the southern hemisphere? No matter how! When you turn around, you will always rotate again! Then, it should always meet the studs on the car tires. After all, the studs will always appear in cold and humid areas. Tungsten carbide studs are mainly embedded in car tires to prevent the car from slipping on wet skating surfaces and have a very broad market in many European countries.

Recovery of Monoclinic Tungsten Trioxide from Waste Tungsten Slag

- Details

- Category: Tungsten Information

- Published on Sunday, 25 November 2018 18:33

In the process of preparation of tungsten products and elimination of waste products, a large number of secondary resources containing tungsten will be formed. Recovering tungsten from secondary resources will not only improve the quality of tungsten, but also realize resource recycling. At present, the recovery and utilization of tungsten slag is mainly divided into three parts: (1) recovering valuable metals; (2) using tungsten slag as mineral material to produce wear-resistant materials; (3) producing tungsten slag glass-ceramics.

Graphene Modified Tungsten Carbide Self-lubricating Wear-resistant Additive

- Details

- Category: Tungsten Information

- Published on Sunday, 25 November 2018 18:21

Graphene is a new kind of carbon material, which is closely packed with carbon atoms into a single two-dimensional honeycomb lattice structure. It is the basic unit of building the most commonly used solid lubricant - graphite. It has lower friction coefficient than graphite. It is a new kind of additive for self-lubricating antiwear coating.

Tungsten Coating Carbon Fiber Based Heat Insulation Material

- Details

- Category: Tungsten Information

- Published on Sunday, 25 November 2018 18:02

At present, carbon fiber-based thermal insulation material is widely used in vacuum heat treatment furnace, cemented carbide sintering furnace, single crystal silicon drawing furnace and polycrystalline silicon ingot furnace. It has the advantages of small thermal conductivity, low thermal capacity, low density, small linear expansion coefficient, high temperature resistance, strong thermal shock resistance and strong chemical corrosion resistance.

One-Dimensional Tungsten Nitride Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 25 November 2018 17:40

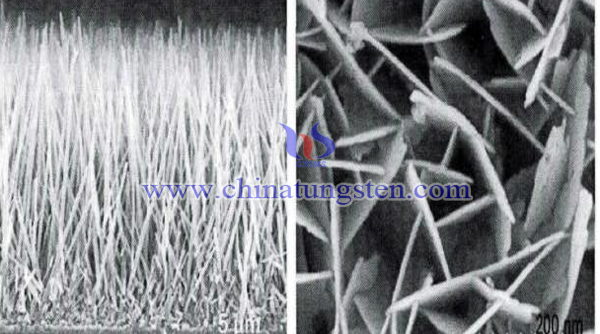

With the progress of science and technology and the development of society, nano-materials have gradually penetrated into various fields. One-dimensional nanomaterials, due to their unique structure and properties, have wide application prospects in optoelectronic devices, catalysis, energy storage and sensors.

Manufacturing Details of Fine Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Sunday, 25 November 2018 17:33

Tungsten filament has excellent heat resistance and mechanical strength, so as cathode filament of TV electronic gun and filament material of various electrode materials, automobile lamp, lighting lamp of household appliances and photocopier lamp, it is widely used in many forms.

Alkali Decomposition of High Calcium Tungsten Ore by Thermal Ball Milling Improvement

- Details

- Category: Tungsten Information

- Published on Saturday, 24 November 2018 16:46

Tungsten resources are abundant and various in China. At present, wolframite is decomposed by alkali and scheelite is decomposed by hydrochloric acid or boiled by soda. For quite a long time, experts at home and abroad generally believed that it was impossible to decompose scheelite by alkali (NaOH) in industry. Until Professor Li Honggui of Central South University put forward the hot-ball milling alkali decomposition process, which broke the convention.

Low Cost Process for Tungsten Oxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Saturday, 24 November 2018 16:29

When applied voltage to materials, the reversible color change of materials is called electrochromic. Electrochromic materials include organic materials and inorganic materials. Inorganic materials have attracted much attention because of their good cyclic stability. Tungsten trioxide is the representative of inorganic materials.

How to Activate Unbonded Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 23 November 2018 22:42

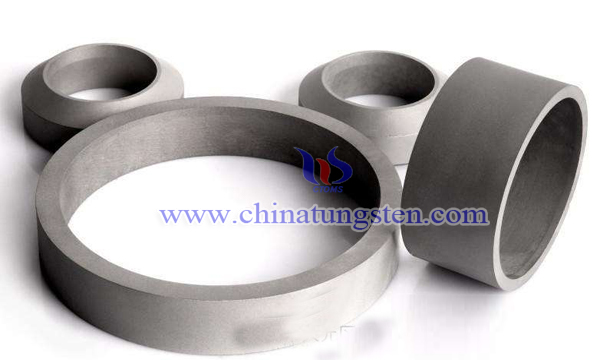

Tungsten carbide cemented carbide is widely used in cutting, drilling, mining, tool forming and wear-resistant parts because of its high hardness, high strength, high toughness, wear resistance, high temperature resistance and low expansion coefficient. Generally speaking, tungsten carbide alloys need cobalt and nickel as bonding phases. Although metal bonding phases promote sintering densification, they also reduce hardness, wear resistance, corrosion resistance, oxidation resistance and so on. At the same time, there are large differences in thermal expansion coefficients between metal phases and tungsten carbide and other hard phases, which lead to the material. Because of the large thermal stress, the application area is limited.

Tungsten Disulfide / Attapulgite Composite

- Details

- Category: Tungsten Information

- Published on Friday, 23 November 2018 22:37

Tungsten disulfide has attracted much attention for its excellent lubricity and catalytic performance. Although tungsten disulfide has excellent properties, its properties still need to be further improved in many cases. Compounds with other inorganic substances are one of the ways to improve its properties.

sales@chinatungsten.com

sales@chinatungsten.com