Tungsten Oxide Hydrogen Sensor

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 16:56

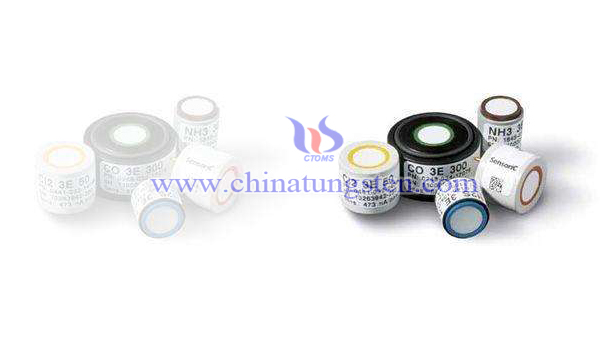

In industrial production, hydrogen, as a non-polluting green energy, has attracted wide attention. However, hydrogen is volatile, low ignition point, colorless and tasteless. It is a very dangerous flammable gas when it encounters open fire when its concentration in air is 4-75%. Therefore, the monitoring technology and research of gas sensitive materials for hydrogen play an important role in ensuring personal and property safety.

Tungsten Trioxide Hydrogen Sulfide Gas Sensor

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 16:50

Hydrogen sulfide is a colorless gas with the odor of rotten eggs. Its toxicity is very strong. Its permissible concentration in the air is 10 ppm. The upper and lower limits of explosion range from 4.3% to 46.0%. The harm of hydrogen sulfide gas to human body belongs to chemical nerve toxicity, stimulation and asphyxiation gas, which can destroy red blood cells and cause olfactory stimulation at 0.1 ppm. Therefore, how to quantitatively detect trace hydrogen sulfide gas in the air has become an urgent problem to be solved in relevant workplaces.

Tungsten Oxide Resistance Memory

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 16:41

Tungsten oxide resistance memory is a semiconductor device which can achieve storage by reversible change of resistance value of tungsten oxide material under electric field.

Paper-based Two-dimensional Tungsten Trioxide Nanosheets

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 October 2019 22:57

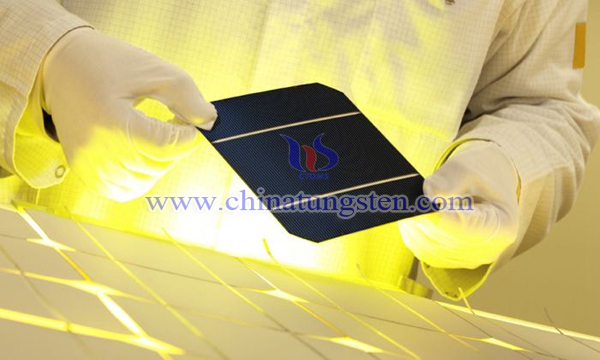

In recent years, flexible perovskite solar cells have attracted much attention, and the flexible substrates used have a great impact on the performance of devices. At present, the commonly used flexible substrates of polyethylene terephthalate (PET) and metal foil can not meet the demand. It is urgent to find a cheap and abundant new flexible substitutes.

Tungsten Oxide Nanoribbon Arrays

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 October 2019 22:51

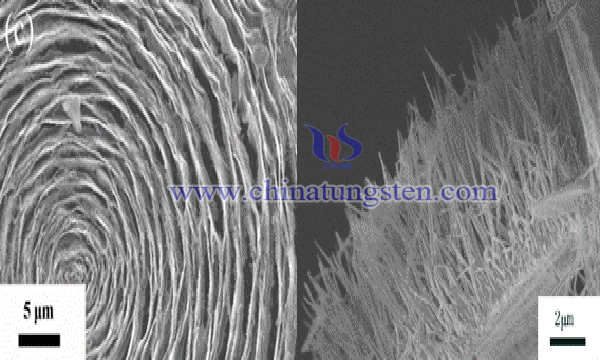

Tungsten oxide is a new functional material, which can be used in chemical sensors, catalytic materials, electrochemical electrodes, electrochromic materials, high temperature superconducting materials, solar energy absorbing materials, wave absorbing stealth materials and so on.

Tungsten Trioxide Photocatalyst Preparation by Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 October 2019 22:43

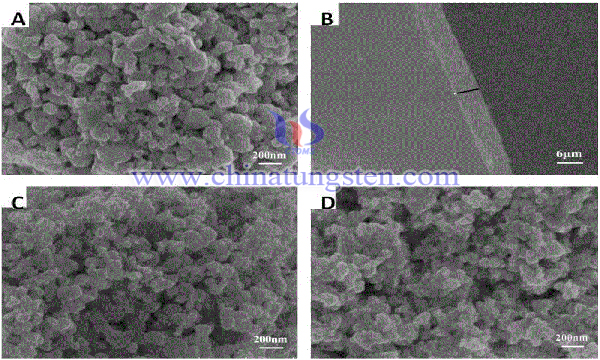

At present, tungsten trioxide has been used in many aspects of daily life, such as the manufacture of X-ray phosphors, refractories and gas sensors. In addition, tungsten trioxide has an important application field, namely photocatalytic degradation materials.

Ultrafine Tungsten Carbide Powder Reduction Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 October 2019 22:33

Ultrafine cemented carbide is a tool material developed in recent years. It is mainly based on ultrafine tungsten carbide powder and adds appropriate binder (such as Co) and grain growth inhibitor to produce high hardness, high wear resistance and high toughness cemented carbide material. Its performance is higher than conventional cemented carbide. It is used in hard-to-machine metal materials tools, micro-drills in electronic industry, precision dies and dies. Medical dental drills and other fields have shown more and more extensive application prospects.

Binary Composite Tantalum Tungsten Cathode

- Details

- Category: Tungsten Information

- Published on Tuesday, 01 October 2019 23:45

Magnetron is currently the most efficient microwave device, and it has a huge application market in the fields of civil heating and radiology. In recent years, with the rapid growth of microwave application markets such as radiology and container inspection, magnetrons continue to develop in the direction of high power, high frequency, miniaturization and low cost.

Preparation Method of Zinc Tungstate Electrochromic Composite Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 01 October 2019 23:24

Electrochromism refers to a stable and reversible change in the color or transmittance of a material under the action of an applied voltage or electric field. At present, electrochromic materials are considered to be one of the most promising smart materials, and it is expected to have great potential application value, such as smart window, automobile anti-glare rearview mirror and electrochromic display.

Tungsten Disulfide Catalysts

- Details

- Category: Tungsten Information

- Published on Monday, 30 September 2019 18:05

There are three main types of tungsten disulfide catalysts that have high chemical activity. They are hydrogenation active catalyst, non-polar functional material catalyst and photocatalyst. Tungsten Disulfide Catalysts have high application value in petroleum industry and other important fields.

sales@chinatungsten.com

sales@chinatungsten.com