Tungsten Trioxide Photocatalyst Preparation by Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 October 2019 22:43

At present, tungsten trioxide has been used in many aspects of daily life, such as the manufacture of X-ray phosphors, refractories and gas sensors. In addition, tungsten trioxide has an important application field, namely photocatalytic degradation materials.

As a semiconductor material, tungsten trioxide can excite electrons from valence band to conduction band under ultraviolet irradiation, generate holes on the surface of tungsten trioxide microparticles, and react with water to form hydroxyl radicals. Hydroxyl radicals have high oxidation activity. Hydroxyl radicals can degrade pollutants in water when they react with organic pollutants. The tungsten trioxide micron particles in the tungsten trioxide powders prepared in the prior art are generally rod-like or sheet-like, and their photocatalytic degradation performance and gas sensing performance are weak. Therefore, the development of tungsten trioxide powder with excellent photocatalytic degradation and gas sensing properties has become a hot topic.

Hydrothermal method is usually used to prepare tungsten trioxide photocatalyst. In order to produce high quality tungsten trioxide powder, researchers have optimized the hydrothermal method. The steps include:

1.3.2990g sodium tungstate dihydrate (Na2WO4·2H2O) was dissolved in 20 mL distilled water to prepare sodium tungstate solution with a concentration of 0.5 mol/L. Then add 35% hydrochloric acid solution and 98% nitric acid solution to the sodium tungstate solution with 0.5 mol/L concentration, adjust the pH of sodium tungstate solution with hydrochloric acid solution and nitric acid solution to 2.75, and stir for 30 minutes after adding hydrochloric acid solution, make the hydrochloric acid solution, nitric acid solution and sodium tungstate solution mix evenly, and get the precursor solution.

2.Transfer the precursor to the reactor and seal the precursor to react in the reactor. The reaction temperature is 170 ℃ and the reaction time is 42 hours. The reaction liquid is obtained. Then the reaction liquid, i.e. the precursor liquid after 42 hours of heating, is cooled to room temperature with the furnace.

3.The cooled reaction liquid is taken out from the reactor, and solid substances are separated from the cooled reaction liquid by centrifugal separation. The speed of centrifugal separation is 4000rpm.

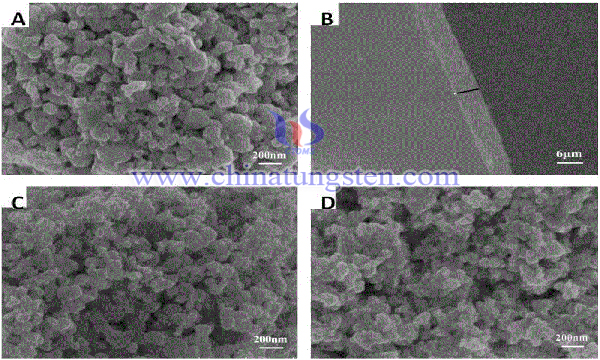

4.Tungsten trioxide powder was obtained by washing and drying solid materials. Among them, 99% of tungsten trioxide microparticles were ellipsoidal in shape.

More than 95% of the ellipsoidal tungsten trioxide microparticles can be obtained by the improved process. The self-assembled morphology of tungsten trioxide nanorods can be maintained steadily, and the ellipsoidal tungsten trioxide microparticles can be formed steadily in large proportion from the self-assembled tungsten trioxide nanorods. The tungsten trioxide powder has high catalytic degradation ability and excellent gas sensing performance after performance testing.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com