Tungsten Trioxide Separation from Waste SCR Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:51

At present, most power plants in our country mainly use coal as fuel. The direct combustion of coal will produce a large number of nitrogen oxides which pollute the environment. At present, flue gas denitrification technology is widely used in developed countries to reduce the emission of nitrogen oxides, and the denitrification rate can reach more than 90%.

Tungsten Trioxide Nanosheets Mechanochemical Method

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:16

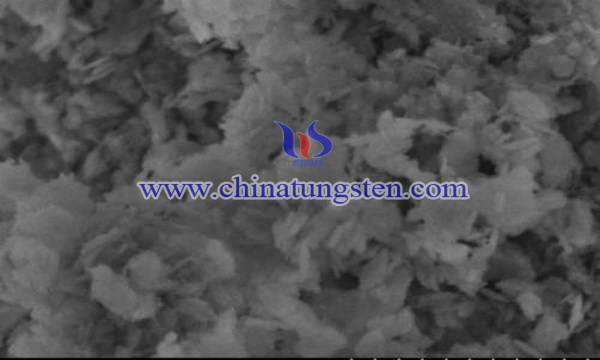

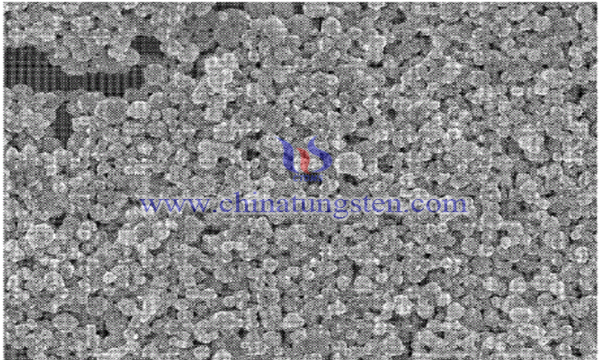

Recently, some scholars have attempted to prepare tungsten trioxide nanosheets with high specific surface area, high crystallinity, high dispersibility and low cost by mechanochemical method. The main process is to prepare tungstic acid (WO3·H2O) nanosheets using tungstic acid-based organic or inorganic layered hybrid micro/nanobelts (tubes) as precursors, and remove the organic matter between the precursor layers by nitric acid oxidation. The reaction temperature is 15-50 ℃. The time is 5-120 H. The tungsten oxide nanosheets are prepared by heating them at a heating rate of 1-5 ℃/min to 250-600 ℃, then holding them for 1-5 h, and then cooling them to room temperature naturally. The specific operation is as follows:

Tungsten Trioxide Carbon Nanotube Composite Films

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:13

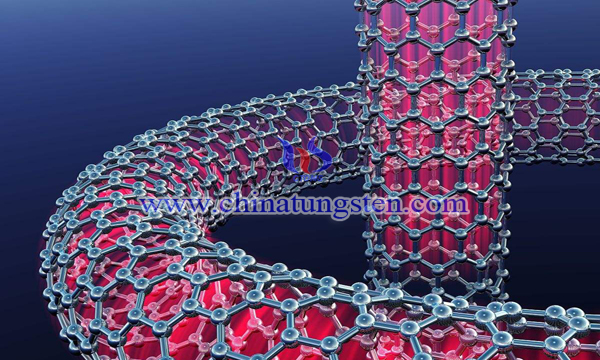

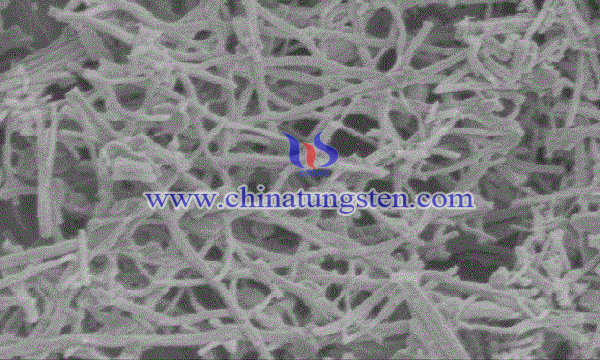

Carbon nanotubes (CNTs) have a special structure consisting of hexagonal networks similar to graphite. Unique nano-hollow structure and closed spiral structure of different topological levels make it have a lot of special excellent properties, such as good electrical conductivity, heat resistance, high mechanical strength, corrosion resistance, self-lubrication and biocompatibility. These excellent properties make carbon nanotubes have great application prospects in composite materials, hydrogen storage materials and catalyst materials.

Ammonium Paratungstate Purification by Extraction Method

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 16:39

Tungsten is an important strategic metal resource. Ammonium paratungstate/tungsten trioxide is an important chemical product of tungsten. Qualified products of ammonium paratungstate and tungsten oxide are produced in tungsten smelting process, or waste materials of ammonium paratungstate and tungsten oxide are collected.

Defective Tungsten Trioxide Preparation

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 22:44

In the research of traditional catalysts, titanium dioxide (titanium dioxide) is widely used to treat various environmental pollution problems by its photocatalytic reaction. However, titanium dioxide can only be stimulated by ultraviolet light, and ultraviolet light only accounts for about 5% of the energy in sunlight. Therefore, there is a problem of insufficient utilization of solar energy. Therefore, researchers are looking for other new photocatalysts, including trioxide. Tungsten oxide (WO3), however, can absorb UV light with wavelength less than 460nm. The utilization of other visible and infrared energy is still low.

Nano Silver Tungsten Oxide Photocatalyst Coatings

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 22:34

There are many materials that can be used as photocatalyst in the world, including titanium dioxide (titanium dioxide), zinc oxide (zinc oxide), tin oxide (SnO2), zirconium dioxide (ZrO2), tungsten trioxide (WO3) and other oxide sulfide semiconductors. Among them, titanium dioxide is the most common Nano-Photocatalyst material in the world because of its strong oxidation ability, stable chemical properties and non-toxic.

Tungsten Trioxide As Anode Material for Lithium Ion Batteries

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 22:01

As an important n-type semiconductor oxide, tungsten trioxide (WO3) is widely used in chemical sensors, photocatalysis, energy conversion systems and other fields. Because of its large theoretical capacity (693 mAh/g), low cost and high safety (high melting temperature and mechanical stability), tungsten trioxide can also be used as negative electrode materials for lithium ion batteries.

Tungsten Oxide Quantum Dots Synthesis by Ultrasound Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 18:20

Quantum dots (QDs) are a new kind of nano-fluorescent materials. Because of their unique electrical and optical properties, QDs have been widely used in physics, chemistry, biology and other fields. As a new fluorescent material.

Waste Tungsten Oxide Recycle and Treatment

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 18:14

At present, the existing processes for recovering and treating waste tungsten oxide to produce ammonium tungstate solution, ammonium paratungstate and ammonium metatungstate are all based on the chemical properties of all tungsten trioxide and blue tungsten oxide which are insoluble or slightly soluble in ammonia water and only soluble in caustic soda or soda ash. The process is to dissolve oxygen in normal pressure or pressure boiling with caustic soda (sodium hydroxide) solution or soda carbonate solution in advance. Tungsten carbide is prepared into sodium tungstate solution, or tungsten oxide is melted with sodium carbonate at high temperature, then tungsten is boiled and leached to form sodium tungstate solution.

Porous Silicon Composite One-Dimensional Tungsten Oxide Nanostructured Gas Sensitive Materials

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 17:51

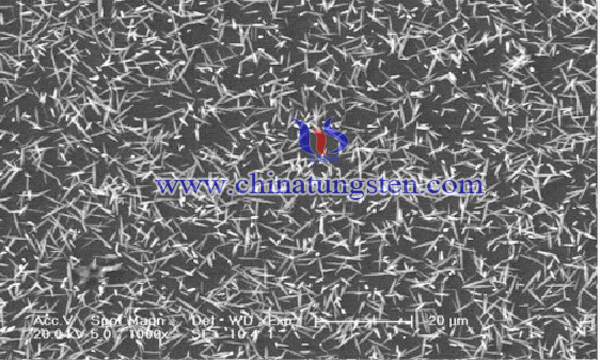

Nitrogen oxide (NOx), as a highly toxic gas, is the main source of acid rain and photochemical smog, which has posed a serious threat to human health and safety. Therefore, the detection of nitrogen oxides has become a research hotspot in recent years.

sales@chinatungsten.com

sales@chinatungsten.com