Tungsten Trioxide Carbon Nanotube Composite Films

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:13

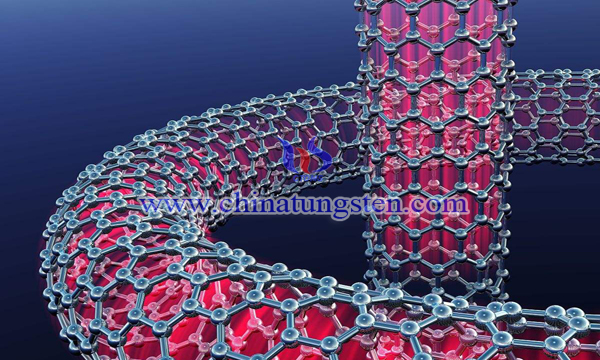

Carbon nanotubes (CNTs) have a special structure consisting of hexagonal networks similar to graphite. Unique nano-hollow structure and closed spiral structure of different topological levels make it have a lot of special excellent properties, such as good electrical conductivity, heat resistance, high mechanical strength, corrosion resistance, self-lubrication and biocompatibility. These excellent properties make carbon nanotubes have great application prospects in composite materials, hydrogen storage materials and catalyst materials.

Tungsten trioxide is a kind of transition metal oxide. The composite materials of tungsten trioxide and carbon nanotubes have broad application prospects in gas sensors, photocatalysts, electrochromic devices and other fields. However, at present, there are still some shortcomings in the preparation of carbon nanotubes tungsten oxide composites. The main manifestations are as follows: 1) the crystal structure of tungsten oxide is not controllable, and different morphologies of tungsten oxide crystals can not be obtained; 2) it can not be prepared in large quantities and needs many steps; 3) the macrostructure of carbon nanotubes is not controllable. In view of the shortcomings of the existing technology, some scholars have prepared a tungsten oxide carbon nanotube composite film. The process is as follows:

Ordered carbon nanotubes (CNTs) films were drawn from the CNTs arrays of the pullable films, and the CNTs with the same multilayer orientation were laid on the 2cm x 5cm-sized scaffolds. Refer to Figure 1. Place a flat carbon nanotube film bracket on a W (ph) 6 container and place it in a 2-inch tube oven. Then, the furnace is heated. When the temperature of the furnace rises to 300 ℃, the heating stops after 30 minutes to let the furnace cool naturally. When the temperature of the furnace drops to room temperature, the support is removed from the furnace and the core-shell structure composites of multi-layer tungsten oxide carbon nanotubes with the same orientation are obtained.

The above-mentioned tungsten oxide-carbon nanotube-wrapped nanotube film material was used for electrochromic experiments. The solution was a 1 M HClO4 solution, the working electrode was a tungsten oxide carbon nanotube composite material, and the reference electrode was an Ag/AgCl electrode. The electrode was a platinum plate, and a voltage of -1 V was applied to the working electrode of the WO3/CNT composite film, and the film became blue; then, a voltage of 1 V was applied to the WO3/CNT electrode, and the film was returned to the original state.

The above method for preparing a tungsten monoxide carbon nanotube composite film can adjust the size and orientation of the composite material by adjusting the size structure of the carbon nanotube film, and can well replace the electrochromic material based on expensive conductive base materials such as ITO and FTO. And has the characteristics of cost saving, flexibility, translucency and so on.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com