Tungsten Trioxide Nanosheets Mechanochemical Method

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:16

Recently, some scholars have attempted to prepare tungsten trioxide nanosheets with high specific surface area, high crystallinity, high dispersibility and low cost by mechanochemical method. The main process is to prepare tungstic acid (WO3·H2O) nanosheets using tungstic acid-based organic or inorganic layered hybrid micro/nanobelts (tubes) as precursors, and remove the organic matter between the precursor layers by nitric acid oxidation. The reaction temperature is 15-50 ℃. The time is 5-120 H. The tungsten oxide nanosheets are prepared by heating them at a heating rate of 1-5 ℃/min to 250-600 ℃, then holding them for 1-5 h, and then cooling them to room temperature naturally. The specific operation is as follows:

(1) Preparation of Tungstate-based Organic/Inorganic Layered Hybrid Microbelts/Nanotubes

Layered tungstic acid (H2W2O7·xH2O, x=0.2-5.0) was added to the mixture of alkylamine (CH3·(CH2)nNH2 (3 < n < 17)/nonpolar solvent (liquid alkanes at room temperature) and reacted at ambient temperature (15-50 ℃) for 10-120 H. The molar ratio of CH3(CH2)nNH2 to H2W2O7·xH2O is (15-40):1, the volume ratio of non-polar solvent to alkylamine is (1-10):1, and the product is decompressed and dried at room temperature for 524 hours. The white solid obtained by drying is tungstate-based organic or inorganic layered hybrid micro/band (tube), with an apparent diameter of 200-700 nm and a length of 5-20 um.

(2) Removal of Interlayer Organic Compounds from Organic/Inorganic Layered Hybrid Precursors by Oxidation

The solid tungstate-based organic/inorganic layered hybrid micro/nanoribbons (tubes) were dispersed in 1-10 mol/l nitric acid solution, and the bright yellow suspension was obtained by magnetic stirring reaction at 15-50 ~℃ for 5-120 H. After centrifugal separation, the product was dried at 120 ~℃ for 5-12 h, and the orthogonal phase WO3·H2O nanosheets were obtained. The area of the WO3·H2O nanosheets was (100-800) nm ((100-800) nm) and the apparent thickness was 5-40 nm.

(3) Conversion from WO3·H2O nanosheets to WO3 nanosheets

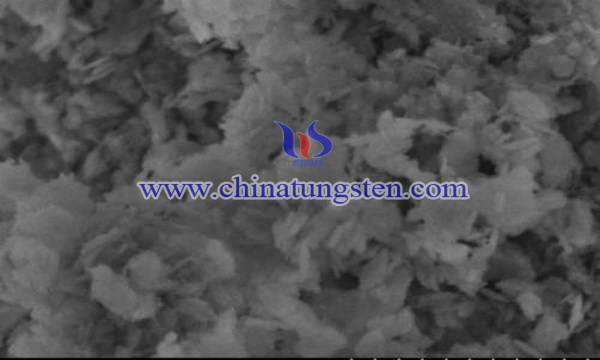

The WO3·H2O nanosheet powder was placed in a covered aluminium oxide crucible. The crucible was placed in an electric furnace with programmable temperature control. The air atmosphere was heated at a heating rate of 1-5 ℃/min to 250-600 ℃, then kept for 1-5 h, and then cooled naturally to room temperature. The product was monoclinic WO3 nanosheet, which was light yellow powder with fluffy appearance. Its single crystal nanosheet size and WO3 nanosheet size were obtained. The BET specific surface area of WO3 nanosheets can reach 100-250 m2/g with the area of (100-800) nm * (100-800) nm and the apparent thickness of 5-40 nm.

Tungsten trioxide nanosheets prepared by mechanochemical method have the advantages of high efficiency, low cost, good repeatability, large production scale and excellent product performance.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com