Thermal Stability of Tungsten Disulfide in Gaseous Mediums

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 September 2019 19:11

Thermal stability of tungsten disulfide varies in different gaseous mediums or gas states. Tungsten disulfide can be heated and react not only in air but also in vacuum. Usually, hydrogen, argon and nitrogen are needed in the preparation of tungsten disulfide.

.jpg)

Thermal stability, also known as heat resistance, refers to the deformation capacity of substance under the influence of temperature. The smaller the deformation, the higher the thermal stability. Generally, we can judge the thermal stability of a substance by observing the phenomena during the heating.

Thermal stability of tungsten disulfide is as follows:

1. In air (O2)

When heated in air, tungsten disulfide reacts with oxygen to form sulfur dioxide and tungsten trioxide with low friction coefficient. The higher temperature and the smaller tungsten disulfide particles lead to the more active reaction.

2. In vacuum

When heated in vacuum, tungsten disulfide can release a small amount of gas. It can slowly decompose into sulfur and tungsten when heated to above 1100°C. And when heated to 1250°C, it is decomposed completely.

.jpg)

3. Hydrogen (H2)

Tungsten disulfide produces tungsten and hydrogen sulfide when heated to about 80°C in hydrogen. The chemical reaction is as follows:

1/2 WS2 (solid) +H2 (gas) ←→H2S (gas) +1/2 W (solid)

The relationship of the equilibrium constant K and reaction temperature T at low temperature is different from that at high temperature, which is caused by different crystalline states of tungsten disulfide.

4. Nitrogen (N2)

Tungsten disulfide is stable in nitrogen.

5. Argon (Ar)

Tungsten disulfide loses a small amount of sulfur when heated to more than 1000°C in argon.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Batch Synthesis of Tungsten Trioxide Nanosheets

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:48

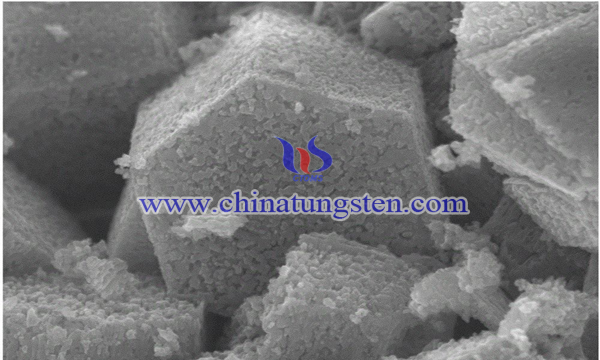

Nanomaterials have become one of the hotspots of current research due to their unique physical and chemical properties, such as high specific surface area, quantum size effect, small size effect and macroscopic quantum tunneling effect. In recent years, many Nano-Research centers have been established in China, and some remarkable achievements have been made in catalysis, gas sensing and other fields.

Copper-supported Tungsten Oxide Nanotubes

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:33

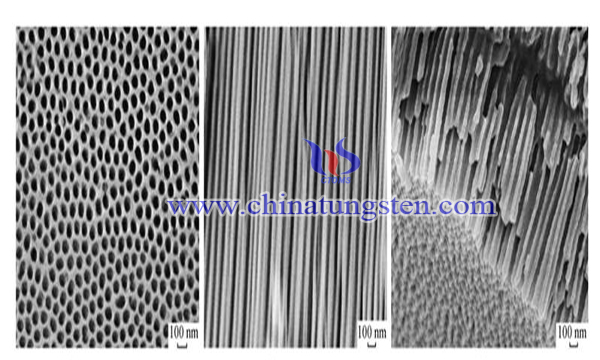

In the field of semiconductor photocatalysis, titanium dioxide has been widely studied, but its bandgap is wide (3.2ev). Only ultraviolet light can excite it to produce photogenerated carriers. In sunlight, the proportion of ultraviolet light is very small, so the utilization of sunlight in pure titanium dioxide photocatalysis process is very low.

One-step Hydrothermal Method of Tungsten Oxide Quantum Dots and Tungsten Oxide Nanowires

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:20

Tungsten oxide is a kind of tungstic anhydride and a kind of tungstate product. Tungsten oxide includes trioxide and tungsten dioxide. Tungsten oxide is partly used in the production of chemical products, such as paints and coatings, petroleum industrial catalysts, etc. But tungsten oxide is more an intermediate product and is widely used in the preparation of tungsten metal powder and tungsten carbide powder. It is used in the production of tungsten metal products and a large number of tungsten alloy products.

Tungsten Oxide Photocatalyst Loaded with Platinum Particles on the Surface

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:05

When a semiconductor irradiates light with energy above bandgap, the electrons of valence band excite in the conduction band, generate holes in the valence band, and generate electrons in the conduction band. They have strong oxidation and reduction abilities respectively, and have redox effects on molecular species in contact with semiconductors. Such an action is called photocatalysis, and such semiconductors are called photocatalysts.

One-dimensional Tungsten Oxide-Vanadium Oxide Heterojunction Nanowire Arrays

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 21:52

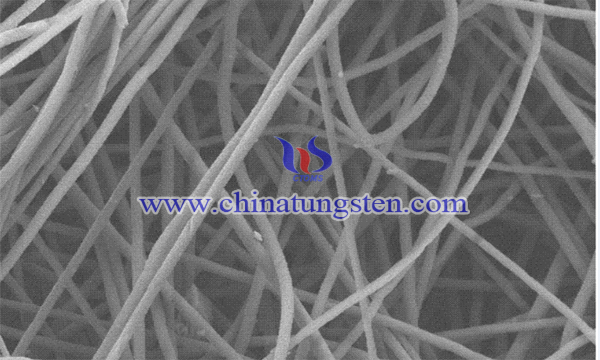

The active atoms of tungsten oxide are located on the surface of the crystal, which greatly enlarges the contact area between the crystal surface and the gas, and can effectively improve the gas sensing performance. Tungsten oxide with one-dimensional nanowire structure attracts many researchers because of its huge specific surface area.

Stepwise Synthesis of Tungsten Trioxide-Polyaniline-Graphene Composites

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 21:42

In recent years, graphene, conductive polymers and transition metal oxide composites have attracted more and more attention of researchers, and have become one of the foreword fields of electrochemical research.

Ball Milling Method for Tungsten Carbide-based Hard Alloy Thermal Spray Powder

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 21:29

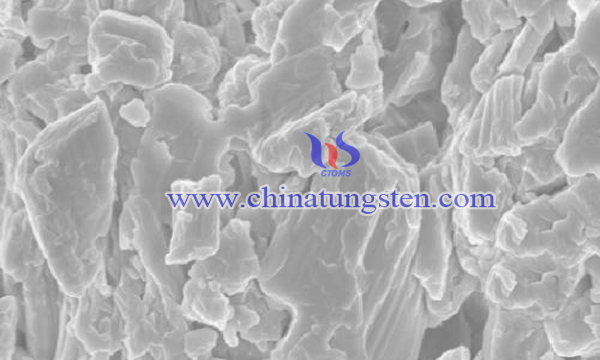

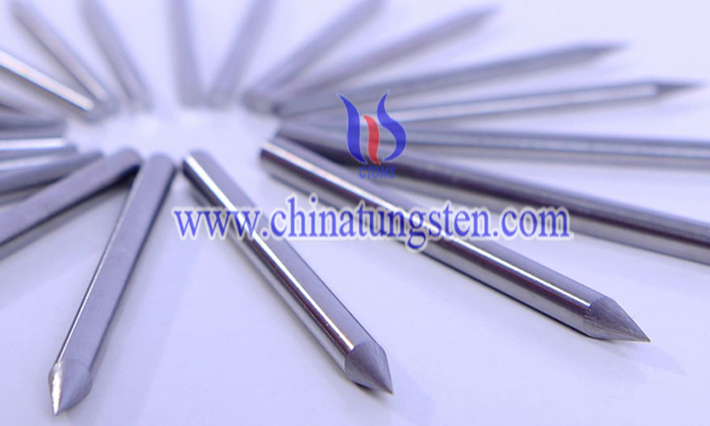

Thermal spraying of cemented carbide powder is a technology of hardening and strengthening mechanical surface. This technology may effectively prolong the service life of machinery. Tungsten carbide is the most common raw material for thermal spray welding (coating). Nowadays, there are many new technologies on the market, such as high-energy plasma spraying, vacuum plasma spraying, supersonic flame spraying, explosive spraying and so on. Whatever process is adopted, the raw materials for spraying are not made of high-quality tungsten carbide powder.

Nanometer Tungsten Disulfide Electrode Materials

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 September 2019 11:03

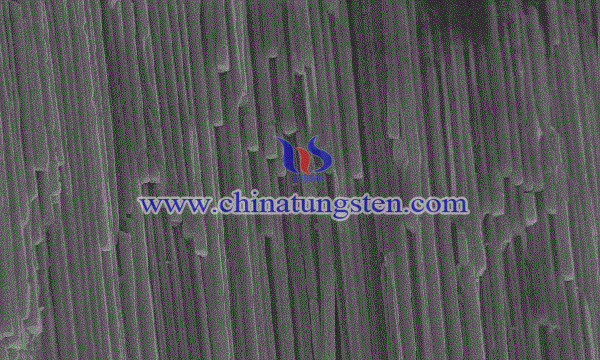

Nanometer tungsten disulfide electrode material, with high specific capacity, large specific surface area and good thermal stability, is considered as an ideal energy storage electrode material, widely used in the field of electrical materials.

The Reason of WS2 Grease Good Lubrication Performance

- Details

- Category: Tungsten Information

- Published on Wednesday, 11 September 2019 10:52

WS2 grease has good lubrication performance, and can still play a good lubrication effect on mechanical equipment in high temperature, high pressure, high vacuum and other harsh working environments. What are the reasons for this?

sales@chinatungsten.com

sales@chinatungsten.com