Batch Synthesis of Tungsten Trioxide Nanosheets

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:48

Nanomaterials have become one of the hotspots of current research due to their unique physical and chemical properties, such as high specific surface area, quantum size effect, small size effect and macroscopic quantum tunneling effect. In recent years, many Nano-Research centers have been established in China, and some remarkable achievements have been made in catalysis, gas sensing and other fields.

The preparation methods of nano tungsten oxide materials can be summarized as liquid phase chemical method and chemical vapor deposition method. Among them, liquid-phase method is one of the most important methods for its low cost and easy to synthesize in large quantities. It is reported that tungsten oxide nanosheets can be prepared by wet chemical method using H2W2O7 as precursor. However, the preparation of tungsten oxide nanosheets is seriously hindered by the high cost and difficult synthesis of H2W2O7. Therefore, some scholars have tried new methods, such as batch synthesis of tungsten trioxide nanosheets by using cheap and readily available tungstic acid as raw materials. The process includes:

1.After fully mixing 20 mL isopropanolamine and 40 mL ethanol, 4 g tungstic acid and tungstic acid layered structure were added. At room temperature, after 120 hours of magnetic stirring, the color of tungstic acid changed from light yellow to Milky white. After centrifugation, white solid was obtained. The obtained samples were washed twice with ethanol and dried at room temperature and low pressure. The white powder was tungstic acid-organic intercalation compound.

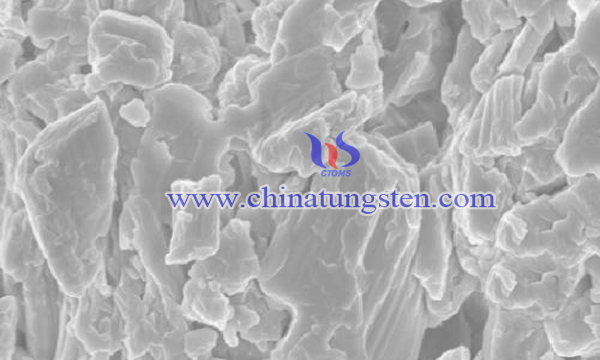

2.White powder was added to 50 mL 5 M nitric acid solution, magnetic stirred for 12 hours, ethanol was centrifugally separated and cleaned to obtain yellowish tungstic acid (WO3·2H2O) nanosheets. The nanosheets were then placed in an alumina crucible and heated to 500 ℃ at a rate of 5 ℃/min, cooled in air for 2 hours, and then cooled to room temperature to obtain tungsten trioxide nanosheets.

The above process is simple and easy to operate, requires low equipment, and uses tungsten or acid having a size of micron or millimeter as a raw material, thereby achieving large-scale stable production and significantly reducing the preparation cost of the tungsten trioxide nanosheet, and also applying a trace amount of noble metal doping. The tungsten trioxide nanosheets have a fast response to gases such as hydrogen sulfide and are good gas sensitive materials.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com