Tungsten Oxide Photocatalyst Loaded with Platinum Particles on the Surface

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:05

When a semiconductor irradiates light with energy above bandgap, the electrons of valence band excite in the conduction band, generate holes in the valence band, and generate electrons in the conduction band. They have strong oxidation and reduction abilities respectively, and have redox effects on molecular species in contact with semiconductors. Such an action is called photocatalysis, and such semiconductors are called photocatalysts.

Tungsten oxide can not show high photocatalytic activity when it is irradiated by visible light but not ultraviolet light. It needs to be doped with metal to improve its photocatalytic activity. Some scholars have developed a kind of tungsten oxide photocatalyst which is prepared by carrying platinum particles on the surface of tungsten oxide particles. The manufacturing process of the photocatalyst is as follows:

1.Fineness is 0.046, 0.215 and 5.726 microns, respectively. D90/D10 is 124. The surface area of BET is 6.0 m2/g. The tungsten oxide particles with a primary particle size of 140 nm are dispersed in water of 50 mL. After 5 minutes of ultrasonic irradiation, the particles with large particle size are separated by a centrifuge at a rotating speed of 1000rpm for 10 minutes to settle. D10, D50 and D90 were 0.074, 0.131 and 0.365 microns, respectively. D90/D10 is 4.93. The surface area of BET is 8.5m2/g and the primary particle size is 99 nm.

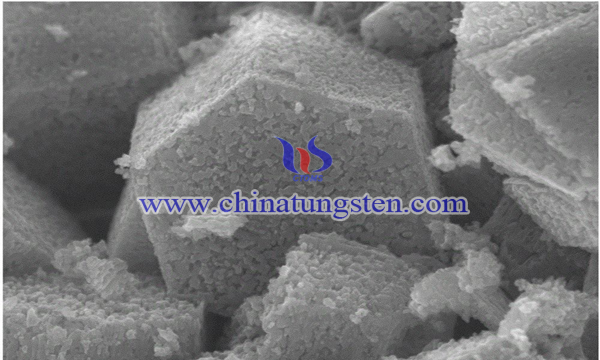

2.Disperse 0.5g tungsten oxide particles in 50 mL of water, and add 0.019 mol/L hexachloroplatinic acid aqueous solution (H2PtCl6) in order to make the weight of Pt equal to 100 parts of tungsten oxide particles 0.5 parts, and irradiate visible light for 2 hours while stirring. The light source uses xenon lamps (300W, Cermax) equipped with ultraviolet blocking filters. After that, 5 ml methanol was added to the upper tungsten oxide particle dispersion solution, and the visible light was irradiated for 2 hours as above while stirring. After filtration, water washing and drying at 120 ~C, the particle-like tungsten oxide photocatalyst loaded with Pt was obtained. The surface of the photocatalyst was observed by SEM and STEM.

Through SEM and STEM observation, tungsten oxide particles with a particle size of 10-20 nm were loaded on the surface of tungsten oxide particles. Further, in the state of several particles joining each other, they were separately loaded. Further observation of these particles by STEM-EDX showed that these particles contained a particle size of 5 nm at one time.

The photocatalyst was used to decompose acetic acid under visible light. The rate of carbon dioxide formation is 190 micromol/h.

Using the above-mentioned photocatalysts, acetaldehyde was decomposed under visible light irradiation. The amount of carbon dioxide generated during 0-30 minutes of light irradiation was 12.4 micromol, 13.2 micromol during 30-60 minutes, and 0.3 micromol during 60-90 minutes. The concentration of acetaldehyde was 0 micromol 55 minutes after illumination. The total decomposition of acetaldehyde is determined by the reduction of acetaldehyde and the amount of carbon dioxide generated.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com