Green and Energy-saving Separation of Tungsten-Tin Ore

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 22:31

There has always been a low (poor) grade tungsten-tin associated ore in the tungsten-tin production industry, which is particularly common in Yunnan. Because the material and chemical properties of the two metal compounds are similar, the separation of the two metals in the industrial production process has always been a difficult problem that puzzles the industrial production technology. The traditional production method has been characterized by high pollution and high energy consumption, which makes it difficult to conform to the national industrial policy.

Silver-coated Tungsten Carbide Powder for Electrical Contact Materials

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 22:23

Electrical contacts are the key components of switchgear, which bear the function of conducting current. Their performance directly affects the reliability and service life of switchgear. Therefore, switchgear requires electrical contacts to have good conductivity and thermal conductivity, low contact resistance and temperature rise, high resistance to fusion welding and electrical erosion.

Tungsten Oxide Nanowires Preparation by Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 22:17

Tungsten oxide nanowires are a kind of magical one-dimensional material, which can also be used to absorb radar electromagnetic wave, such as stealth fighter coatings, strategic missile concealment and so on.

Tungsten Oxide Quantum Dots and Tungsten Oxide Nanowires as Microwave Absorbing Materials

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 22:07

Tungsten oxide has unique physical properties such as photochromism, electrochromism, thermochromism and gas sensitivity. Its color change can be achieved by changing irradiation wavelength, temperature or applied voltage. Therefore, tungsten oxide can be used in many fields, such as sensors, electronic devices and so on. The nature of Yue Yue, its development and research has become a hotspot all over the world.

Advanced Nano Tungsten Powder Manufacturing Scheme

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 21:25

With the development of high technology, the requirement for pure tungsten and its alloy materials is higher and higher. Whether tungsten wire, plate, foil, or other alloy materials based on tungsten (such as tungsten-copper electrical alloy, Tungsten-Nickel-Iron high specific gravity alloy, etc.) are required to have uniform structure, fine grain size and good plasticity. It also promotes the quality requirement of original tungsten powder. In the application, the particle size of advanced nano tungsten powder determines the powder metallurgy process and material properties of tungsten products. Nano-scale ultra-fine tungsten powder is becoming popular.

Metallographic Preparation of Plasma Sprayed Tungsten Carbide Coating

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:48

Tungsten carbide coating by plasma spraying is mainly used for anti-sliding friction, vibration friction, wear resistance and corrosion protection of aero-engines below 500 ℃. It has been widely used in aero-engines at home and abroad.

Molybdenum Silicide Coating for Niobium Tungsten Alloy Combustor of Engine

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:23

Bipropellant attitude and orbit control engine is an important part of modern space vehicles and strategic and tactical weapons, which is widely used in orbit control, attitude adjustment and so on. In recent years, with the development of new aircraft or weapons, the requirement for engine performance has been increasing. It requires that specific impulse be increased and chamber pressure be increased, so as to reduce propellant consumption and engine weight, prolong engine life or increase the range of strategic weapons.

A Tungsten Lubricating Oil Additive

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:12

Diesel engine oil is mainly composed of paraffin base oil or synthetic lubricant, which is prepared by adding many additives such as antioxidant, antiseptic, detergent and dispersant, antifriction agent and so on.

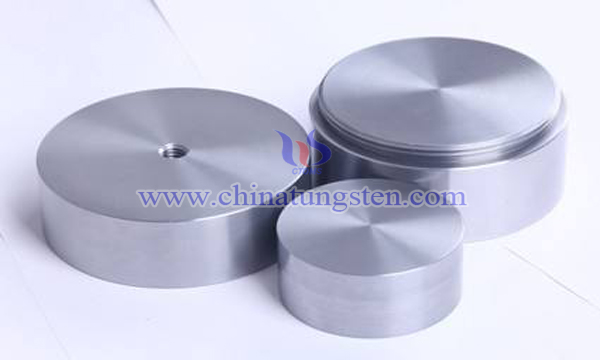

Tungsten Molybdenum Alloy Sputtering Targets

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:07

Tungsten molybdenum alloys can be used at higher temperatures than molybdenum or molybdenum alloys. Molybdenum-tungsten alloy has better conductivity, oxidation resistance and lower coating stress than molybdenum, which meets the requirement of sputtering target material for flat display film production line. Especially the Mo-W alloy with tungsten content of 3.5%25% is more suitable for high quality flat panel display.

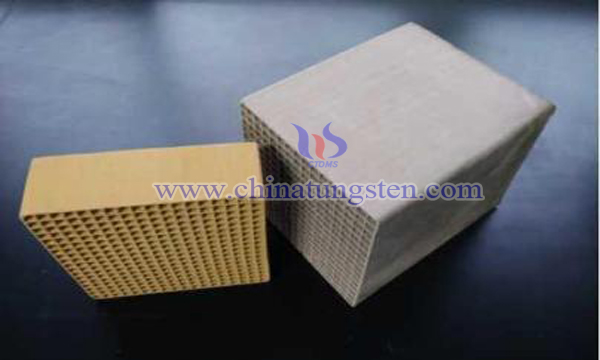

Cerium Tungsten Tantalum Catalyst for Denitrification

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:03

In recent years, selective catalytic reduction (SCR) has been widely used as the most efficient denitrification technology at present. The principle of this air pollution control technology is that in the presence of reducing agent NH3, the flue gas containing NOx reacts with the surface of the catalyst in a certain temperature range through the catalyst, making NOx react with the surface of the catalyst. The NH3 reaction is converted into harmless N2 and H2.

sales@chinatungsten.com

sales@chinatungsten.com