Cerium Tungsten Tantalum Catalyst for Denitrification

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:03

In recent years, selective catalytic reduction (SCR) has been widely used as the most efficient denitrification technology at present. The principle of this air pollution control technology is that in the presence of reducing agent NH3, the flue gas containing NOx reacts with the surface of the catalyst in a certain temperature range through the catalyst, making NOx react with the surface of the catalyst. The NH3 reaction is converted into harmless N2 and H2.

To this end, some researchers have proposed a vanadium-free SCR denitrification catalyst, cerium tungsten tantalum denitrification catalyst. The synthesis scheme includes:

1)First, cerium and tungsten are mixed and dissolved in water for 6 hours, then tantalum is added and then placed for 10 hours to obtain the mixed solution.

2)Adjust the pH of the mixed solution with urea solution (step 1) so that the pH of the solution reaches 9; heat and stir; heating temperature is 50 ℃, stirring time is 12 hours.

3)The mixed liquid obtained in step 2 is filtered to obtain the sludge; the filtered sludge is dried at 120 ℃ for 8 hours to obtain the lump; the lump obtained after drying is ground to obtain the powder, which is the active component.

4)The obtained active ingredients were mixed with carrier powder, additives and water and stirred evenly to obtain pasty sludge.

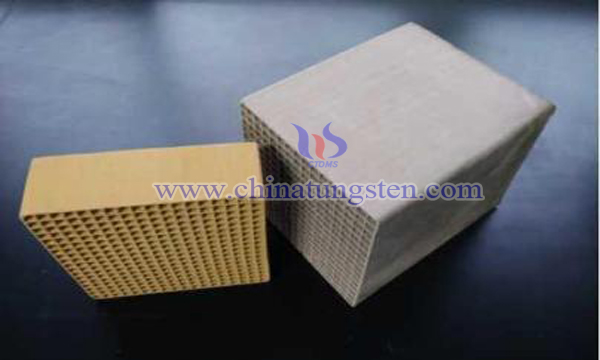

5)The paste mud obtained in step 4 is extruded and the forming catalyst is a honeycomb cylinder to obtain the forming catalyst.

6)The formed catalyst was dried to obtain the dried formed catalyst.

7)The dried catalyst was calcined under the condition of calcining at 300 ℃ for 8 hours, and the final product of cerium tungsten tantalum denitrification catalyst was obtained.

Among the three cerium-tungsten-tantalum materials, tungsten is a good solid acid modifier. Because of its good activity and stability, tungsten has the potential to replace vanadium in the field of flue gas denitrification with high temperature fixed source. Cerium, as a light rare earth element with high content, has relatively low price, and has the condition of large-scale application, CeO2 has good performance. Oxygen migration and storage and release properties, therefore, CeO2 can be used for selective catalytic reduction of NO2. Tantalum is a chemical element with stable properties. Ta oxide is a solid acid oxide with good catalytic performance. At the same time, the properties of Ta oxide are relatively stable. The combination not only has no toxic effect of vanadium, but also has high catalytic activity and good sulfur resistance.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com