Tungsten Diselenide Nano-sheet Speed Up The Quantum Computing

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 June 2019 13:24

Current operating computers and electronics are based on motion and energy states, with an operating speed of approximately 1 billion operations per second. Typically, the rate at which these devices apply voltage depends on the number of transistors. The smaller the switch, the higher the clock frequency and the higher the performance of the computing system. But do you know that in the future, quantum computing will increase the existing limit speed by another 1 million times and achieve 1000 trillion operations per second.

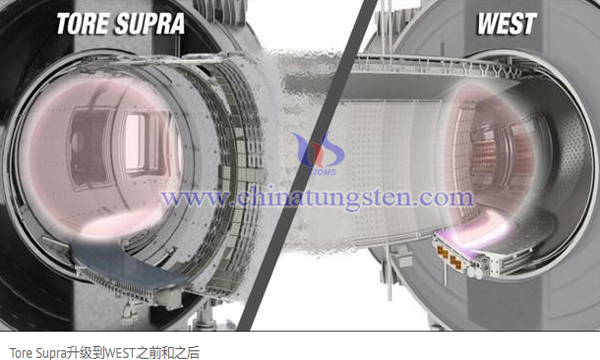

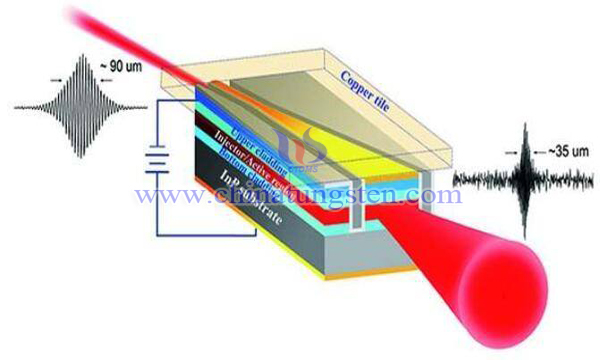

Tungsten-Based Materials Applied in French West Tokamak Project

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 June 2019 13:03

Recently, a team of scientists at the US Department of Energy's Princeton Plasma Physics Laboratory won the US Department of Energy Science Award, which resulted in the development of two new X-ray diagnostic instruments for the French West Tokamak project. This instrument can be used to diagnose the possible risk of melting of the first wall material of the plasma in the ITER artificial solar project.

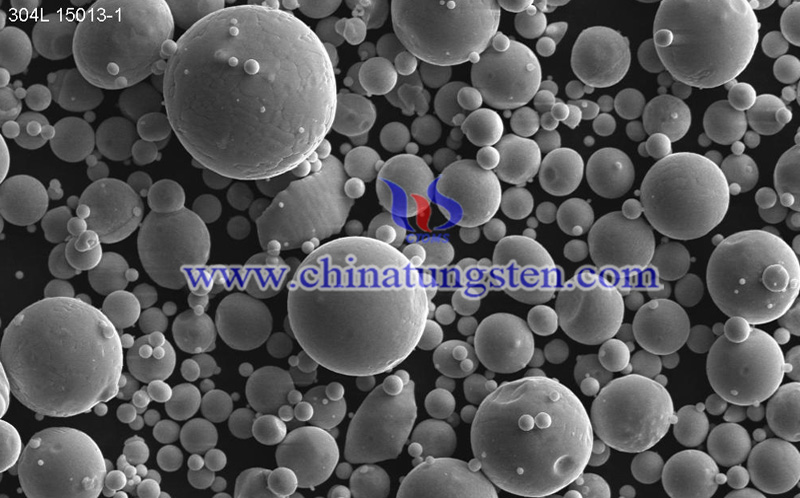

Spherical Tungsten Carbide Powder Property and Application

- Details

- Category: Tungsten Information

- Published on Tuesday, 18 June 2019 17:51

Spherical tungsten carbide powder has the microstructure of fine equiaxed dendrites, its morphology of dense homogeneous spherical WC particles. It maintains a stable chemical property, good fluxibility and hardness, and outstanding wear or abrasion resistance.

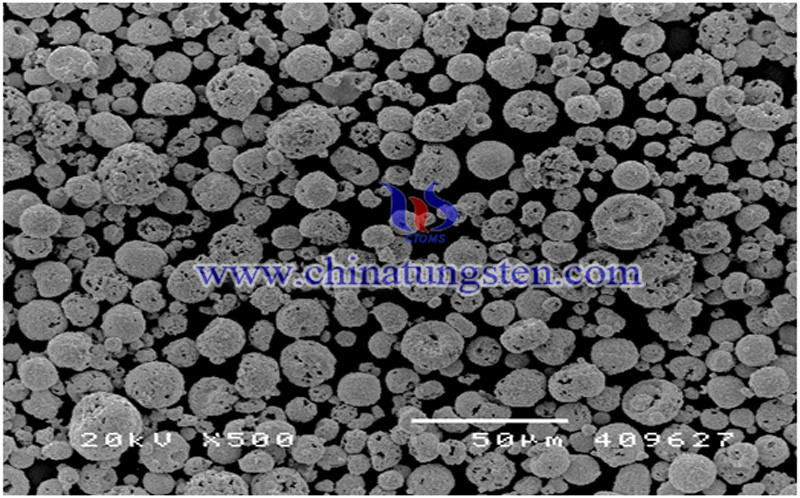

Spherical Tungsten Powder Production Methods - 2/2

- Details

- Category: Tungsten Information

- Published on Monday, 17 June 2019 15:13

Many spherical tungsten powder manufacture methods have been researched and developed by advanced technologies to comply with the more strictly usage requirements in different industries. Below are another two tungsten-hydrogen halide reduction methods.

Spherical Tungsten Powder Production Methods - 1/2

- Details

- Category: Tungsten Information

- Published on Monday, 17 June 2019 15:00

Spherical tungsten powder’s particle size for producing cemented carbide has been changing smaller of the past 20 years. As the fine-grained cemented carbide tungsten powder can significantly improve the hardness and strength of the alloy.

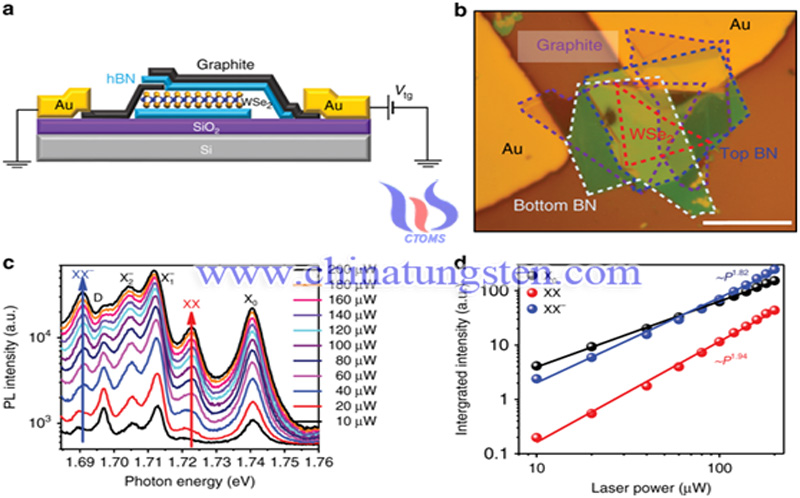

0.7nm Tungsten Selenide (WSe2) Been Developed

- Details

- Category: Tungsten Information

- Published on Monday, 17 June 2019 14:50

0.7nm tungsten diselenide (WSe2) diode has been successfully developed by Dr. Lin’s team from integrated Synchrotron Radiation Research Center of Taiwan Hanyu energy technology company, it’s meaningful of our humans have finally broken the semiconductor 3nm process limit, surpassing Moore's Law and directly entering the sub-nano era (<1 nm). It also reveals that the era of compound semiconductors will eventually replace silicon semiconductors.

Preparation Method of Nanocrystalline Reinforced Tungsten Oxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Friday, 14 June 2019 01:20

Tungsten oxide electrochromic film has great application value in the field of building energy-saving glass due to its real-time adjustment of indoor lighting and thermal insulation. It is considered as the next generation energy-saving window material to take over Low-e coated glass.

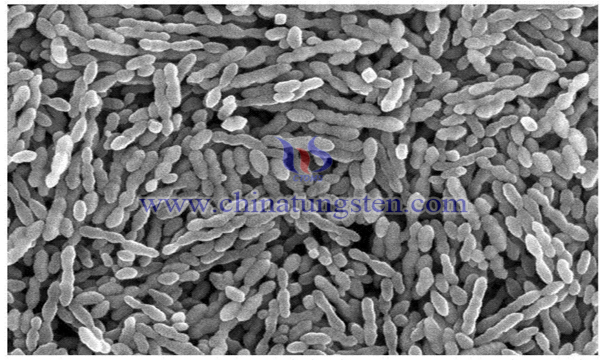

Preparation Method of Monoclinic Phase Cobalt Tungstate Nanorod Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 13 June 2019 13:19

Cobalt tungstate (CoWO4) is one of the representatives in the series of divalent transition metal tungstates. The crystal itself is a typical wolframite ore P2/c monoclinic space group structure. Due to its special structure, CoWO4 crystal exhibits a high dielectric constant, making it an important role in catalytic decomposition of organic pollutants, photoelectric displays, microwave dielectric ceramics, photovoltaic electrochemical cells, and magnetic memory material.

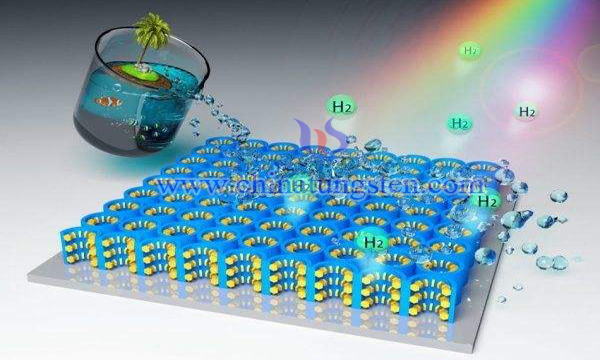

How To Prepare Titanium-Tungsten Binary Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 13 June 2019 13:04

As a new type of wastewater treatment technology, photocatalysis has attracted the attention of researchers with its remarkable advantages of completely mineralizing organic pollutants. Photocatalyst is also widely used in the building decoration market and indoor vehicles. The photocatalytic process has almost no limitation for the degradation of organic matter, can completely mineralize organic pollutants, no secondary pollution, simple equipment, low investment, good effect, etc. advantage.

A Nano Titanium Oxide-Zirconia Tungsten Powder With High Infrared Radiation Performance

- Details

- Category: Tungsten Information

- Published on Sunday, 09 June 2019 16:29

The composite material prepared by the composite powder obtained by uniformly doping the metal-based particles with the nano ceramic powder not only has excellent toughness, thermal conductivity and the like of the metal, but also has high temperature resistance, wear resistance and corrosion resistance of the ceramic, and high hardness and highness. Chemical stability and other characteristics.

sales@chinatungsten.com

sales@chinatungsten.com