Nano Single Layer Tungsten Disulfide Reinforced Carbon Fiber Sizing Agent

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:41

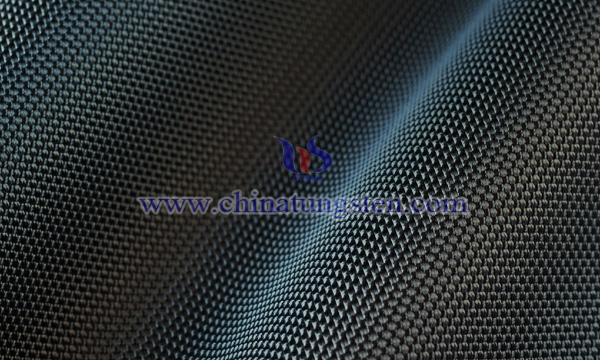

Carbon fiber is known as a new inorganic material. It has a series of excellent properties such as high specific strength, high specific modulus, high temperature resistance, corrosion resistance, fatigue resistance, radiation resistance, conductivity, heat transfer, shock absorption and noise reduction. As a typical high performance fiber, carbon fiber is widely used as a reinforcing fiber of advanced resin matrix composites. At present, its application field is mainly in aviation and aerospace. It can greatly reduce the weight of prefabricated parts and further improve the technical performance.

Aluminum-Based Tungsten Boride Composites

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:37

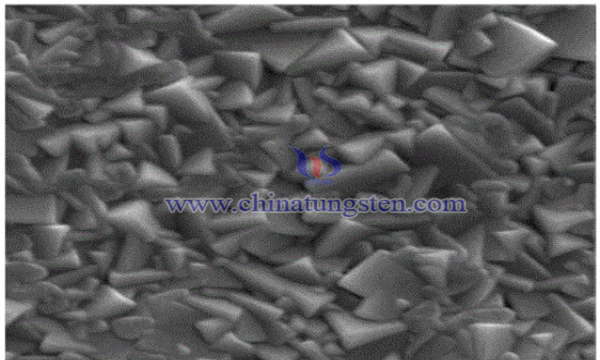

There are a large number of X, gamma rays and neutrons in the radiation field environment of nuclear power plants and nuclear power plants. In order to ensure absolute safety, these X, gamma rays and neutrons need high-density radiation shielding materials. At present, the commonly used materials are lead-boron polyethylene, boron-containing polypropylene, cadmium plate, boron steel, tungsten-based heavy alloy, boron carbide and aluminum-based boron carbide. The above materials are only lead-boron polyethylene. Material can shield x, gamma rays and neutrons at the same time. Other materials can only shield one of the x, gamma rays or neutrons.

Tungsten Sulfide Modified Copper Oxide Hydrogen Evolution Photoelectrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 15:20

Photoelectrochemical hydrogen evolution technology is a new energy technology. It combines photoelectric conversion process with hydrogen evolution process. Solar energy can be converted into electric energy. It can be further used to prepare hydrogen from electrolytic water by hydrogen evolution catalyst. It has great development potential.

Hydrothermal Method to Prepare Tungsten-copper Composite Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 13:04

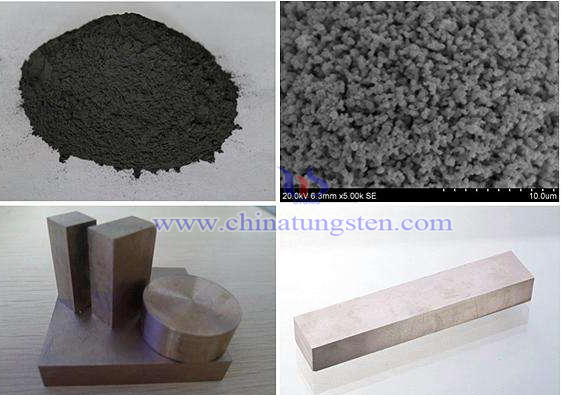

Tungsten-copper composite material is a pseudo-alloy composed of tungsten (high melting point, high hardness ) and copper (high conductivity and thermal conductivity). It is an excellent material to be applied in electrical contacts and electrodes. The combination of low-expansion-coefficient tungsten and high-conductivity copper can be applied to heat sink substrates of airtight packaging such as CPU, IC, solid state microwave tube, radio communication device. It is also used in ultra high voltage electrical contact materials and nozzles. Throat liner, electron beam target and plasma-oriented divertor material.

Environmental Inspections in JiangXi, China Continue to Rise Global APT Price

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 12:43

Last week, the price of ammonium terephthalate (APT) in Europe and the Chinese export market continued to rise, mainly because Jiangxi Province, the world's leading tungsten production center, is undergoing environmental inspections. In addition, due to the unilateral withdrawal of the United States from the Iranian nuclear agreement, the relevant countries in the Middle East are preparing for war, which has also provoked panic in the global buyer market. Therefore, most people will express their concerns about the future supply of tungsten.

Preparation of Supercapacitor Electrode by Tungsten Disulfide-carbon Aerogel Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 00:50

Supercapacitors are new energy storage devices between traditional capacitors and secondary batteries that have developed rapidly in recent years. They have the advantages of both - higher energy density than conventional capacitors, and more than two The higher power density of the secondary battery has made it a widespread concern in the field of new energy vehicles.

Synthesis of Vanadium-free Titanium-tungsten Powder as SCR Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 00:30

As energy consumption increases, a large amount of fossil fuels are consumed, resulting in an increase in the emission of nitrogen oxides, causing great damage to the environment. Therefore, NOx emission control under oxygen-rich conditions has become a research hotspot in the field of environmental catalysis and air pollution control technology.

Seven-day Workweek Greatly Improved Drakelands Tungsten Mine’S Production Capacity

- Details

- Category: Tungsten Information

- Published on Tuesday, 04 June 2019 00:07

It is in a period of rapid expansion and production increase in the tungsten mine project in Drakelands, Devon, UK. Up to now, the increase in production capacity and the rise in tungsten prices, have provided strong support for the stock price of developer Wolf Minerals.

Tungsten-containing Compounds Coated Cathode Materials for Lithium-ion Batteries

- Details

- Category: Tungsten Information

- Published on Monday, 03 June 2019 22:45

With the progress of science and technology, various high-end equipment in the field of national defense and military put forward higher requirements for lithium-ion batteries. It is of great practical significance to seek high-performance lithium-ion batteries. Among them, the performance of cathode materials has become the key factor to limit the further improvement of lithium-ion battery performance. It is very important to find high-performance cathode materials for lithium-ion batteries.

Hydrogen Evolution from Nano Tungsten Oxide Application

- Details

- Category: Tungsten Information

- Published on Monday, 03 June 2019 22:35

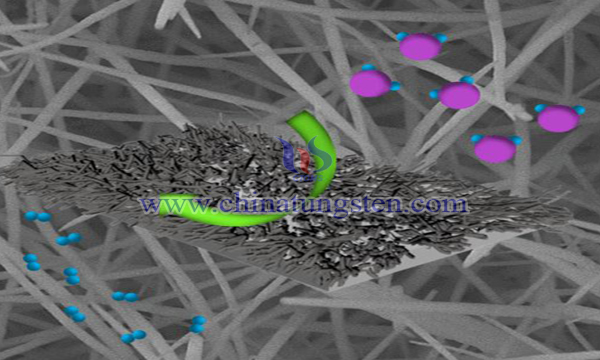

Among many energy sources, hydrogen is a clean and recyclable material, which is considered to be an ideal energy carrier. Electrolyzed water hydrogen production is one of the most promising and clean hydrogen production methods. Traditionally, it can effectively reduce hydrogen evolution. The electrode materials of the potential are mainly platinum-based precious metals, but the reserves of these metal materials on the earth are scarce and expensive, and large-scale promotion cannot be achieved. Therefore, the development and research of a hydrogen evolution electrode with high catalytic activity and low cost is of great theoretical and practical value.

sales@chinatungsten.com

sales@chinatungsten.com