Heteropoly Acid Preparation from Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 27 July 2018 09:27

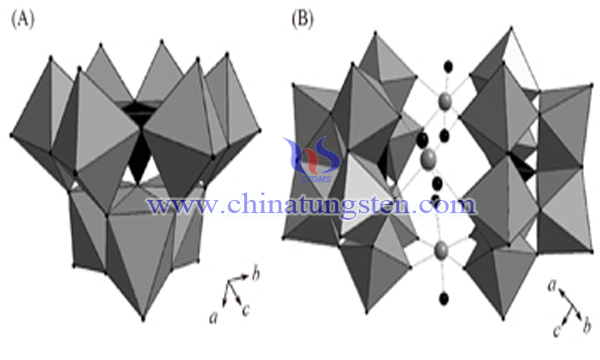

Heteropoly acid is a kind of acid, which has been acidified, condensed and dehydrated by two or more than two kinds of inorganic oxyacid ions. It is a new type of acid catalyst and oxidation-reduction catalyst, which has been widely studied and developed in recent years.

With high heteropoly acid and stable structure, it is easy to dissolve in water and oxygen containing organic solvents. It is an excellent acid catalyst. It has advantages of superior catalytic performance, non volatilization, small corrosion, easy reaction and so on. It has been used in the hydration of propylene, butylene and isobutene to prepare alcohols, acetic acid and ethylene to synthesize ethyl acetate directly. The process of selective polymerization of tetrahydrofuran to produce poly (tetramethylene ether glycol) and methacrylic acid oxidation to methacrylic acid.

Heteropoly tungstate is usually prepared from sodium tungstate as a raw material. The most commonly used method is to convert sodium tungstate into sodium salt containing tungstic heteropoly acid. However, the commonly used methods also have its shortcomings, which are characterized by a large amount of acid consumption, and a large amount of ether with low boiling point. The safety is poor, and a small amount of sodium ions are easily retained in the product. These sodium ions will affect the performance of heteropoly acid.

Some experts have proposed a method of preparing tungstic heteropoly acid with tungsten. Tungsten powder is used as raw material to convert tungsten into tungstic acid with hydrogen peroxide, and then reducing peroxy tungstic acid to tungstic acid by reducing agent. The tungstic acid can be precipitated with different oxygen containing acid, and the needed tungsten heteropoly acid can be prepared respectively. The specific implementation is as follows:

The 2g high purity tungsten powder, 10 microns in diameter, was put in three glass bottles and added with 5g distilled water to moisten it. Under constant stirring conditions, 30 weight% hydrogen peroxide 10.65g (1.6 times the weight of tungsten powder) was added, the control temperature was 20°C. After adding the hydrogen peroxide, continue stirring until the tungsten powder is completely dissolved. The solution was heated to 40°C, kept in the SO22.4g (the molar ratio of H2O2 to 0.4), which completely precipitated tungstic acid. Then, under constant stirring conditions, the tungstic acid was precipitated in batch and added to the 5.5mL 0.5mol/L phosphoric acid (13.5% of the weight of tungsten powder in H3PO4), and the temperature was 60°C. Phosphotungstic acid can be obtained by heating evaporation crystallization after completely dissolving the tungstic acid precipitates. The yield of tungsten is 96.2%.

The advantages of tungsten bearing heteropoly acid by tungsten are: (1) The product has high purity and no other cationic impurities. (2) The process is simple and the production cost is reduced. (3) The yield of phosphotungstic acid is not less than 95%, the yield of silicotungstic acid is not less than 85%. (4) The production process does not use a large number of high concentration of strong acid, the corrosion of the equipment. The corrosion was significantly reduced. (5) The safety of production operation was obviously improved without using flammable low boiling point organic extractant.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com