A-10 Thunderbolt II Attack Plane Uses Tungsten Alloy Bullets

- Details

- Category: Tungsten Information

- Published on Friday, 07 June 2019 18:24

A-10 Thunderbolt II is a single-seat twin-engine attack aircraft made by US which provides a support for ground forces, including attacking enemy tanks, armored vehicles, armed vehicles, and important ground targets.

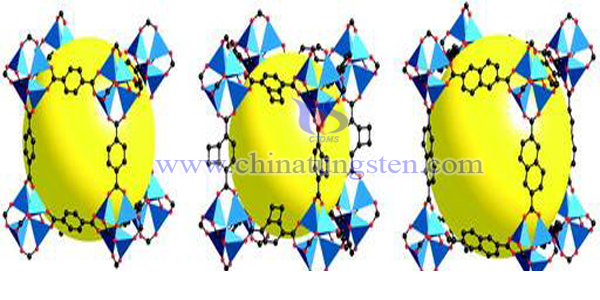

Phosphotungstic Acid-Organometallic Framework Catalytic Material

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 15:48

Biomass can be regarded as a promising alternative energy source for petroleum. The key to convert biomass into important energy materials and basic platform compounds is to convert cellulose, an important component of biomass, into glucose by directional hydrolysis.

Tungstate Red Phosphor

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 15:44

Tungstate red phosphor white LED is a new type of solid-state lighting electric light source (SSL). Its principle and structure are different from those of previous vacuum electric light sources such as incandescent lamp and fluorescent lamp. SSL light source has many advantages, especially high light efficiency, energy saving, long life and pollution-free. It has great application value and prospects.

New Preparation Process of Tungsten Carbide-Titanium Carbide Solid Solution

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 15:38

The new preparation process of tungsten carbide-titanium carbide solid solution tungsten carbide-titanium carbide solid solution is a kind of compound carbide with high melting point, high hardness, high wear resistance, excellent anti-adhesion, oxidation resistance and wear resistance. It is widely used in cemented carbide products for mechanical processing. It is found that when carbide mixtures are added, it is difficult to control the carbon content because of the solid solution reaction during the sintering process. Therefore, carbide solid solution is usually added to cemented carbides in the production of cemented carbides.

SCR Catalyst Recovery Process Improvement

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 15:16

SCR catalyst belongs to hazardous solid waste, which will seriously pollute the environment. Meanwhile, various valuable metals contained in the failed catalyst have not been recycled, resulting in a huge waste of resources. Therefore, the recycling of failed catalysts can not only solve the corresponding risk of environmental pollution, but also turn waste into treasure and make full use of resources.

Titanium-Tungsten Alloy by Molten Salt Electrolysis

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 15:12

Titanium-tungsten alloy has been widely used in microelectronics and biomedicine because of their excellent properties. The alloys formed by adding W to Ti have higher strength and hardness, and the ductility loss is very small. The non-magnetic W solid solution in Ti matrix can reduce the elastic modulus of Ti and increase its radiation resistance. In the field of electronic information, with the development of semiconductor VLSI industry, the elastic modulus of Ti can be reduced. With the development of titanium-tungsten alloy, high purity titanium-tungsten alloys can be used in electrode materials, diffusion barrier layers and wiring materials in the form of thin films.

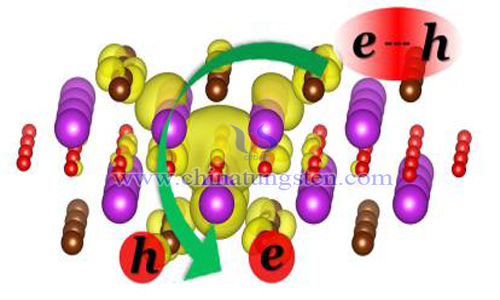

Silver Tungstate Photocatalyst Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 10:34

When a semiconductor irradiates light with energy above bandgap, the electrons of valence band excite in the conduction band, generate holes in the valence band, and generate electrons in the conduction band. They have strong oxidation and reduction abilities respectively, and have redox effects on molecular species in contact with semiconductors. Such an action is called photocatalysis, and such semiconductors are called photocatalysts.

How to Extract Cobalt and Tungsten from Waste Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 09:57

With the rapid development of economy, the demand for tungsten and cobalt in machinery manufacturing, geology, mining, construction, electronics and chemical industries is increasing. As rare metal elements, tungsten and cobalt are also the main raw materials of cemented carbide. Therefore, it is very meaningful to recycle tungsten and cobalt from scrap cemented carbide.

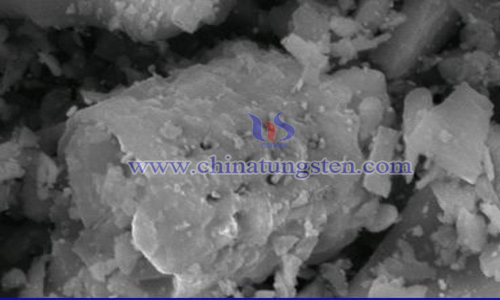

Bismuth Tungstate Powder Photocatalyst Preparation by Microwave Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 09:46

In the study of photocatalysis of bismuth tungstate, scholars believe that morphology control has always been a research hotspot in nanomaterials. As the simplest layered Aurivillius oxide, Bi2WO6 has a layered structure, which is most conducive to the formation of two-dimensional structure. The reaction conditions of synthesis can be controlled to obtain complex multi-level structure, so as to improve its photocatalytic performance. Therefore, a new preparation method upgraded to hydrothermal synthesis came into being, which is called microwave hydrothermal method.

Preparation of Phosphotungstic Acid Ionic Liquid Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 06 June 2019 00:51

With the shortage of fossil energy, rising oil prices and increasing environmental pollution caused by vehicle emissions, there is an urgent need to find new alternative energy sources. Among them, biodiesel has attracted people's attention because of its renewability and low emission.

sales@chinatungsten.com

sales@chinatungsten.com