How To Prepare Titanium-Tungsten Binary Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 13 June 2019 13:04

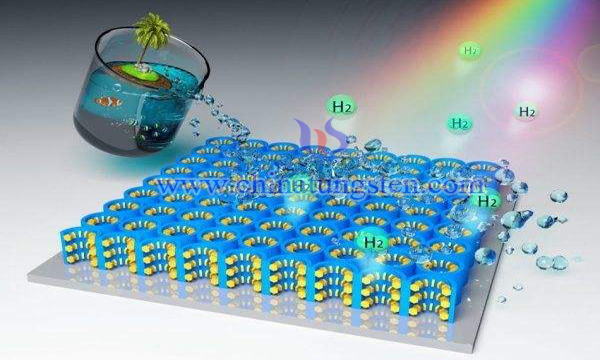

As a new type of wastewater treatment technology, photocatalysis has attracted the attention of researchers with its remarkable advantages of completely mineralizing organic pollutants. Photocatalyst is also widely used in the building decoration market and indoor vehicles. The photocatalytic process has almost no limitation for the degradation of organic matter, can completely mineralize organic pollutants, no secondary pollution, simple equipment, low investment, good effect, etc. advantage.

The traditional photocatalytic oxidation technology uses titanium dioxide (TiO2) as a catalyst. Tio2 is inexpensive, and the only drawback is that the band gap is wide (about 3.2 ev). The high-energy ultraviolet light is required to excite the electrons in the valence band. In the natural world, the ultraviolet radiation content in sunlight is low, only 5% of the total illumination of sunlight, and the utilization of sunlight is low, which limits the application of the technology in practice.

It has been found that tungsten catalysts have good catalytic properties, and tungdten trioxide (WO3) is favored for its low cost and easy availability. WO3 has a narrow band gap (2.4eV-2.8eV), which can fully utilize visible light, but its redox ability is weak, so the researchers believe that the optical response range and photocatalytic performance can be further improved by changing the WO3 structure and loading other metals. For example, titanium dioxide is combined with tungsten trioxide to form a titanium-tungsten binary composite photocatalyst.

The preparation process of the titanium-tungsten binary composite photocatalyst includes the following steps:

Step 1. Weigh 30 g of the inorganic titanium compound TiBr4 with an electronic specific gravity scale, and dissolve it in a 100 ml beaker with water.

Step 2. Vacuuming the bottom side of the filter medium with a vacuum filter at a vacuum pressure of 60 kPa to form a uniform titanium compound solution.

Step 3. Add 50ml of 10% CO(NH2)2 solution and add slowly at a rate of 1 drop/second. At this time, uniform precipitation will gradually appear. After the precipitate is uniformly precipitated, it is transferred to a three-neck bottle and heated and stirred for 30 minutes. When the temperature reaches 60 ° C, slowly add distilled water, add 10 ml of a mass concentration of 5% glycolic acid, and form a competitive reaction with anions, metal particles and organic acids in the solution to form a surface on the metal particles and non-metal particles of the inorganic nano layer. The layer was modified to obtain a surface-modified inorganic nanosol, and a mixture of 10 ml of an inhibitor of absolute ethanol and cyclohexane was added to form a turbid colloidal solution.

Step 4, adding 20 ml of ammonium dihydrogen phosphate with a mass fraction of 15%, 20 g of ammonium phosphotungstate (tungsten source), 10 ml of nitric acid with a mass fraction of 20%, and dropping the liquid material at a rate of 2 ml/s. Into a three-neck bottle.

Step 5. After the completion of the titration, the mixture was stirred at a high speed, and the stirring speed was continued without generating bubbles and splashing. The stirring time was 1 h, and the mixed liquid was transferred to a tetrafluoroethylene reactor.

Step 6. Photoelectrocatalytic treatment: Transfer the mixed liquid in the tetrafluoroethylene reactor to the prepared electrochemical reaction electromagnetic, the catalytic time is 30 min, and the light intensity is 50 w ultraviolet lamp.

Step 7. Modification was carried out by adding 5 g of a strong oxidizing agent chloric acid to the tetrafluoroethylene reactor.

Step 8. Add CO(NH2)2 and absolute ethanol to the tetrafluoroethylene reactor to continue precipitation to form a white transparent colloid. For example, 50 ml of a 10% CO(NH 2 ) 2 solution and 20 ml of absolute ethanol are added.

Step 9. The obtained white colloidal solution was refluxed twice, wherein the first reflux time was 30 min, the reflux temperature was 50 ° C, the second reflux time was 1.5 h, the reflux temperature was 80 ° C, and finally centrifugation (ultrasound) Centrifugation, time 12h), drying, and finally form a titanium-tungsten composite photocatalyst.

The above process adds a tungsten source to form a titanium-tungsten binary composite photocatalyst, which reduces the forbidden band width. It also improves the particle structure by means of photosensitization, photoelectrocatalysis or chemical modification, forms micro-mesoporous particles, improves the surface state of the particles, and enhances the surface-capture efficiency of photons.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com