Foam Metal Tungsten Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2019 10:57

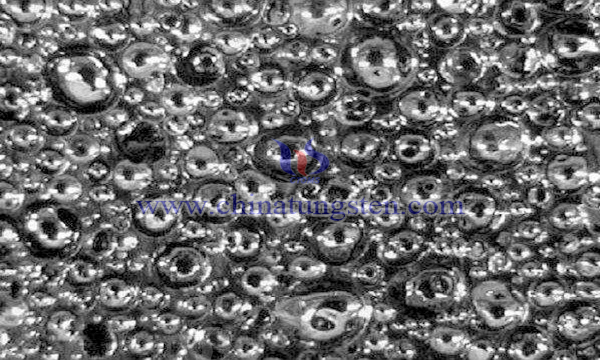

Foamed metal tungsten is a kind of material with double properties of function and structure. It has certain strength, high temperature resistance and corrosion resistance, and has low density, high porosity and large surface area. It is widely used in modern defense and military, atomic energy, aeronautical and aerospace, electronic information and other fields.

An Effective Separation Process for Tungsten-Molybdenum Associated Ore

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2019 01:11

Molybdenum and tungsten resources are China's dominant resource minerals. China's reserves of molybdenum and tungsten resources, mining and processing volume, and trade volume occupy an important position in the world, while tungsten is in the first place. Tungsten mainly exists in the form of black tungsten and scheelite. The scheelite often contains a certain amount of molybdenum, which is usually in the form of molybdenum sulfide, which can be separated by conventional flotation methods. The tungsten resource containing molybdenum oxide is difficult to process. It is rarely used.

A New Effective Mineral Processing Method for Scheelite-Fluorite Associated Ore

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2019 00:43

China's reserve of scheelite-fluorite associated ore is in enormous quantity. This type of ore presents in fine-grained inlays, complex ore composition, and symbiotic with a variety of minerals such as sulfide ore and calcite. calcium-bearing mineral scheelite-fluorite-calcite has a difficulty in flotation, the traditional scheelite flotation process is not good for subsequent fluorite flotation, and the fluorite extraction rate is not high.

A New Mineral Processing Method to Tungsten-Tin Ore

- Details

- Category: Tungsten Information

- Published on Sunday, 26 May 2019 20:17

Tungsten-tin ore is brittle and easy to over-grind during the grinding process, which causes some tungsten-tin ore to be muddy during the grinding process. It is difficult to re-elect the fine-grained tungsten-tin ore. At the same time, both black tungsten ore and cassiterite are minerals that are difficult to float, which are more demanding on flotation reagents and flotation conditions. The flotation process recovers tungsten tin ore flotation reagents, which consumes a lot of money and has high production costs and not suitable for flotation.

A Greener Method to Extract APT

- Details

- Category: Tungsten Information

- Published on Sunday, 26 May 2019 19:24

Ammonium paratungstate (APT) is an important intermediate in tungsten metallurgy and tungsten chemicals. The common material to prepare APT is a crude sodium tungstate solution obtained by treating a tungsten raw material (including a mineral raw material and a secondary raw material). The crude solution mainly contains sodium tungstate Na2WO4, and impurities such as NaOH, P, As, Si, Sn and so on.

Tungsten Trioxide-Carbon Nitride-Bismuth Oxide-Double Z Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 22:17

In recent years, with the deep research on semiconductor heterojunction and Z-type mechanism, in order to solve the problem of carbon nitride, scientists usually use other semiconductor materials to form a heterojunction with carbon nitride, for example: carbon nitride / trioxide The tungsten binary heterojunction can expand the spectral range of light absorption by constructing a hybrid system, suppress the recombination of photoelectrons and holes, and obtain higher redox performance.

Single Layer Nano Tungsten Disulfide Solar Cells Application

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 22:10

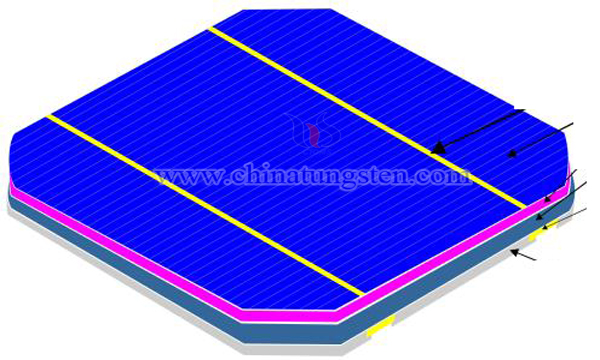

With the sharp rise in oil prices and the depletion of mineral resources, solar energy has attracted more and more attention due to its inexhaustible, unrestricted geographical and clean and safe advantages. Solar cells based on photovoltaic effect to convert solar energy into electricity are one of the main ways to utilize solar energy.

Rare Earth Modified Tungsten-based Ultra-thin Diamond Saw Blade

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 22:03

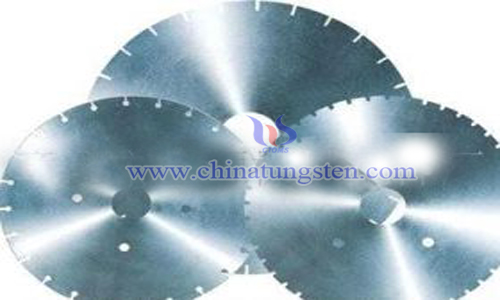

Ultra-thin diamond saw blade refers to the diamond saw blade with a thickness of less than 1.0 mm and high precision. Its cutting tool slot is narrow, which is beneficial to saving valuable materials in the cutting process. It is widely used in cutting silicon, silicon carbide and other photoelectric materials.

Tin Dioxide--Bismuth Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 21:52

In recent years, semiconductor photocatalysis has become one of the research hotspots in the field of environment. A large number of studies have shown that almost all organic pollutants can be effectively photocatalytically degraded, decolorized and mineralized into inorganic small molecular substances, thereby eliminating environmental pollution and hazards.

Flotation Process Improvement at Room Temperature

- Details

- Category: Tungsten Information

- Published on Saturday, 25 May 2019 21:46

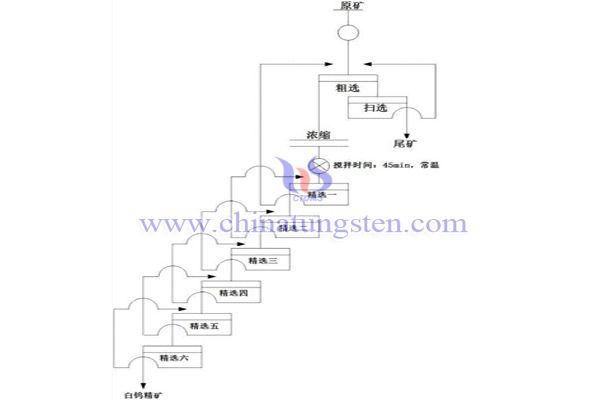

China's tungsten reserves rank first in the world, two-thirds of which are scheelite. However, scheelite is often distributed in fine grains, the grade of raw ore is low, and it often coexists with calcareous gangue minerals with better floatability. Therefore, the separation of scheelite and calcareous gangue minerals has always been a difficult problem in the mineral processing industry.

sales@chinatungsten.com

sales@chinatungsten.com