ITER First Wall Protective Coating Material

- Details

- Category: Tungsten Information

- Published on Friday, 29 June 2018 22:02

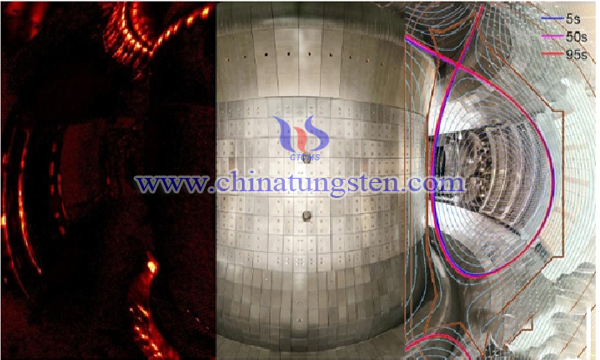

Pure tungsten material not only has the common properties of general metals, such as conductivity, thermal conductivity, plasticity and metallic luster, but also has high density, high melting point, high thermal conductivity, low vapor pressure, low thermal expansion coefficient, strong absorption ray ability and sputtering threshold, good corrosion resistance and so on. Therefore, the ITER nuclear polymerization is very good. For variable device parts, it is an important material for plasma first wall protective coating.

Due to the larger thermal expansion property between pure tungsten and copper and copper alloys, the strength of copper alloy (chromium zirconium copper) is higher than that of copper, and it is not easy to form deformation. No matter in the process of CVD (chemical vapor deposition) deposition or in the service of components, large thermal stress will be produced, which will lead to the disintegration of the copper alloy /CVD- tungsten coating interface, which can not be effectively connected to the use of the components.

There are many researches on the preparation technology of pure tungsten coating at home and abroad, such as molten salt plating, plasma spraying and chemical vapor deposition (CVD). Chemical vapor deposition (CVD) is one of the most widely applicable processes at present. It can directly obtain high purity, high density structure and one of the pure tungsten coating methods, which are not restricted by the shape of the workpiece. The main process is as follows:

(1) Using chromium zirconium copper (CuCrZr) alloy with a thickness of 40mm as a base material, 3 layers of tungsten copper functionally graded materials (60%, 30% and 10% respectively, corresponding to W60Cu, W30Cu and W10Cu respectively) were prepared by the cold isostatic pressure sintering process of thickness 1mm respectively, which correspond to W60Cu, W30Cu and W10Cu as the sustained release layer of copper stress.

(2) The copper 60% side of 3 layers of tungsten copper functionally graded materials and chromium zirconium copper alloy base material are at the temperature of 450 to 950 °C, the pressure is 5 ~ 90MPa, and the vacuum degree is not less than 10-1Pa, and the time is 1H. In order to ensure that chromium zirconium copper alloy does not precipitate solid solution, the temperature in welding should be controlled below 600°C.

(3) The oxide layer containing the copper 10% of the 3 layer tungsten copper functionally graded material is removed and cleaned by dilute hydrochloric acid (0.05mol/L hydrochloric acid solution, 15 minutes) and pure water. The samples after cleaning are obtained.

(4) The cleaned sample is put into the deposition furnace and heated under the hydrogen atmosphere. The surface temperature of the base material reaches a preset deposition temperature of 580°C and is stable. The mixed gas of six tungsten fluoride and hydrogen with the purity of 99.99% is passed into the deposition furnace by the ventilation port of the deposition furnace, and six of the tungsten fluoride flow is 0.1mol/min (the temperature is higher than 45°C, and the pressure is 70-120kPa), the flow rate of hydrogen is 0. .2mol/min, a mixture of six tungsten fluoride and hydrogen gas is passed into the furnace, and the mixture gas reacts on the surface and near the plate to form tungsten and hydrofluoric acid. The time of deposition is about 1.5h. Tungsten is deposited on the surface of the sheet to form a coating, and the hydrofluoric acid and unreacted gas are discharged from the deposition furnace.

(5) After the reaction was completed, six tungsten fluoride was closed and the heating was stopped. The temperature of hydrogen was continued to fall below 100°C, and the nitrogen was cooled to the room temperature. Then the furnace was dismantled and the samples were removed, that is, the tungsten coated copper alloy components were made. The thickness of tungsten coating (CVD-W) is 1mm, and the deposition rate of tungsten coating is about 0.6mm/h. The surface of the coating is smooth without bulging particles, and the coating has no cracking and peeling.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com