Tungsten Carbide Dispersion Enhanced Tungsten Treatment Process

- Details

- Category: Tungsten Information

- Published on Sunday, 19 May 2019 21:38

Tungsten has many advantages, such as high melting point, high density, high strength, high hardness, low thermal expansion coefficient, excellent corrosion resistance and good processing performance, so it is widely used in aviation, aerospace, electronics, chemical industry, military weapons and other fields.

In order to obtain plasma-oriented materials suitable for use in the field of fusion reactors and other tungsten and its tungsten alloys used in extreme environments, material scientists at home and abroad generally believe that by incorporating dispersed particle phases into tungsten (Y2O3, La2O3, TiC, ZrC, etc. or solid solution strengthening phase (Ti, Ta, Mo, Re, etc.) can significantly improve the high temperature mechanical properties of tungsten and increase the recrystallization temperature of tungsten.

In order to optimize the process of tungsten carbide dispersion strengthening, Chinese scholars have tried in situ synthesis using titanium carbide as dispersion strengthening material. The process includes:

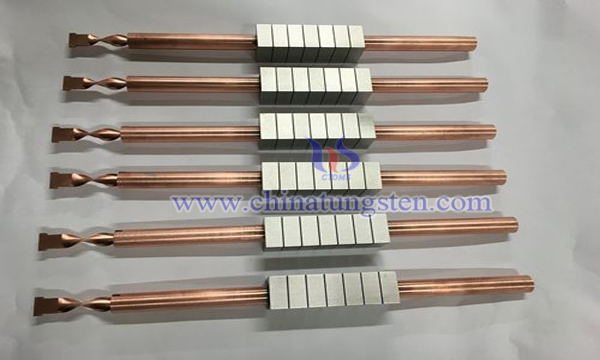

W powder, carbon nanotubes and Ti powder are weighed according to the ratio of 0.3% of carbon nanotubes and 1% of Ti powder. They are put into the WC ball mill tank, and a certain amount of WC ball is added (the ball-to-material ratio is 5:1). The ball mill rotates at 300 r/min for 5 hours. The powders after ball milling are then placed in glove boxes filled with Ar gas, and the powders after ball milling are taken out and filled in graphite moulds with a diameter of 20 mm. The whole operation process was completed in the protective atmosphere of argon (99.99%). Dispersion-strengthened tungsten alloy with rod-like structure was obtained by plasma sintering at 1700 ℃, 50 MPa pressure and 6 Pa vacuum for 1 min. After plasma sintering, the density of tungsten alloy is 99.8%, the Vickers hardness is 564 HV, the bending strength is 1138 MPa, and the grain size is about 0.6 um.

The advantages of in-situ synthesis method are: by adding carbon nanotubes and titanium powder, silicon powder, zirconium powder or tantalum powder into tungsten, titanium powder, silicon powder, zirconium powder or tantalum powder can react with carbon nanotubes in situ to form titanium carbide, silicon carbide, zirconium carbide and tantalum carbide during high temperature sintering.

On the one hand, it can activate the lattice of tungsten, promote the densification of tungsten at lower temperature, and inhibit the grain growth behavior of tungsten at high temperature, so as to obtain fine tungsten, effectively improve the high temperature strength of tungsten, improve the brittleness of tungsten at room temperature. Compared with the similar methods such as hot pressing sintering, the ultra-fine grains prepared by mechanical alloying and spark plasma sintering are better. Tungsten matrix composites have good mechanical properties and electron beam impact resistance. They are suitable for high melting point refractory metal materials in extreme environments, such as plasma-oriented materials in nuclear fusion devices.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com