Cerium-Tungsten Trioxide SCR Denitration Catalyst 2/2

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:35

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Cerium-Tungsten Trioxide SCR Denitration Catalyst 1/2

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:32

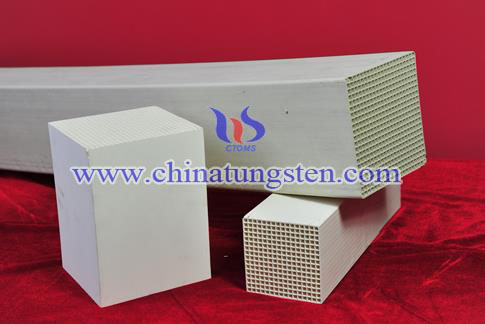

From the precious metal catalyst to today widely used SCR denitration catalyst which is using titanium dioxide as the main catalyst carrier, vanadium pentoxide, tungsten trioxide as main active ingredient, the SCR denitration catalyst has experienced a variety of important technological changes and condensed years of hard work from academics and numbers of plant personnel.

From the precious metal catalyst to today widely used SCR denitration catalyst which is using titanium dioxide as the main catalyst carrier, vanadium pentoxide, tungsten trioxide as main active ingredient, the SCR denitration catalyst has experienced a variety of important technological changes and condensed years of hard work from academics and numbers of plant personnel.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Composite Carrier Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:30

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding Door For X-Ray Room

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:17

Tungsten alloy shielding door for X-ray room is used for X-ray room in hospitals. With the unceasing updating and development of various laboratory examinations, the status of X-ray room at the hospital is rising. X-ray room, as the important auxiliary examining room in the hospital, integrates the inspection, diagnosis, treatment with each other to assist clinical departments in diagnosing many diseases and to make the result of diagnosis more obvious. Equipments in X-ray room generally include ordinary X-ray film, X-ray fluoroscopy, gastrointestinal machine, digital X-ray imaging system, direct digital X-ray imaging system, computer tomography X-ray machines, MRI scanners, digital subtraction angiography system, medical linear accelerators, medical diagnostic X-ray machine, which render the diagnosis and treatment of diseases are more convenient, simple and accurate,.

Tungsten alloy shielding door for X-ray room is used for X-ray room in hospitals. With the unceasing updating and development of various laboratory examinations, the status of X-ray room at the hospital is rising. X-ray room, as the important auxiliary examining room in the hospital, integrates the inspection, diagnosis, treatment with each other to assist clinical departments in diagnosing many diseases and to make the result of diagnosis more obvious. Equipments in X-ray room generally include ordinary X-ray film, X-ray fluoroscopy, gastrointestinal machine, digital X-ray imaging system, direct digital X-ray imaging system, computer tomography X-ray machines, MRI scanners, digital subtraction angiography system, medical linear accelerators, medical diagnostic X-ray machine, which render the diagnosis and treatment of diseases are more convenient, simple and accurate,.

The tasks of X-ray room are to undertake the examination of outpatient, conventional X-ray examination, contrast examination and X-ray computer tomography, magnetic resonance imaging; undertake the radiological examination of health care and rescue and physical examination; carry out consultation inside and outside the hospital and technical inspection required by superior hospital; full use of existing equipment to develop new technologies, new inspection programs; develop new diagnostic imaging technology and technological innovation of equipment; introduce the most advanced technology at home and abroad to cooperate with the clinical departments in some treatment items, such as cerebral angiography, CT hepatic arteriography, bronchial arteriography.

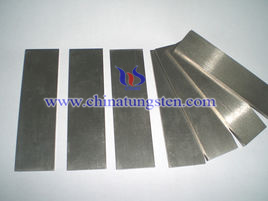

Since radiation used in the X-ray room is harmful, and can cause leukemia, thyroid cancer, bone tumors and other malignant tumors, and also lead to some changes in human genetic material(like gene mutation and chromosomal aberrations), causing congenital distortion, abortion, stillbirth, infertility and other diseases. Tungsten alloy shielding door for X-ray room is used as a radiation shielding barrier for X-ray room in hospitals, to avoid radiation letting out, then protect people around from radiation damage. Compared with traditional materials (such as lead), tungsten alloy shielding door for X-ray room has higher density, and thus in the same weight and the same shielding performance, the tungsten alloy radiation shielding door for X-ray room is thinner.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CsxWO3 Near-Infrared Absorbing Properties

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:15

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding For Killing Pests With Irradiation

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:06

Killing pests with irradiation is a type of physical pest control technology that uses ionization radiation to interact with pests to induce a series of physical, chemical and biological effects, causing sterility and death of pests. The rays used for killing pests are mainlyγ rays(generated by Co-60 or Cs-137) and high-energy electrons(below 10MeV) as well as X rays(below 5MeV) produced by accelerator. Of which cobalt irradiation has developed fast while the development of electron beam and X-ray irradiation are relatively lagging behind. But with the recent development of accelerator technology, electron beam irradiation shows its unique advantages, and has been paid more and more attention. Due to electromagnetic radiation is harmful to human health, normally using tungsten alloy shielding for killing pests with irradiation to protect staffs from the radiation.

Physical pest control method is also called pest irradiation on quarantine, namely uses a variety of electromagnetic radiation (such as microwave, ultraviolet,γ ray, X-ray, ultrasound, infrared, etc.) to irradiate the eggs, larva, pupa, adult, resulting in a series of physiological changes in the body of peats, leading to metabolic disorder, loss of reproductive capacity, and ultimately death. A certain doses of electromagnetic radiation can cause the death and infertility of insect, and shorten its life, delay its eclosion and development, as well as reduce its hatching. Thus, irradiation insecticidal technology is widely used in food industry, animal husbandry and agriculture, for the quarantine treatment of animals and plants and pest control and sterilization in food processing.

Lead is primally used as a shielding material, but there are some problems exist in the long term use of lead shielding. Lead and its compounds can cause human poisoning by entering into human body through respiratory or digestive tract. While compared with lead, tungsten is non-toxic and non-radioactive, so that it will not harm human health. Moreover, the high density of tungsten alloy also makes it thinner and lighter than lead in the situation of the same weight and shielding performance with lead.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Fluorine-18 Tungsten Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 18:02

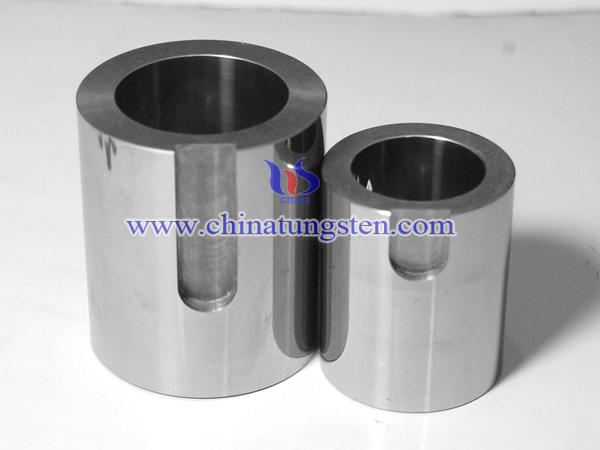

Fluorine-18 tungsten radiation shielding is usually used to shield radiation released when producing and using fluorine-18 and its compounds.Fluorine-18 is a radioisotope of fluorine with half-life of 109.771 minutes that plays an important role in positron source. It decays by positron emission 97% of the time and electron capture 3% of the time. Both forms of decay yield stable oxygen-18. Fluorine-18 is primarily synthesized into fluorodeoxyglucose to use in the radiopharmaceutical industry. It can be used as a tracer in positron emission tomography scan. Use of this tracer to detect the possibility of cancer metastasis is the most frequent type of PET scan in standard medical care.

Fluorine-18 tungsten radiation shielding is usually used to shield radiation released when producing and using fluorine-18 and its compounds.Fluorine-18 is a radioisotope of fluorine with half-life of 109.771 minutes that plays an important role in positron source. It decays by positron emission 97% of the time and electron capture 3% of the time. Both forms of decay yield stable oxygen-18. Fluorine-18 is primarily synthesized into fluorodeoxyglucose to use in the radiopharmaceutical industry. It can be used as a tracer in positron emission tomography scan. Use of this tracer to detect the possibility of cancer metastasis is the most frequent type of PET scan in standard medical care.

Fluorodeoxyglucose also can be applied to evaluate the glucose metabolism in the heart, lungs and the brain, and to image tumors in oncology, where a static F-FDG PET scan is performed and the tumor F-FDG uptake is analyzed according to Standardized Uptake Value. FDG-PET can be used for diagnosis, staging, and monitoring treatment of cancers, particularly in Hodgkin's disease, non-Hodgkin's lymphoma, breast cancer, melanoma, colorectal cancer, and lung cancer. It has also been approved for using in diagnosing Alzheimer's disease. Since fluorine-18 is radioactive and toxic, tungsten radiation shielding is usually used to shield radiation released when producing and using fluorine-18 and its compounds.

Fluorine-18 tungsten radiation shielding is made of tungsten alloy with high density. According to the research, the radiation shielding performance of a metal material is closely related to its density .AS the density is higher, the radiation shielding performance is greater. Therefore the radiation shielding performance of fluorine-18 tungsten radiation shielding is great. Fluorine-18 tungsten radiation shielding is a best choice for shielding radiation generated during the preparation and the use of fluorine-18 and its compounds. In addition, tungsten alloy is environmental non-toxic so as not to pollute the environment or endanger human health.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Doped Tungsten Electrode Morphology Effect by Rare Earth Doping Quantity

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 16:26

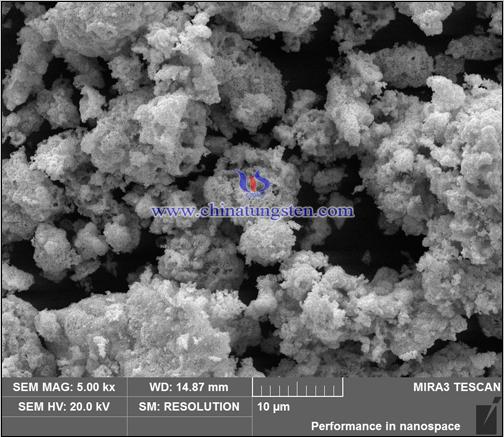

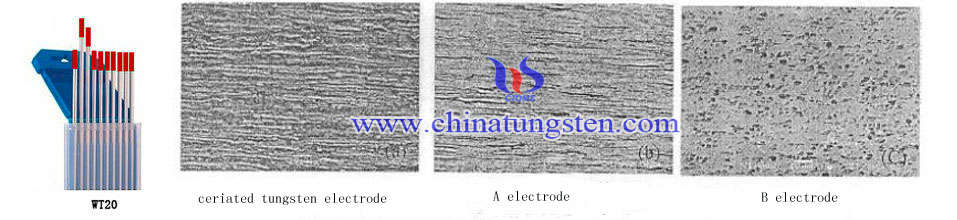

Rare earth doping quantity not only affects rare earth doped tungsten electrode’s welding ability and burning resistance, but also has some impact on electrodes morphology. Using powder metallurgy method to produced tungsten electrodes doped with three rare earth oxides, and according to different rare doping content the electrodes are divided into A electrode and B electrode. The A electrode rare earth ratio is La2O3: CeO2: Y2O3 = 1: 2: 1, and the B electrode rare earth ratio is the ratio of the electrode B is La2O3: CeO2: Y2O3 = 1: 1: 3. Analysis two kinds of rare earth doped tungsten electrodes and ceriated tungsten electrode’s morphology to further understand the impact of rare earth doping amount on rare earth doped tungsten electrode morphology.

Analyzing three kinds of electrode processing states section topography photos found the rare earth oxides in three kinds of electrodes has different shape and distribution. Ceriated tungsten electrode formed a very fine and uniform fibrous CeO2 phase. The A electrode rare earth phase is also fibrous, but uneven, appeared a small amount of fiber breakage. The B electrodes rare earth phase are particles, and the particle and particle link by particle clusters, indicating they are formed by big particles breakage during processing.

After burning test, electrode surface morphology has taken place great changes. Ceriated tungsten electrode tip appeared annular projection, through EDX found them to be cerium oxide, indicating in a large number of cerium oxide enriched to the electrode surface during welding. The A electrode tip has plenty of bulk composite rare earth oxide, and it is composed of smaller particles. The B electrode has special tip morphology. There are many smooth pyramids on matrix surface, which is located in the center of the grain, and a small amount of pyramids has fracture on the top to form some voids. Therefore, the surface of the B electrode is also some small voids, indicating the surface of the B electrode was melted in the welding.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Doped Tungsten Electrode Performance Effect by Rare Earth Doping Quantity

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 16:22

With the development of welding industry, modern industry has higher requirements on electrode welding property, welding stability and pollution standard. Thoriated tungsten electrodes have good welding properties, but it has radioactive contamination, gradually being replaced by other rare earth tungsten electrodes, such as ceriated tungsten electrodes and lanthanated tungsten electrodes. Rare earth oxides having low work function and excellent thermal electron emission property so rare earth doped tungsten electrode has good welding stability and welding ability. However, at AC TIG welding (tungsten argon-arc welding), there are some shortages including poor arcing property, short life and other issues. Tungsten electrode doped with three rare earth oxides is produced for improving these shortages. In general, tungsten electrode doped with three rare earth oxides has better arcing property and welding stability than tungsten electrode doped with two rare earth oxides. In the tungsten electrode doped with three rare earth oxides, different rare earth doping quantity has a certain influence on rare earth doped tungsten electrode welding performance.

Using powder metallurgy method to produce two different rare earth content tungsten electrodes doped with three rare earth oxides, and the electrodes will be divided into A electrode and B electrode. A electrode rare earth oxide ratio is La2O3: CeO2: Y2O3 = 1: 2: 1, B electrode rare earth oxide ratio is La2O3: CeO2: Y2O3 = 1: 1: 3. Comparing these two electrodes with ceriated tungsten electrodes, we will more comprehensive understanding he use performance of electrodes.

These three electrodes were placed on the TIG welding machine, high frequency arcing to test electrode’s welding property and burning loss property, in TIG welding tungsten electrode as a negative electrode, a water-cooled purple copper as the positive electrode. During arc experiments, electrode current is 60A / 120A and arcing duration is 10s / 20min, repeated 10 times in each electrode. From experiment data we knew that B electrode and ceriated tungsten electrodes has better arcing performance and welding performance. A electrode arc performance is general. But burning loss rate of tungsten electrode doped with three rare earth oxides is smaller than ceriated tungsten electrode, so it has better burning resistance property, and B electrode is better than A electrode.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

New Skills of Hitting on Girls—Tungsten Dart

- Details

- Category: Tungsten Information

- Published on Friday, 01 April 2016 16:19

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com