Working Condition Affects Tungsten Trioxide SCR Denitration Catalyst 1/2

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 16:33

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Arc Performance Affected By Tungsten Electrode Organizational Structure

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 16:30

During the welding process, arc performance not only connects with power supply unit and the environmental conditions, it also depends largely on the tungsten electrode’s arc performance. Good arc performance directly determines the use and application range of tungsten electrodes. The organizational structure of the tungsten electrode has a certain impact on tungsten electrode’s arc performance. In general, the integrity and uniformity of the tungsten electrode structure will directly affect the arc performance. If tungsten electrodes inside has splitting, delamination, micro-cracks, voids, mezzanine or severe non-uniform grain structure, the arc process is instability. So it will occur arc breaking, arc blasting, drift, and the worst case will cause thermal and electric, conductivity decreased, so that electrode’s local will overheating, melting, deformation, reducing the arc performance. In addition, at high temperatures, the electrode structure is closely related to the chemical composition. At High temperature, the doped rare earth oxides is easily migration, evaporation, dilution resulting in recrystallization coarsening to cause cracks.

Organizational structure and chemical composition of the tungsten electrode can affect their physical and mechanical properties, thus affecting its arc performance. Tungsten electrode as an important part in welding tool should have good physical and mechanical properties, such as, high melting point, high boiling point, low vapor pressure, good thermal conductivity and electrical conductivity, high temperature strength and high recrystallization temperature and creep and other good properties. If the physical property and mechanical properties of the tungsten electrode is defective, then it can result in electrode deformation and melting during the welding, leading arc performance deterioration. Different type rare earth tungsten electrodes have different deformation resistance and high temperature resistance. In general, tungsten electrode doped with two rare earth oxides is better than pure tungsten electrode and tungsten electrode doped with three rare earth oxides is better than tungsten electrode doped with two rare earth oxides.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Arc Performance Affected By Tungsten Electrode Chemical Composition

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 16:27

Tungsten electrode arc performance is affected by physical and chemical property, mechanical properties, chemical composition and organizational structure. The following will analyzes the influence of tungsten electrode chemical composition on arc performance in welding process.

Pure tungsten electrode has high electron work function and it is not conducive to high electron stream emission, so the service life and arc performance is poor, which directly affect the welding performance. In order to improve the disadvantages of pure tungsten electrode, with further research, manufacturers developed rare earth tungsten electrode and multiple rare earth tungsten electrodes. According to the current density formula of physics emission mechanism Je = AT2exp (-eφ / kT) shows that, in order to reduce eφ (electronic charge), we can add rare earth oxides or other elements in tungsten electrodes to low eφ’s value. Different types of rare earth tungsten electrodes having a particular Je value, so they arc performance are relatively stable.

Tungsten electrodes chemical composition’s type, content, distribution and high temperature characteristics determine the ignition and stability of the arc. In terms of content, taking single rare earth doped tungsten electrode as example, rare earth oxide content is higher, the better the arc performance of the electrodes. In addition, the uniformity distribution and high temperature evaporation and diffusion behavior of rare earth oxides also affected arc performance to some extent. The main reason for arc performance deterioration is caused by doped rare earth’s evaporation and decomposition. Different type rare earth tungsten electrode under different conditions has difference arc performance, tungsten electrode doped with two rare earth oxides is better than pure tungsten electrode and tungsten electrode doped with three rare earth oxides is better than tungsten electrode doped with two rare earth oxides.

Tungsten electrode during operation, the ends of the electrodes will produce ring mushroom nodules, called "Rim" phenomenon. This is because tungsten electrode surface has more added rare earth oxide content than the central portion, in favor of arc in a short time. When the protective gas is mixed with a small amount of O2 or welding parameters transferred to short-term overload state, it will occurs "Rim" phenomenon. This phenomenon is still under study, some scholars believe that this is due to the tungsten oxide and rare earth oxides evaporation, decomposition, precipitation and segregation at the high temperature to occur dephlegmation and segregation precipitation. In fact, it is the chemical composition of the tungsten electrode changed at high temperatures. "Rim" phenomenon is good for arc in short time, but for a long time will lead to surface additives concentration reduction affected arc electrode performance and increased consumption.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TiC Effect on Tungsten Carbide Button Properties (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 16:03

With the increase of the added amount of TiC, its grain refinement, solid solution strengthening effect began to appear, which is beneficial for improving the bending strength of tungsten carbide buttons. And thereafter continue to add TiC, sintered body appeared in the ring structure with non-normal tissue, which is thus the core parts containing lower amounts of solid solution WC and an outer layer containing a high amount of WC solid solution consisting of the ring with will make the structure appear flexural strength decreased more obviously. The variation of fracture toughness is similar to the bending strength.

From the point of view fracture surface, tungsten carbide button after fracture section added TiC is smoother and the distribution is more uniform. And by observing the hard phase of WC and Co binder phase section can be found in WC grains tend to diversify, it also shows that the fracture of the alloy phase is broken along the border and the bonded phase WC grains and binder phase, rarely WC grains through the break, and it is related to the dispersion of fine-grained solid solution with TiC phase of strengthening.

Furthermore, there are some pores in the section, especially the surface of alloy without adding TiC. In the process of solid phase sintering, because of rigid WC skeleton hinder shrinkage during cooling of briquettes contraction and solidification Co generated carbide makes it impossible to completely fill the screen, resulting in the formation of pores shrink tube; on the other hand, uneven distribution and the gas generated during sintering forming agent is one of the reasons. In addition, TiC also has an influence on the routes of cracks expanding. It will have containing and pinning effect on the movements of WC grain boundaries. And owing to a great difference of elastic modulus and coefficient of thermal expansion, the residual stress of TiC and the matrix in the process of sinter cooling, which resulting in cracks in the offset process of moving forward, extending the cracks propagation path.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TiC Effect on Tungsten Carbide Button Properties (1/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 16:02

TiC has higher melting point, boiling point, hardness and excellent chemical stability so that it can be widely used in tungsten carbide materials. In order to analyze the effect of TiC on tungsten carbide button, we study from the hardness, the density, the bending strength, fracture toughness and other mechanical properties. The experiment shows that with the increase of the addition amount of TiC, relative density of tungsten carbide button is rising. This is due to tungsten carbide button without TiC has some internal pores or defects by the raw material and the problems in the overall process, its relative density is lower; on one hand, TiC added refine the micro-structure of tungsten carbide button, on the other hand, ne-grained TiC particles uniformly distributed in the gap between the WC particles were packed efficiently so that the distribution of the alloy grain structure more uniform and reasonable, and thus increased densification of tungsten carbide buttons.

Viewed from the hardness, TiC has better hardness than WC, so with fine grains having a dispersion strengthening effect of TiC added, the hardness of the material also increased. However, when TiC is increased to a certain amount, the hardness of the tooth carbide ball longer because TiC added increasing amounts of rises, inside the material has been basically compact at this time. For the bending strength, with the increase of TiC addition amount of the bending strength of tooth carbide ball was dropped after the first rise and then fall. This is due to the TiC added after sintering temperature is lower than the carbonization temperature, dissolved in WC TiC slow imbalance occurs alloy, WC in solid solution reduced the amount of binder phase of Co carbide wettability deteriorated.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Proper Preservation Methods of Tungsten Gold Plated Coin

- Details

- Category: Tungsten Information

- Published on Thursday, 07 April 2016 15:50

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

BSTN Composite Ceramics with Perovskite and Tungsten Bronze Phases

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 18:23

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Radiation Shielding For GPS

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 18:04

Tungsten alloy radiation shielding for GPS is used for shielding the electromagnetic radiation generated in the using of GPS. The Global Positioning System, referred to as GPS, is a space-based navigation system that provides location and time information in all kinds of weather conditions, anywhere on or near the Earth where there is an unobstructed line of sight to four or more GPS satellites. The system consists of three major segments, which are the space segment, a control segment and a user segment. The space segment is made up of 24 satellites. The control segment is composed of a master control station, a ground antennas and monitor stations. The user segment is GPS signal receiver.GPS has the characteristics of high precision, all weather, short observation time and easy operation.

Tungsten alloy radiation shielding for GPS is used for shielding the electromagnetic radiation generated in the using of GPS. The Global Positioning System, referred to as GPS, is a space-based navigation system that provides location and time information in all kinds of weather conditions, anywhere on or near the Earth where there is an unobstructed line of sight to four or more GPS satellites. The system consists of three major segments, which are the space segment, a control segment and a user segment. The space segment is made up of 24 satellites. The control segment is composed of a master control station, a ground antennas and monitor stations. The user segment is GPS signal receiver.GPS has the characteristics of high precision, all weather, short observation time and easy operation.

Global Positioning System is a satellite navigation system designed to provide instantaneous three-dimensional position information almost anywhere on the globe at any time, and in any weather. With the continuous improvement of GPS, it has been widely used in all fields, and gradually deep into people's daily life. Such as it can be used in the patrol vehicle management to monitor the location information of vehicles for the inspection of the tasks accomplished, and to automatically complete the vehicles dispatch by analyzing the distance from all vehicles to event point and the current state of vehicles. In the car navigation and traffic management, GPS can be used for navigation by aircraft, ships, vehicles and pedestrians; in a navigator, the GPS can achieve the function of map query, route planning, self-navigation and other. GPS systems can also be used in military, fire fighting, logistics and other fields.

GPS is mainly to receive satellite signals through electromagnetic waves. The electromagnetic radiation has radiation characteristic that can cause harm to the body's central nervous system, immune function, cardiovascular system, reproductive system, vision system. Therefore, it should be accompanied by the use of certain radiation protection measures (such as using tungsten alloy radiation shielding for GPS) to protect the human body when using GPS. Tungsten alloy radiation shielding for GPS has good radiation shielding ability, and can shield electromagnetic radiation to avoid human suffering from radiation damage in the long-term electromagnetic radiation environment.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

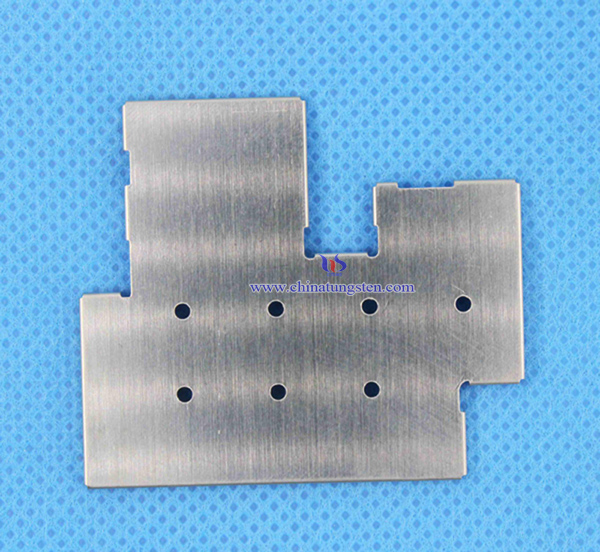

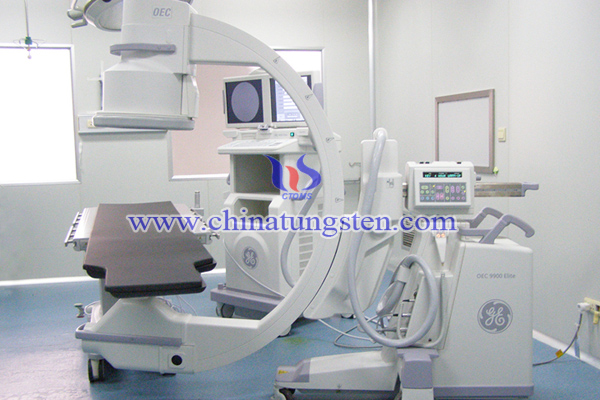

Tungsten Alloy Radiation Shielding For DSA System

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 18:01

Tungsten alloy radiation shielding for DSA system is a tungsten alloy shielding used for digital subtraction angiography system. DSA system, also known as digital subtraction angiography system, is a new x-ray imaging system to clearly visualize blood vessels in a bony or dense soft tissue environment by computer. Images are produced using contrast medium by subtracting a ‘pre-contrast image’ or the mask from later images, once the contrast medium has been introduced into a structure. Compared to the conventional angiography system, images obtained by digital subtraction angiography system are more clearly and intuitively, even some fine vascular structures can be displayed.

Digital subtraction angiography system is suitable for the examination of heart and great vessels. It clearly shows the structural abnormality of heart anatomy, coronary, aortic coarctation, aortic dissection, aortic aneurysm, developmental anomaly of aorta, etc; and also clearly shows the cervical segment and intracranial arteries for diagnosing intracranial aneurysms, cervical artery stenosis or occlusion, vascular anomaly, arterial occlusion and for observation of intracranial tumor‘s feeding artery. In addition, digital subtraction angiography system can be used to check large blood vessels, abdominal aorta and its branches. At the same time, digital subtraction angiography system can also be used for the interventional treatment in all parts of the body lesions, such as interventional embolotherapy in treatment of liver cancer, cerebral aneurysms, cerebral arteriovenous malformation,and percutaneous balloon mitral valvuloplasty, percutaneous puncture biopsy.

Digital subtraction angiography system is suitable for the examination of heart and great vessels. It clearly shows the structural abnormality of heart anatomy, coronary, aortic coarctation, aortic dissection, aortic aneurysm, developmental anomaly of aorta, etc; and also clearly shows the cervical segment and intracranial arteries for diagnosing intracranial aneurysms, cervical artery stenosis or occlusion, vascular anomaly, arterial occlusion and for observation of intracranial tumor‘s feeding artery. In addition, digital subtraction angiography system can be used to check large blood vessels, abdominal aorta and its branches. At the same time, digital subtraction angiography system can also be used for the interventional treatment in all parts of the body lesions, such as interventional embolotherapy in treatment of liver cancer, cerebral aneurysms, cerebral arteriovenous malformation,and percutaneous balloon mitral valvuloplasty, percutaneous puncture biopsy.

Since digital subtraction angiography system is an X-ray angiography system basing upon image subtracting. And X rays can inhibit, destroy or even kill biologic cells, causing different degrees of changes in physiological, pathological and biochemical aspects of organism. Therefore, it is need to use a tungsten alloy radiation shielding to shield and absorb X rays when using the digital subtraction angiography system. Tungsten alloy radiation shielding for DSA system has excellent radiation shielding performance to shield radiation and avoid it damaging human body.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding For Radioactive Tracer Technique

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 April 2016 17:57

Tungsten alloy shielding can be used to shield the radiation released from the radioactive tracer technique. Radioactive tracer technique is used to track the passage of a sample of substance through a system. The substance is "labeled" by including radioisotopes in its chemical composition. When these decay, their presence can be determined by detecting the radiation emitted by them. Then the movement condition and change rule of the substance can be distinguished. Radioactive tracer technique has the characteristics of high sensitivity, high quantitative accuracy, simple method, accurate localization and conforming to the physiological conditions, etc.

Tungsten alloy shielding can be used to shield the radiation released from the radioactive tracer technique. Radioactive tracer technique is used to track the passage of a sample of substance through a system. The substance is "labeled" by including radioisotopes in its chemical composition. When these decay, their presence can be determined by detecting the radiation emitted by them. Then the movement condition and change rule of the substance can be distinguished. Radioactive tracer technique has the characteristics of high sensitivity, high quantitative accuracy, simple method, accurate localization and conforming to the physiological conditions, etc.

Radioactive tracer technique has been widely used in industrial production, agriculture and animal husbandry, health care, life sciences, and other fields. In agriculture and animal husbandry, it can be used to study the fertilizer absorption rule of crops and discovery the life cycles, migratory habit, mating behavior and foraging behavior of insects, parasites, fishes and animals; in medicine, it is mainly used for the diagnosis of the disease; in industrial production, it provides the possibility of using a variety of high-efficiency testing methods and automatic control methods for the production process, solving many technical and theoretical issues, such as determining the diffusion rates of certain elements within the metal sheet; in the life sciences, it can dynamically observe the physiological and biochemical processes within the cell or in vivo at molecular level, understanding the material basis of life activities. Check the chemical reaction process of research of environmental pollution radioisotope tracer technique can also be used. Radioactive tracer technique can be also used for the detection of environmental pollution and research of a chemical reaction process.

Radioactive tracer technique has found an increasingly wide utilization in our life. But due to the rays released form it will cause harm to human body, the use of tungsten alloy radiation shielding in the radioactive tracer technique is necessary. Generally, tungsten alloy shielding is made up of tungsten heavy alloy which has high density and great shielding effectiveness. Thus tungsten alloy shielding can shield the radiation to protect the staff from radiation damage.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com