The Classifications of EB Tungsten Filament

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 18:25

All EB (electron beam) tungsten filaments are made of tungsten which is also known as wolfram. The EB tungsten filament has a good discharge performance and an excellent anti-sag performance. The two characteristic can ensure that the filament is not deformed during working. The following classifications are the main types of EB tungsten filament.

|

Classification |

Specification |

Picture |

|

Mosquito Coil: the shape of the EB tungsten filament is similar to the mosquito coil, therefore, it can be named as Mosquito Coil. And the Mosquito Coil can be divided into the following specifications. |

0.55mm |

|

|

0.65mm |

|

|

|

0.80mm |

|

|

|

Pull-type: Pull-type is also known as the cavity type of Mosquito Coil. |

0.80mm |

|

|

Classification |

Specification |

Picture |

|

U-shaped: this kind of EB tungsten filament is similar to the shape of the letter U. |

0.80mm |

|

|

U-shaped with folding legs: the feet of the EB tungsten filament has a curved. |

0.80mm |

|

|

Half Moon: the shape of this type is the shape of a half moon. |

0.80mm |

|

|

Straight shape |

0.80mm |

|

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Low-NOx Combustion Unit Uses Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 18:24

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

CaO Effects Designing WO3 Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 18:19

Calcium oxide (CaO), the so-called quicklime, is an inorganic compound powder with white, hygroscopic and corrosive. The plaster (Calcium sulfate) in thermal power plant is generated by sulfur dioxide reacting with desulfurization and then oxidized, and then discharged with the flue gas exhaust system. When it comes into being that calcium sulfate contacts with tungsten trioxide SCR denitration catalyst, large number of calcium sulfate will be deposited on the surface of the catalyst, which can cause the catalyst surface shielding, and then the catalyst activity decreased.

Calcium oxide (CaO), the so-called quicklime, is an inorganic compound powder with white, hygroscopic and corrosive. The plaster (Calcium sulfate) in thermal power plant is generated by sulfur dioxide reacting with desulfurization and then oxidized, and then discharged with the flue gas exhaust system. When it comes into being that calcium sulfate contacts with tungsten trioxide SCR denitration catalyst, large number of calcium sulfate will be deposited on the surface of the catalyst, which can cause the catalyst surface shielding, and then the catalyst activity decreased.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

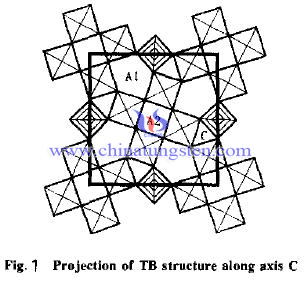

Tungsten Bronze (TB) Crystal Structure

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 17:58

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Ball for Universal Joint (2/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 16:16

Tungsten carbide ball is composed of hard phase WC and binder phase Co. It has higher hardness, strength, excellent wear resistance and chemical stability, which is the ideal material for universal joint. In the arc type universal joint, the active fork ball and do some carbide groove driven fork mounted four synthetic carbide ball raceway can accommodate four carbide balls. Besides, there is a spherical ball mounted in the center of the groove as centering ball. Straight groove raceway-type universal joint in the two fork ball with carbide straight grooves, straight grooves and each axis is inclined relative to the center line and the same tilt angle and symmetrical to each other. Built in the raceway between the two fork ball has four tungsten carbide balls.

Velocity joint cage can be divided into stationary and scalability ball basket universal joints according to the movement of the universal joint axial direction. Viewed from the structure, fixed cage universal joints are composed of spline, star sets, curved groove. Star spherical shell fitted jacket and synthesized six races, each mounted in each race a carbide ball and keep cage carbide ball inside in the same plane. It powered by a drive shaft through a spherical shell and tungsten carbide ball. The structural feature of scalability ball basket universal joints is the inner wall of the cylindrical shell of the star and the external cylindrical sleeve made straight slot, built-in two raceways fitted together after the formation of cemented carbide ball. Star set bore splined for connection with the input shaft, which allows relative movement of the tubular sleeve in the axial direction. Overall, due to high hardness, high strength, wear and corrosive resistance, tungsten carbide ball has a broad application prospect in universal joints.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Ball for Universal Joint (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 16:14

Universal joint like joint on human limbs, it is a kind of component that change the angle and achieve power transmission, which is also called universal connect. Universal joint can be usually seen in driving system gear in cars or some mechanical equipment, whose main role is to change the position of the shaft line direction. On the front-engine rear-wheel drive vehicles, the universal joint transmission device is installed between the transmission output shaft and the drive axle final drive input shaft; while the front-engine front-wheel drive vehicle is omitted, drive shaft, universal joint mounted between the drive and is also responsible for steering the front axle and the wheel axle.

According to elastic twist direction, it can be specifically divided into rigid and flexible universal joint. Flexible universal joint assembly is mainly composed of elastic rubber-like, temporarily go into details here. We discuss the most common rigid joints in constant velocity joints here. As the name implies constant input shaft and output shaft universal joint is connected is always equal to the instantaneous angular velocity of the transfer direction of movement section, which can be subdivided into fork-ball constant velocity joints and constant velocity joints ball basket. Fork-ball constant velocity joint consists of two fork ball with raceway and ball composition. It is unavoidable that the groove and ball will endure friction, impact and other interactions during the process, especially will probably be contacted with some corrosive liquid, which put higher requirements for the materials.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

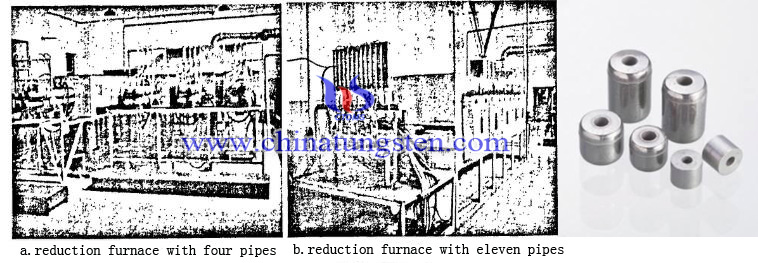

Tungsten Electrode Production Technology - Hydrogen Reduction

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 11:54

Rare earth tungsten electrode greatly improved pure tungsten electrode welding performance and greatly broadened in welding, plasma welding, cutting, painting and other areas application. The production techniques failed to break greatly constricts rare earth tungsten electrode industrialization production. Therefore, to study tungsten electrode production technology has a certain significant on tungsten electrodes volume production and application field expansion. The production processes of tungsten electrode include raw material doped-pressing-pre-sintered- sintered-swaging process-recrystallization annealing-drawing-straightening-polished and so on.

Using two-step hydrogen reduction method to obtain elemental metal tungsten and uniformly doped rare earth oxide powder, using hydrogen as reducing agent. The main reactions in reduction reaction are rare earth nitrate decomposition, APT decomposition and tungsten oxide reduction. China is the largest tungsten and related products producer, thus reducing furnaces in industrial production have high automation level and can automatic control a plurality of temperature zones’ temperature. During the reduction process, adjusting each temperature zone reduction temperature, generally obtained powder particle size are in line with production requirements. The first reduction general operated in reduction furnace with four pipes, and the second reduction operated in reduction furnace with eleven pipes. The whole reduction process is divided into five temperature zones and the third temperature zone is the highest.

Tungsten powder and rare earth oxide powder’s average particle size and bulk density is quality standard. Bulk density refers to per unit volume freedom filled tungsten powder’s weight, usually showing g/cm3, and it is a simple and fast way to evaluate thickness of the powder. The average particle size is another reference index for particle thickness testing.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

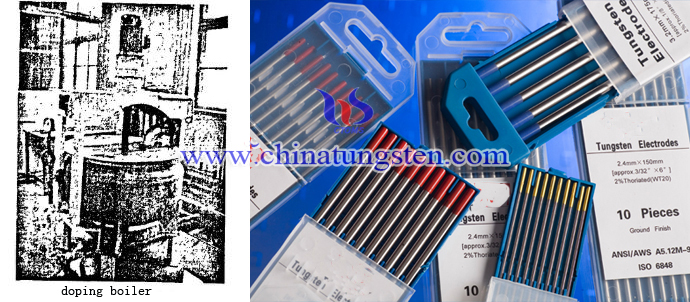

Tungsten Electrode Production Technology - Doping Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 April 2016 11:51

Tungsten electrode used in welding, cutting, painting and metallurgical industry is more and more widely. Pure tungsten electrode has higher electron work function, therefore it is difficult to arcing and arcing stability is also poor. Adding rare earth oxides can improve the pure tungsten electrode welding performance to improve the shortages of pure tungsten electrode, thus greatly expand the application areas of the electrodes. The common rare earth tungsten electrodes include thorium tungsten electrodes, cerium tungsten electrode and lanthanum tungsten electrode.

Tungsten electrode usually uses powder metallurgy method to produce. The main processes include doping, mixing, pressing, pre-sintered, sintered to produce blank, then through multistage swaging process recrystallization annealing, drawing straightening, polishing and a series of processes to get the finished products. Tungsten electrode production processes are complex, from the original powder doped to obtain the finished product to be subjected to more than a dozen steps, interlocking and interaction between each step. Therefore control tungsten electrode‘s production process, to develop a reasonable process parameters for obtain high-performance tungsten electrode has great significance.

Doping process is the first step of tungsten electrode production. Whether uniform doped rare earth or not will have direct impact on tungsten electrode performance. Earlier doping method is solid-solid method to doping with tungsten oxide doped and other rare earth oxides, but the effect is not ideal. After continuous improvement on doping method, at the present manufacturers usually use solid-liquid doping method. Solid-liquid doping mainly doped tungsten oxide with rare earth nitrate solution. This solid-liquid doping method greatly improves doping uniformity and improves tungsten electrode’s performance.

Putting a certain proportion of tungsten oxide and rare earth nitrates into the doping pot, when tungsten oxide was thoroughly wetted by the rare earth nitrate solution, to start doped pot impeller, heated with stirring to achieve uniform doping .

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ways to Judge the Polluted IG Tungsten Filament

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 17:59

The IG tungsten filament is known as the ion source which is a discipline with a wide range of applications. The IG tungsten filament is indispensable equipment in many basic research areas, such as atomic physics, plasma chemistry, and nuclear physics research. However, to a certain degree, the IG tungsten filament will be polluted because of the prolonged using of the IG tungsten filament. It requires the users have knowledge about the ways to judge whether the IG tungsten filament is polluted or not. Here are several ways can help people make a judgment.

The first method is to make a preliminary judgment of the Repeller.

Minor pollution:

1. Install the number of Repeller into 0.1, the IG tungsten filament cannot achieve the desired sensitivity.2. Auto-tuning would increase voltage of Repeller, or increases voltage of PMT.3. People can notice the obvious change of the reaction of the peak value of voltage if increase the Repeller. The above three conditions are minor pollution

Serious pollution:

1. IG tungsten filament still cannot get the expected sensitivity under a very high value PMT condition.2. The voltage of Repeller must be increased to a very high value so that the IG tungsten filament can achieve the expected sensitivity.

Another way is to make a judgment of the IG tungsten filament. The main way is to look at the filament current, the most obvious signs of the polluted IG tungsten filament is the filament current becomes large, the greater the current, the more serious pollution it exists. Therefore, when using the IG tungsten filament, users should ensure the safety of the vacuum system, the filament must not be opened in a case of leakage, or it would burn out the filament quickly.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Life Time of EB Tungsten Filament

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 17:57

The cathode of EB tungsten filament plays a fundamental role in the life length of EB tungsten filament, and the cathode’s material and temperature are the key factors. Therefore, when selecting the cathode material, a low work function material is the best choice.

There are two main factors to affect the life length of EB tungsten filament.

One is subjective reasons, heating emission requires a high temperature of the filament and the filament evaporation rate is proportional to the temperature index, the higher the temperature, the faster the evaporation rate of the filament. Therefore, under the condition of usage, user should try to ensure that the low temperature of EB tungsten filament, which is important for life length of the filament.

Another is objective reasons: the surface of EB tungsten filament is easy to form a tungsten oxide layer due to the leakage of vacuum, and the evaporation rate of the tungsten oxide is N times higher than that of the elemental tungsten. If there exists oxygen inside the bulb and under high temperature conditions, the reaction between EB tungsten filament and oxygen will blow the filament. As a result of it, the life length of EB tungsten filament will be significantly shortened. In addition, the moisture content of air has a certain influence on life length of the EB tungsten filament. Humidity will greatly reduce the life length of EB tungsten filament.

The life length of EB tungsten filament is limited. And the life length would change because of habits of the user. The EB tungsten filament requires a high vacuum environment and minimizes pollution, so the user should cultivate the habit of maintaining a vacuum system to prevent vacuum from leaking.

In short, although the quality of EB tungsten filament will influence its life length, users’ maintenance is more important, therefore, users should strengthen the management of the EB tungsten filament.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com