Reasons for the Crack of Tungsten Crucible Bottom

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:30

As the main tungsten product, tungsten crucible is widely applied in smelting of rare earths and the demand of it is also increasing for rare earth industry. However, the crack of tungsten crucible bottom will directly influence in the rate of finished tungsten crucible products during the productive process. Operating engineer should pay attention to the reasons for the crack of tungsten crucible bottom and find out the solution to solve those problems, so that the rate of finished tungsten crucible products can be improved. According to researchers, they show that reasons for the crack of tungsten crucible bottom mainly lie in the pressing step and sintering step.

During the pressing process, if people select the thicker tungsten powder which would be difficult to suppress. It would result that the pressed compact higher needs a higher sintering temperature or more holding time in the next step sintering. What’s more, the thicker tungsten powder would waste much energy and time and has a great impact on the life time of the equipment. In the selection of the powder, in general, the thicker the tungsten powder is,the worse the compressibility is. And it would cause that users should choose a more large size of the mold cavity while filling it. A large powder needs for more pressure during the pressing. Except that, its compression is poor and it would directly reduce the density of the pressed compact. Therefore, when choosing the size of the powder, users should choose different sizes. The small size particles can fill the space leaving by large particles in the process of pressing to increase the density of compacts to avoid being cracked. In addition, the pressure of the pressing process also affects the qualified rate of the tungsten crucible compacts. Moreover, the qualified rate of the tungsten crucible compact is also affected by the hardness of the rubber sleeve, the greater the hardness, the more likely cause cracks.

During the sintering process, the selection of equipment and the sintering atmosphere has a greater impact on the qualified rate of the tungsten crucible. It’s required that tungsten crucible should be under a anaerobic condition, but there still exist oxygen on the surface of tungsten powder, the oxide film of its surface would hinder the sintering process. Oxygen of tungsten powder will be greatly removed in a hydrogen atmosphere which would increase the density of the product. In the selection of the sintering equipment, electric resistance furnace would be better than the induction furnace. The temperature of the upper and lower ends of the induction furnace is much lower than the middle part because of its structure, which would result in nonuniform sintering of tungsten crucible bottom.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Development of Tungsten Crucible in China

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:28

China is one of the richest tungsten resources storage countries in the world. Therefore, as deep processing product of tungsten, tungsten crucible industry has been continuously developed in China. The main applications of tungsten crucible in China are rare earth smelting, quartz glass, electronic spraying, crystal growth, etc.

Nowadays, our country has a production capacity for some conventional tungsten crucible, but there still exist some problems for the high-tech products. For example, the manufacturing technique for complex shape of the tungsten crucible is relatively rare, but such products play an important role in the area of high technology. And for instance, quartz glass has been widely applied in laser technology, astronomy and sophisticated technology. With the rapid development of modern technology, as the core components of quartz glass, tungsten crucible has a wide range prospects for development. The next few years, the development direction of the tungsten crucible will be large-size, high-quality, low-cost characteristics of tungsten crucible

With the rise of the tungsten industry in our country, the exploitation of tungsten resources has become a major problem. Our country has been exporting tungsten raw materials for a long time, which will affect the production of tungsten crucible. On the other hand, the utilization of the tungsten crucible is not enough. Tungsten Crucible has a long life time for using so that users can reuse it for many times. It can not only save costs but also protect the ecological environment. In addition, changing the export structure of the tungsten crucible which can save a lot of foreign exchange and improve our economy.

In recent years, the rapid development of chemical vapor deposition of can produce complex shape tungsten products in China. This is an important research direction of pure tungsten manufacturing technique. Such tungsten crucible that made by chemical vapor deposition process will be gradually on the market. Isostatic - sintering process in our country has reached the international advanced level and the scale of China's tungsten crucible development would be expanded with continuously improvement of the process. With the deepening of China's tungsten crucible research, international influence of domestic tungsten crucible is gradually rising, the tungsten crucible industry of China will occupy a major position in the international area in the future.

Applications of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:26

The main raw material of tungsten crucible is tungsten, and it is mainly formed through the deep processing of tungsten. Thanks to the high melting point and boiling point, a good thermal conductivity, low thermal expansion coefficient, a strong abrasion and corrosion resistance and other excellent properties of tungsten, tungsten crucible is widely applied in smelting of rare earth, quartz glass and crystal growth industries.

As an important member in the smelting of rare earth, functional performance and life time of tungsten crucible is very important. In the past, smelting of rare earth mainly use crucible which is welded by tungsten, molybdenum, or tantalum slab. But because there are many problems of this kind of crucible which would have seriously impact on their life time. The problems of welded crucible are more serious for high temperature or high purity rare earth metals. welding production out of the crucible short life is even more obvious. To solve this problem, the researchers developed a sintered tungsten crucible which can deal with the problem of crack of welding process. Sintered tungsten crucible has a high density, a high purity, long life time and other properties which make the rare earth smelting industry pay more attention to it. Compared with other types of crucibles, on the one hand, tungsten crucible would produce less pollution when smelting metal. On the other hand, its life time is longer, so the tungsten crucible is widely applied in rare earth industry.

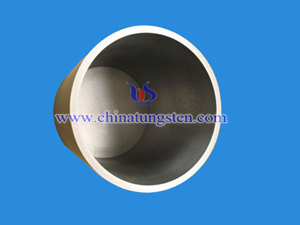

Because of the melting point of tungsten can reach 3600℃, tungsten crucible can be considered as the cord cage and widely applied to the furnace of sapphire products. And the temperature tungsten crucible is generally above 2000 ℃ while working. Especially for sapphire products furnace, characteristics of a high purity, high density, crack-free, precise size, smooth inner and outer walls of the tungsten crucible can greatly improves the success rate of seed of the growth of sapphire crystal. In addition, tungsten crucible also plays a key role in controlling the quality of crystal pulling and the life time of sapphire products.

Quartz glass is an amorphous material which is only made of silica. The raw materials of it are crystal, silica and silicide, and quartz glass can be formed by high temperature melting or chemical vapor deposition. Therefore, it need for a high melting point and boiling point tungsten crucible as the core cage. In addition, the tungsten crucible can also greatly improve the rate of finished quartz glass.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Prepare WO3 Plate SCR Denitration Catalyst--Dry Powder Mixing Method

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:23

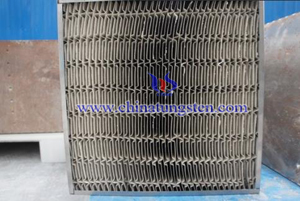

The main component of tungsten trioxide plate denitration catalyst is just similar to honeycomb denitration catalyst, both are based on vanadium pentoxide, tungsten trioxide as the main active substance, titanium dioxide as the carrier. Compared with cellular, it has a stronger capacity of ash anti-clogging, wear resistance, less consumption under dust and low pressure loss ect.; although its market share is only about 1/3 of the cellular, it will gradually expand with the further launch of high-dust flue gas denitration in China.

The main component of tungsten trioxide plate denitration catalyst is just similar to honeycomb denitration catalyst, both are based on vanadium pentoxide, tungsten trioxide as the main active substance, titanium dioxide as the carrier. Compared with cellular, it has a stronger capacity of ash anti-clogging, wear resistance, less consumption under dust and low pressure loss ect.; although its market share is only about 1/3 of the cellular, it will gradually expand with the further launch of high-dust flue gas denitration in China.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

TiO2 Affects Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:21

Nitrogen oxides is one of the main air pollutants, the large amount of NOx emitted into the air will not only cause a serious threat to the global environment, but also have an adverse effect on human health. The core of the current widespread use of SCR denitration technology is the catalyst, which the main active component is vanadium pentoxide; tungsten trioxide itself also has a denitration capability, besides it plays an important role in anti-toxic, anti-sintering, furthermore, it increases the ability of anti-oxidation of sulfur dioxide; titanium dioxide has a good sulfur resistance and stability, and join improving of the catalyst activity with the active ingredient.

Nitrogen oxides is one of the main air pollutants, the large amount of NOx emitted into the air will not only cause a serious threat to the global environment, but also have an adverse effect on human health. The core of the current widespread use of SCR denitration technology is the catalyst, which the main active component is vanadium pentoxide; tungsten trioxide itself also has a denitration capability, besides it plays an important role in anti-toxic, anti-sintering, furthermore, it increases the ability of anti-oxidation of sulfur dioxide; titanium dioxide has a good sulfur resistance and stability, and join improving of the catalyst activity with the active ingredient.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contacts Cryogenic Treatment (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:13

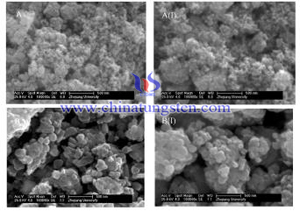

At present, cryogenic treatment mainly applied in tool steel, non-ferrous metal applications under development step, here we discuss that the tungsten copper contacts cryogenic treatment process conditions affect its properties. Tungsten copper contact is a psudoalloy, which is composed of two kinds of immiscible and has a great difference in physical and chemical properties metals. There is no phase change in the reaction and it is brittle so that it is difficult to adapt conventional heat treatment hardening process to improve its relative performance. Cryogenic treatment is undoubtedly an ideal choice.

Viewed from the micro-structure, after cryogenic treatment, W matrix disperse a large number of Cu phase and the organization has significantly refined, which is due to precipitation of Cu solute in W after cryogenic treatment. In addition, it also can be found that with the increase in the copper content, the segregation phenomenon is also becoming increasing apparently. Copper particles dispersed precipitated tissue thinning, and atomic displacement volume shrinkage, tungsten copper contact density and overall strength has also improved.

While its hardness and strength has greatly improved after cryogenic treatment, and electrical conductivity with increasing tungsten content decreases. This is due to cryogenic treatment makes a lot of precipitated Cu and W form a solid solution, and is proportional to the electrical conductivity of tungsten copper contacts with the copper content. Overall, tungsten copper contacts after cryogenic treatment, may be little alternative to tungsten copper copper-tungsten less, not only improves performance, but also reduce costs.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contacts Cryogenic Treatment (1/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 16:12

Cryogenic treatment refers to process the blank at -190℃-230℃, which has a broad application prospect, such as non-ferrous metal, ferrous metal, metal alloy, carbide, plastic, silicate and so on. The basic principle is that in the process of metal hardened to cooling by heat treatment, which produces alloy and carbon dissolved and combined with the formation of austenite(Austenitic is a lamellar microstructure, usually ɣ-Fe solid solution in a small amount of non-magnetic solid solution of carbon) and diffusion; in the cooling process, since the low temperature produce suppress the formation of martensite(The crystal structure of martensite is body-centered tetragonal (BCT). High carbon steel is usually accelerated cooling to obtain such organizations and high strength and hardness of steel is one of the main features of martensite.), the final transition point (Mf) is definitely low.

Austenite is very unstable and easily decomposes at low temperature, so the original defects (pores and internal stress concentration part) and becomes plastic flow structure refinement. Therefore, as long as put the metal at ultra-low temperature, the austenite is converted into martensite, which eliminates the internal stress. In addition, due to the contraction of the tissue volume at ultra-low temperature, Fe lattice constant decreases and the driving force to strengthen the precipitation of carbon atoms, so a lot of martensitic matrix deposited ultrafine carbides. The strength of these ultra-fine crystalline materials will improve and increase the wear resistance and rigidity. And Ultra-low temperature can also be transferred metal atom transport capacity, which makes the atoms can not be separated and become closer.

There are some experiments shows that high-pressure vessel after cryogenic treatment can meet the requirements of the strength of solid propellant rocket; some down-hole equipment for sour oil field after cryogenic treatment can improve the corrosion resistance and the welding cracks; some parts of the alloy cryogenic treatment, volume stability, dimensional stability and strength has been greatly improved.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Classifications of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 April 2016 18:33

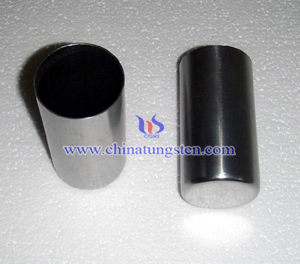

As a kind of tungsten metal products, tungsten crucible has some very excellent properties, such as a high melting point, a high boiling point, a strong anti-friction resistance and the coefficient of thermal expansion is very small. Nowadays, tungsten crucible is widely used in rare earth smelting, quartz glass, electronic spraying and other industries because of those excellent properties. Moreover, China is the most resource-rich countries of tungsten in the world. Therefore, the related applications of tungsten crucible have also been rapid development. According to the manufacturing process of the tungsten crucible, it can be mainly divided into two types: forging type and sintering type. The two types will be briefly described in the next part.

Forging Tungsten Crucible: Forging process is a manufacturing process which can make metal billet become plastic deformation by using localized compressive forces to obtain the forging parts with a mechanical energy, and a relatively shape and size. The raw material of forging tungsten crucible is a solid tungsten rod. After processing of the lathe system, then tungsten crucible can be produced. The advantage of the forging tungsten crucible is a high density. What’s more, it is not susceptible to be corroded with a longer life time.

Forging Tungsten Crucible: Forging process is a manufacturing process which can make metal billet become plastic deformation by using localized compressive forces to obtain the forging parts with a mechanical energy, and a relatively shape and size. The raw material of forging tungsten crucible is a solid tungsten rod. After processing of the lathe system, then tungsten crucible can be produced. The advantage of the forging tungsten crucible is a high density. What’s more, it is not susceptible to be corroded with a longer life time.

Sintering tungsten crucible: It refers to a conventional sintering process which would make powdery raw materials into the dense bodies. The raw material of sintering tungsten crucible is tungsten powder. After firing the molding, sintering tungsten crucible would be produced by lathe working. Sintering tungsten crucible can be characterized by the production of large-size of tungsten crucible.

Tungsten crucible has a high temperature oxidation resistance and resistance and a strong electrochemical corrosion resistance, so it is a relatively good material for high temperature supporting. Although there are many advantages of forging tungsten crucible and sintering tungsten crucible, there still exist some serious problems. For example, during the sintering process of the sintering tungsten crucible, agglomerate cannot deliver the heat to the blast furnace because of the high temperature. Even if people can recover the part of the waste heat, sintering processing still release a large amount of waste heat. It would have a great effect in ecological environment. In terms of the environment, people should know more about the recovery details of it to improve the development of tungsten industry.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Manufacturing Techniques of Tungsten Crucible: Plasma Spraying, Chemical Vapor Deposition, Rivet Linking and Welding

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 April 2016 18:31

Plasma spraying process: First of all, users should prepare a suitable graphite mandrel for finished tungsten crucible product, and then fixed it on an airtight turntable. When sealed housing is in a vacuum condition, and then adds argon with a high purity. After spraying the surface of graphite mandrel by plasma spraying equipment, spraying it until the size and the quality can meet the design requirement. And it is time to cool it. Finally, tungsten crucible can be formed by machining process.

Chemical vapor deposition (CVD): It is a chemical process used to produce high quality, high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films. If people want to use this way to produce tungsten crucible, the main raw materials are tungsten hexafluoride and hydrogen. Both of them can be oxidized into vapor deposition of tungsten atoms. After that, there exist settled player of tungsten on surface of matrix. Until the settled player increase to a certain degree, basic shape of tungsten crucible is formed. Finally, a finished tungsten crucible will be produced by the treatment process and annealing process.

Rivet linking and welding process: This process includes rivet linking and welding. Rivet linking refers to two or more metals are linked by rivets, and people often use rivet to link two tungsten plates. Welding is a manufacturing or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. Use this way to produce the tungsten crucible, the first step is to make tungsten plates into tungsten tube. And then, link it with a round tungsten plate to produce the finished tungsten crucible.

Tungsten crucible belongs to the deep processing of tungsten products and it has a very high added value. Therefore, many researchers are working on manufacturing techniques of tungsten crucible. So far, manufacturing techniques of tungsten crucible have been widely used in various products. The most common process is isostatic - sintering process, forging and Rivet linking and welding process. Manufacturing techniques of the three processes are more mature, and quality and stability of production are better by using the three process.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Manufacturing Techniques of Tungsten Crucible: Isostatic - Sintering, Forging, Spinning

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 April 2016 18:28

With the rapid development of tungsten industry, the market demand for tungsten crucible is gradually increased, and the requirements of quality for product are more strictly. Therefore, the manufacturing techniques and properties of tungsten crucible play a significance role in the development and utilization of tungsten materials. There will be a brief analysis of these threemanufacturing techniques.

Isostatic - sintering process: Nowadays, it is one of the most important manufacturing techniques for the industrial tungsten crucible production. This technique consists of preparing raw materials, loading powder, isostatic pressing, sintering at a high temperature, lathe processing, product testing, etc. First of all, mold should be assembled according to the required size of products. And then tungsten powder material that has reached the national standard should be put into a mold and the mold must be sealed immediately. Next is to put it in an isostatic press with a pressure of 180-250MP. After that, the pressed compact should be sintered in a high temperature induction sintering furnace under super-heating rate sintering between 80 degrees centigrade and 150 degrees centigrade one hour. The holding time should last for 4 or8 hours. Finally, process the product in accordance with its requirement. After processing, it is time to test the appearance size, density of finished product.

Forging process: Forging process is a manufacturing process involving the shaping of metal using localized compressive forces. Adopting this process to make tungsten crucible mainly consist of three steps: billet preparation, forging and machining. In general, the relative density of the billet is between 90% and 95%. In the preparation of the billet, the size and quality of the tungsten rod are needed to calculate in accordance with the requirements of the finished product. Then put the tungsten rod in a hydrogen furnace to heat under a temperature of 1400-1600 ℃. After keeping warm for a while, forging the billet, and then repeated heating and forging billets for some times until the size of billet meet the requirements. After the forging, the billet can be annealed, and then processed in accordance with the size and the outlook of the finished product.

Spinning process: When use this method for making tungsten crucible, users should prepare tungsten billet before. And then make it into a sheet which conforms to the design by hot-rolling process to hot-rolled, and process it into a few pieces of wafers, and put it on a hot spinning machine. After that, heating mixed flame which consists of hydrogen and air mixing. And after spinning for several times, the shape tungsten plate becomes the shape of the tungsten crucible, and finally cools it into finished tungsten crucible.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com