Merits and Drawbacks of Manufacturing Techniques of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Friday, 22 April 2016 16:47

Tungsten crucible is an important deep-processing product of tungsten. As the main manufacturing techniques of tungsten crucible, isostatic pressing - sintering, forging, chemical vapor deposition, plasma spraying, a spinning and rivet linking and welding process have their own characteristics. Properties of tungsten crucible made by different manufacturing techniques also have some differences. The following is a brief analysis for merits and drawbacks of the six manufacturing techniques of tungsten crucible.

Isostatic pressing - sintering: Most of tungsten crucible are mainly made Isostatic pressing - sintering process. It has a high maturity because of a long history development. The main process of this manufacturing technique is pressing. Quality of the finished tungsten crucible made by isostatic pressing - sintering process is relatively stable. And it can produce large-size products. But it is easy to crack the bottom of tungsten crucible because the improper operation in the pressing process.

Forging: Forging is a key step of manufacturing techniques. The density of tungsten crucible made by this process is relatively high, therefore, anti-deformation and higher-temperature deformation resistance of such tungsten crucible are better than other types of tungsten crucible. However, forging process is finished by the processing of tungsten rod, so it has a lower utilization of materials. And the diameter of products made by forging is much small.

Forging: Forging is a key step of manufacturing techniques. The density of tungsten crucible made by this process is relatively high, therefore, anti-deformation and higher-temperature deformation resistance of such tungsten crucible are better than other types of tungsten crucible. However, forging process is finished by the processing of tungsten rod, so it has a lower utilization of materials. And the diameter of products made by forging is much small.

Chemical deposition process (CDV): With the continuous research and development of chemical deposition process in recent years, the maturity of it becomes much higher. The density of tungsten crucible made by this process is high, and it can produce the large size tungsten crucible with a thin wall. However, because of the short developed time, the maturity of the technology is not enough.

Plasma spraying forming: This process is capable of producing large size tungsten crucible. However, due to the size of the tungsten powder, internal organization of finished tungsten crucible is not tight enough, which will produce more pores, and result in density of tungsten crucible cannot reach a high standard.

Spinning: This process can produce high-density products. However, due to complexity of hot rolling process and the spinning process, it is difficult to operate.

Rivet linking and welding: Rivet linking and welding is capable of producing large size tungsten crucible products with thin wall. However, the metal welding process is the key step of rivet linking and strength of the metal junction is low.

Different manufacturing techniques have different advantages and disadvantages, the users should choose a different preparation process in according with the requirements of the finished tungsten crucible improve the quality and the rate of the finished products.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

A Brief Introduction of Tungsten Boat

- Details

- Category: Tungsten Information

- Published on Friday, 22 April 2016 16:44

Tungsten boat is also known as evaporated tungsten boat or coated tungsten boat. It is formed by tungsten sheet through high-pressure tungsten. Nowadays, tungsten boat is widely used in vacuum coating industry and sintering furnace and annealing boat industry. There are many specifications of tungsten boat and their shapes are different.

Tungsten boat is also known as evaporated tungsten boat or coated tungsten boat. It is formed by tungsten sheet through high-pressure tungsten. Nowadays, tungsten boat is widely used in vacuum coating industry and sintering furnace and annealing boat industry. There are many specifications of tungsten boat and their shapes are different.

Tungsten's unique properties, including a melting point of 3410° C, low vapor pressure at elevated temperatures and low coefficient of thermal expansion, make it of value in a variety of high temperature products and processes. First of all, the boat type component is made of tungsten metal. And then connect both ends of the component by wire, and put a low melting point metal in the middle of the concave position. Under the electrify condition, the temperature of tungsten boat would rise to about 2000 degrees, so that the metal can evaporate into gas and deposited on the surface of the workpiece.

Tungsten boat is also widely used as source for evaporation resistance. Its working methods is to make tungsten film into the shape of the boat firstly, then install it in two electrodes. Add materials in the center of tungsten boat, and then energize the electrodes slowly. After the current pass tungsten boat, the tungsten boat will give out the heating power. Low voltage and high current would transfer the heating power to the coating material, when quantity of heat of tungsten boat is higher than the melting point of the coating material, the material would obtain the sublimation or evaporate. But tungsten boat still has some limitations for vacuum coating. The film evaporated by tungsten boat has a low density, and there are a lot of materials cannot be deposited in this way. When tungsten boat evaporating and coating materials, the melting point of the material cannot higher than the melting point of tungsten boat.

Tungsten boat is also widely used in electronics industry, such as kinescope, mirror making, toys, household appliances, mobile phones, electrical enclosure. It has good characteristics for electrical conductivity, thermal conductivity, high temperature resistance, wear resistance, corrosion resistance. In addition, tungsten boat has a high melting point, low saturated vapor pressure and stable chemical properties, so it has been widely used as source for resistive evaporation in vacuum evaporation coating industry. Tungsten boat, as an essential part for vacuum coating equipment, the selection of tungsten boat determines the quality of the coating.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Bucking Bar Aviation Application

- Details

- Category: Tungsten Information

- Published on Friday, 22 April 2016 16:39

| Tungsten Bucking Bars Supplier: Chinatungsten Online buckingbar.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold Pen Holder

- Details

- Category: Tungsten Information

- Published on Friday, 22 April 2016 13:49

| Tungsten Gold Product Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold Plated Seal

- Details

- Category: Tungsten Information

- Published on Friday, 22 April 2016 13:45

| Tungsten Gold Seal Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Used in Gas Tungsten Arc Welding (GTAW)

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 18:15

Gas tungsten arc welding (GTAW) is an electric arc welding process that produces an arc between a nonconsumable tungsten electrode and the products to be welded. Besides, the weld is shielded from the shielding. GTAW has widely used range. On one hand, it can be used on ferrous and nonferrous metals welding, depending on the base metal, in all welding positions. On the other hand, it also can be used to weld thin or thick materials with or without a filler metal.

Using GTAW for thin or thick material welding is not the same. When welding thinner materials, edge joints, and flange, filler metals are not used. For thicker materials, an externally fed filler wire is generally used. The type of filler metal wire to be used is based on the chemical analysis of the base metal. The size of the filler metal wire depends on the thickness of the base metal, which usually dictates the welding current. Besides, the methods of operation for GTAW can be manual or automatic.

Tungsten electrode is an important part in GTAW welding. Tungsten has high temperature property, so it can be used in high temperature environment for long time without deformation. There are many tungsten electrode types including pure tungsten electrode, thoriated tungsten electrode and certiated tungsten electrode and so on. Besides, it also has different size, and the size of an electrode to be used is determined by the welding current required. Larger electrodes permit higher currents to be used. Smaller diameter electrodes may be used for welding thinner materials or while welding out of position.

Pure tungsten electrode used on nonferrous metals, such as aluminum and magnesium, and is typically used with a balled-end preparation on AC.

Thoriated tungsten electrode is the most widely used type and it usually use on carbon and stainless steel. It can be purchased with 1 or 2 percent thorium. The thoriated tungsten starts readily and maintains a stable arc. It has a greater resistance to contamination and will maintain a sharp point and will not break down as readily as pure tungsten.

Zirconiated tungsten electrode is welding with higher AC currents on nonferrous metals.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

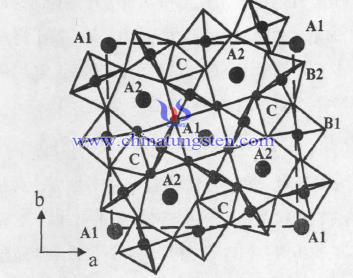

Tungsten Bronze Niobate Crystal I

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 18:10

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

2% Thorium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 18:06

2% thoriated tungsten electrode still have widely used, at least for DC welding. Because compared with other type tungsten electrodes it always has been the best all-around electrode. It lasts the longest, holds the sharpest point, and has the strongest arc and other advantages, so even it has radiation welders like to use it for TIG welding.

Compared pure tungsten electrode and thorium tungsten electrode welding aluminum on AC performance found pure tungsten electrode is softer and balls up easier for aluminum welding on AC, but it doesn’t handle heat as well. I preferred having electrodes that wouldn’t split at heat as opposed to one that balled up quickly. On the other hand, thorium tungsten electrodes stay sharp for so long and are so hard that there’s no way they can give off anything significantly harmful to breathe in during the welding process or to absorb while handling.

Besides, recently, some researchers released an article, “There is almost no release of radioactive material during arcing,” and “a welder holding an electrode for a whole year a very small fraction of the maximum permissible radiation dose, and it is concluded that the external radiation hazard is likely to be negligible.” They think that fears of radiation coming from the thoriated tungsten electrode had led the welding industry to look for alternatives electrode witch is unnecessary.

In fact, the only real danger in using 2 percent thoriated is inhalation of dust during grinding. Because during the grinding process, tungsten particles may produce with thoria on the surface and dust particles may be inhaled to cause harm TIG welders health. But these researchers insisted that the risk of cancer in due to thoria exposure is very low, since the exposure times to individuals are invariably small.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Darts JargonsⅡ

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 17:21

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Darts JargonsⅠ

- Details

- Category: Tungsten Information

- Published on Thursday, 21 April 2016 17:19

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com