How to Extract the Sapphire Ingot Seized in Tungsten Crucible?

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 18:33

Due to the different maturity of manufacturing process for tungsten crucible, there are some potential problems of the finished products which are difficult to find. Wolfram crucible is mainly formed by the tungsten powder molding which requires a lot of pressure during the pressing process. With the increase of inner stress of tungsten product, the inside of wolfram crucible would crack. Therefore, after the manufacturing process of the wolfram crucible, inside of it should be carefully examined. The followings will give a brief introduction of the steps for detecting internal defects of wolfram crucible.

Phased array ultrasonic testing equipment is the essential tool for detecting internal defects of wolfram crucible which is divided into three parts, choosing the best configuration of phased array ultrasonic testing equipment to test them respectively by ultrasonic detecting. It takes a short time to finish the examination only for10 minutes, and the operation is not complicated, with a high effect that can be applied to large-scale wolfram crucible producing.

Since wall of wolfram crucible is thin with a large area, it can be detected by double crystal probe in phased array ultrasonic testing. The structure of wolfram crucible bottom is relatively simple with a smooth surface, so inspector can use a high-frequency linear probe to detect it. The structure of the junction between wolfram crucible wall and bottom of the crucible is complex, deformation surface is relatively large, so inspector can use high sensitivity test block for its detection which can detect the smallest equivalent of 0.2mm hole.

Since wall of wolfram crucible is thin with a large area, it can be detected by double crystal probe in phased array ultrasonic testing. The structure of wolfram crucible bottom is relatively simple with a smooth surface, so inspector can use a high-frequency linear probe to detect it. The structure of the junction between wolfram crucible wall and bottom of the crucible is complex, deformation surface is relatively large, so inspector can use high sensitivity test block for its detection which can detect the smallest equivalent of 0.2mm hole.

Because of the particularity of the manufacturing process of the wolfram crucible, it would cause instable quality of wolfram crucible. The inside of wolfram crucible is easy to have cracks, holes and other defects. If it cannot be noticed in time which would cause further more severe crack during application or lead to a wolfram crucible burst, even result in serious accidents. Therefore, the detection of internal defects of finished wolfram crucible is necessary. Detecting by this method can ensure quality of product, and the detection result of the method is more intuitive, the cost of the process is low and it’s suitable for large-scale industrial production of wolfram crucible. Quality of wolfram crucible directly determines the quality of the follow-up work. Development of testing technology for nondestructive wolfram crucible has a great significance for industry. People should think highly of its applications.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Nuclear Island Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 18:31

Tungsten alloy nuclear island radiation shielding is widely used in nuclear power plants to shield radiation generated by the nuclear island. A nuclear power plant is a thermal power station in which the heat source is a nuclear reactor. Nuclear reactor, also known as nuclear island, is made up of nuclear steam supply system, containment spray system and auxiliary system (including equipment cooling water system, the reactor chamber and spent fuel cooling system, auxiliary feedwater system, ventilation and air conditioning systems, compressed air system and radioactive waste treatment systems). As is typical in all conventional thermal power plants the heat is used to generate steam which drives a steam turbine connected to an electric generator which produces electricity.

Tungsten alloy nuclear island radiation shielding is widely used in nuclear power plants to shield radiation generated by the nuclear island. A nuclear power plant is a thermal power station in which the heat source is a nuclear reactor. Nuclear reactor, also known as nuclear island, is made up of nuclear steam supply system, containment spray system and auxiliary system (including equipment cooling water system, the reactor chamber and spent fuel cooling system, auxiliary feedwater system, ventilation and air conditioning systems, compressed air system and radioactive waste treatment systems). As is typical in all conventional thermal power plants the heat is used to generate steam which drives a steam turbine connected to an electric generator which produces electricity.

When fission occurs,the nucleuses of the uranium, plutonium and other nuclear fuel nuclear split into two or more lower-mass atoms, releasing huge amounts of energy. The most common uranium fission is releasing two to four neutrons by bombarding uranium-235 with thermal neutrons, the neutrons then sequentially bombard other uranium 235 atoms, thereby forming a chain reaction. While the process of nuclear fission will produce nuclear radiation (such as neutron, gamma ray and other), which takes a toll on health by damaging normal mechanism in human body to cause cells to become cancerous,and severely impacting human important biochemical structure and function by breaking chemical bonds between molecules and atoms in the body. Nuclear radiation can also lead to fatigue, dizziness, insomnia, skin redness, ulceration, bleeding, hair loss, leukemia, vomiting, diarrhea and other symptoms, and increase disease incidence of cancer, distortion, hereditary disease. Therefore, the use of tungsten alloy nuclear island radiation shielding is a good choice to shield and absorb nuclear radiation produced by nuclear island, to avoid a significant impact arising from a radiation leak.

Since nuclear island is one of the main components of a nuclear power plant, tungsten alloy nuclear island radiation shielding is widely used in nuclear power plants. Tungsten alloy nuclear island radiation shielding has high density and excellent radiation shielding ability, so that can effectively absorb and shield radiation to reduce radiation hazards. And compared with conventional shielding materials (such as lead), tungsten alloy nuclear island radiation shielding is nontoxic and environmentally friendly material which does not release substances harmful to human health or the environment.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide for Hydrodesulfurization Catalyst Containing Molecular Sieve

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 18:22

With the increasing demand for diesel fuel, prolific diesel has become a development direction of the catalytic cracking process. LCO will bring a serious environmental pollution of combustion exhaust toxic gases (such as SOx) increasing, therefore, hydrodesulfurization catalyst can be used to reduce their emission of toxic gases. The introducing of molecular sieve in the hydrodesulfurization catalyst will help to improve the property of catalyst.

With the increasing demand for diesel fuel, prolific diesel has become a development direction of the catalytic cracking process. LCO will bring a serious environmental pollution of combustion exhaust toxic gases (such as SOx) increasing, therefore, hydrodesulfurization catalyst can be used to reduce their emission of toxic gases. The introducing of molecular sieve in the hydrodesulfurization catalyst will help to improve the property of catalyst.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Hydrodesulfurization Catalyst of Low-Grade Diesel Uses Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 18:19

Hydrodesulfurization has much attention in the hydrotreating technology; however, due to the high nitrogen heavy oil processing has become a trend, and exist of nitrides suppress the catalyst performance of deep hydrodesulfurization. Since the processing of nitrogen and offshore crude oil has a considerable proportion of China's oil refining industry, the development of low-grade nitrogen distillate deep hydrodesulfurization catalyst becomes very necessary.

Hydrodesulfurization has much attention in the hydrotreating technology; however, due to the high nitrogen heavy oil processing has become a trend, and exist of nitrides suppress the catalyst performance of deep hydrodesulfurization. Since the processing of nitrogen and offshore crude oil has a considerable proportion of China's oil refining industry, the development of low-grade nitrogen distillate deep hydrodesulfurization catalyst becomes very necessary.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

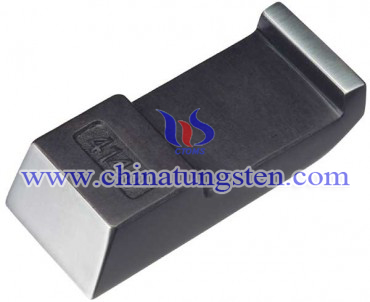

What is Tungsten Bucking Bar?

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 17:45

| Tungsten Bucking Bars Supplier: Chinatungsten Online buckingbar.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

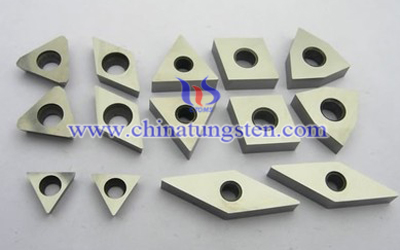

Copper Plating on Tungsten Carbide Cutting Tools (2/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 16:36

However, inside tungsten carbide usually contain some grease, which is not easily to be cleaned. And in the process of electro-deposition pretreatment, it will penetrate into plating solution, which resulting in the coating pan-point corrosion from the inside out, so that the final coating falls off. Compared with copper plating on other materials, tungsten carbide has higher requirements on degreasing. Commonly used methods of electrolytic degreasing, heat degreasing and organic solvent degreasing, and the heat degreasing is the best choice for tungsten carbide. It should be polished after degreasing, and remove the oxide layer on the surface and then wash by ionized water ultrasonic.

In pre-plating process, we use cyanide copper, and electroplating of copper sulfate usually used as the plating solution, the temperature controlled at about 20 ℃, air agitation, anode copper (copper) plating time is about 5-10min. Finally, we make a comprehensive assessment of coating from the appearance, the hardness and the bonding strength. From the appearance of the copper layer surface is smoother and surface roughness of less than 0.3μm. Compared with the coating without pretreatment or high-temperature degreasing, it has higher density and there is no peeling, cracking or shedding. The hardness of Cu plating layer on tungsten carbide can reach 216-219HV. Bonding strength test method can be divided into two types, one is heating, which heat the plated workpiece to 300℃ and hold 1h, quickly removed and placed in water at room temperature to observe whether the coating peeled or shed; the other is scribing, was 30 ° with the edge of the cutting carbide layer again designated as the side length of 1mm squares, and observation of the coating peeling off phenomenon.

In addition, the carbide deposition process for copper plating is a mechanical process of accumulation, due to copper and tungsten carbide WC and Co in the substantial absence of mutual penetration and dissolution, is a combination of mechanical way. After coating the hydrogen plasma treatment, the elements Cu and carbide matrix was dissolved in each other at the joint surface, diffusion, thereby forming an interface diffusion layer. The existence of this diffusion layer will make the combination of copper layer and cemented carbide substrate metallurgical bonded to shift from mechanical binding, thus combining the strength of the copper layer and the cemented carbide substrate has been significantly improved.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Copper Plating on Tungsten Carbide Cutting Tools (1/2)

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 16:18

Theoretically, deposit a diamond layer on tungsten carbide cutting tools by using CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition), which can be remarkably improve the properties of tungsten carbide. But the most common problem is the match of thermal performance and the binding force between cemented carbide substrate and the coating layer. So the researchers find that applying a layer of transition between the coated film and the cemented carbide substrate can significantly improve the performance of the film base. It refers to plating a metal layer on tungsten carbide cutting tools, which is the new attempt used electrodeposited layer as transition.

Cu has good wettability on diamond tools and in the CVD diamond deposition process, the Cu plating layer is almost not affected by the temperature, which is one of the ideal transition layer materials. The basic process of copper plating on tungsten carbide cutting tools: workpiece fabricating → pretreatment → washing → pre-plating → electroplating → washing. Since the most of the products are made of cemented carbide WC, TiC and other metal carbide and a binder composed of Co and prepared by powder metallurgy method, so there are some pores and defects between the grains, which means the corresponding pretreatment process for tungsten carbide coating layer is crucial. In order to remove the oxide layer on tungsten carbide surface, we usually choose pickling method. But this will lead to the shedding of small amount of Co on the surface and increase the pores on the surface. And the corresponding loss of Co binder role carbides will more easily expose to fall off so that the binding property of the coating is significantly reduced.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tartaric Acid Chemical Synthesis

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 14:37

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold Plated Bar for Real Estate

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 14:15

| Tungsten Gold Product Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold-Plated Necklace for Valentine's Day

- Details

- Category: Tungsten Information

- Published on Thursday, 28 April 2016 14:12

| Tungsten Gold Product Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com