Tungsten Alloy Shielding And Radiation Protection

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 18:06

Tungsten alloy shielding plays an important role in the field of radiation protection with its great radiation shielding effectiveness. Radiation protection, sometimes known as radiological protection, is defined by the International Atomic Energy Agency (IAEA) as "The protection of people from harmful effects of exposure to ionizing radiation, and the means for achieving this". Its main tasks are to protect the health and safety of personnel engaged in radiation work, public and their descendants, to protect the environment, and to promote the development of atomic energy industry. The main content of the radiation protection consists of standards for radiation protection, radiation protection evaluation, radiation dosimetry, technology of radiation protection and radiation protection management. The factors of radiation protection include time, distance and shielding. Shielding means set a shielding material between the radiation source and the body to attenuate the intensity of radiation, thereby reducing the radiation levels.

Tungsten alloy shielding plays an important role in the field of radiation protection with its great radiation shielding effectiveness. Radiation protection, sometimes known as radiological protection, is defined by the International Atomic Energy Agency (IAEA) as "The protection of people from harmful effects of exposure to ionizing radiation, and the means for achieving this". Its main tasks are to protect the health and safety of personnel engaged in radiation work, public and their descendants, to protect the environment, and to promote the development of atomic energy industry. The main content of the radiation protection consists of standards for radiation protection, radiation protection evaluation, radiation dosimetry, technology of radiation protection and radiation protection management. The factors of radiation protection include time, distance and shielding. Shielding means set a shielding material between the radiation source and the body to attenuate the intensity of radiation, thereby reducing the radiation levels.

Radiation is often classified as either ionizing radiation or non- ionizing radiation depending on the energy of the radiated particles. Ionizing radiation is radiation that carries enough energy to free electrons from atoms or molecules, thereby ionizing them. The common ionizing radiations are α particles, β particles, protons, neutrons, X rays, and γ rays. While non- ionizing radiation has lower energy than ionizing radiation and does not ionize atoms or molecules. For people involved with the radiation work, radiation hazards will occur when not take protective measures to protect body from being irradiated with a dose of radiation. Radiation can cause radiation sickness, making lesions in almost all human organs and systems (including the nervous system, blood-forming organs and the digestive system). And it can also cause acute radiation injury due to a certain dose of radiation exposition in a short time and chronic radiation injury whose irradiation time is longer. Chronic radiation injury will lead to skin damage, weakened immunity, impaired fertility and so on.

There are a many types of tungsten alloy shielding, including tungsten alloy shielding tank, tungsten alloy shielding container, tungsten alloy shielding cover, tungsten alloy shielding shell. Because the radiation shielding properties of a metal material increases with the increasing of its density, and tungsten alloy has great density, tungsten alloy shielding therefore has excellent radiation shielding capability and absorption capacity. Putting a tungsten alloy shielding between the body and the radiation source can effectively reduce the radiation intensity to avoid radiation damage.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

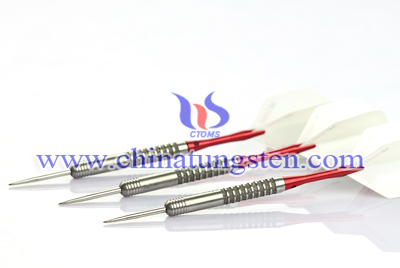

Why Choose Tungsten Darts?

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:35

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Killer Tungsten Darts Rules

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:30

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Hydrodesulfurization Catalyst Containing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:26

The acid value, total content of sulfur and mercaptan is important indicator of light oil. Mercaptan itself is corrosive, also makes oil noxious odors, and the oil quality and stability are reduced, and therefore, the removal or conversion of mercaptans has become necessary. Currently, there are three types of deodorization method commonly used, which are acid-base electrochemical refining, oxidation sweetening and hydrogenation process.

The acid value, total content of sulfur and mercaptan is important indicator of light oil. Mercaptan itself is corrosive, also makes oil noxious odors, and the oil quality and stability are reduced, and therefore, the removal or conversion of mercaptans has become necessary. Currently, there are three types of deodorization method commonly used, which are acid-base electrochemical refining, oxidation sweetening and hydrogenation process.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Fine-grain Liner Fabricating Process (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:12

In these composite materials, tungsten copper is the most ideal material for the liner. Tungsten copper alloy is Cu difference between two kinds of physical and chemical properties of W and face-centered cubic structure of the body-centered cubic structure is neither large nor the formation of pseudo alloy intermetallic compounds. It not only has high hardness, high strength, high density, low thermal expansion coefficient and excellent abrasion resistance of W and also has plasticity and excellent electrical and thermal conductivity of Cu. Tungsten jet head with a higher speed, when penetrating armor can shorten the time through, thereby facilitating against reactive armor. But it is brittle and the powder adhesion is poor, the added copper powder with good ductility can contribute to the shaping process and improve the jet stability, avoid breaking.

However, tungsten copper alloy material prepared by the conventional powder metallurgy method, since good metal powder flowability and there are many random factors hard to be controlled in mechanized packing, press-forming and other processes, it will cause some problems, such as coarse grains, poor uniformity and density distribution, depth fluctuations, which can not meet the requirements of the weapon. In addition, the tungsten copper composite liner is very sensitive to the height of burst; under the big height of burst the penetration depth has a rapid decline and the ideal height of burst is 3 times than the diameter.

This is also the commonness of composite liner, which means under small height of burst, the armor depth increase by 30% than the pure copper liner, but under big height of burst it is difficult to obtain the good jet ductility. For the reason, the researchers have proposed a kind of new process that spray pyrolysis milling – wet milling – liquid-phase sintering to fabricate tungsten copper liner. Wherein the spray pyrolysis milling precipitated nano-scale tungsten phase approximately spherical and uniformly distributed on the Cu substrate, improving both activity; wet ball milling can reduce the powder oxidation and prevent metal grains from gathering and growing; liquid-phase sintering is beneficial for higher densification and better uniformity.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Fine-grain Liner Fabricating Process (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:10

With the development of military modernization, anti-missile capability has been greatly improved in a number of armored tanks, armored vehicles and so on. As it is now already have a high anti-missile capability reactive armor scaly, lean axle loads armor, ceramic composite armor, explosive reactive armor, which gives the more severe challenges to anti-armor weapons. The combination of shaped charge and precision guidance is the most effective anti-armor weapon, and the liner is key component of the shaped charge, whose performance will directly affect the jet armor penetration capability and stability.

So the new material for liner has become the hotspot of related researchers and scholars. Research focused on how to enhance the ductility of the material, increase the density of the material and refine the grain structure. The ductility enhancement helps form long projectile, thereby increasing the penetration depth; the density increases will enhance the impact force; refine the grain structure is conducive to increase the length of the jet. Due to the single component, traditional liner is not sufficient to meet the performance requirements today. With further research, the liner made by composite material appears. It is combining with a variety of different properties of metals or alloys to meet the design requirements liner. Compared with single metal liner, it has many advantages, such as high energy conversion efficiency, high energy efficiency, more reasonable absorption mechanism and excellent armor performance, which is the inevitable trend of liner development.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide for Hydrodesulfurization and Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:04

Currently, scientific research and practical results in the hydrotreating catalyst in and abroad mainly be: improving catalyst hydrogenation activity and life by using new type of composite carrier, and modulation of the active ingredient, introducing appropriate additives and metal complexing agent. In the oil refining field, Y-Al2O3 is the preferred carrier for the hydrotreating catalyst, which is also most widely used of catalyst carrier currently.

Currently, scientific research and practical results in the hydrotreating catalyst in and abroad mainly be: improving catalyst hydrogenation activity and life by using new type of composite carrier, and modulation of the active ingredient, introducing appropriate additives and metal complexing agent. In the oil refining field, Y-Al2O3 is the preferred carrier for the hydrotreating catalyst, which is also most widely used of catalyst carrier currently.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Electrode Production Technology - Swaging Process

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 16:52

Obtained tungsten billet by powder metallurgy method, should to go through swaging, drawing, straightening, polishing and other follow-up process, which can be processed into various size and length tungsten electrode. Swaging, also known as rotary forging, is forging a special forged. Using swaging to process plastic working on tungsten electrode can reduce electrode‘s diameter and increase the length, while improving the physical and chemical properties of the electrode, to improve the plasticity and other properties of the electrodes. Swaging process operation by swaging machine, through high-speed rotation, drives rollers and swaging dies to operate and makes swaging die to linearly reciprocate, to forge tungsten billet. In the plastic working is generally subjected to initial deformation, recrystallization annealing and second return deformation.

In the process of swaging, to process deformation on tungsten billet easily lead to electrode inside and outside organization uneven. In general, the degree of surface deformation is large and center deformation is small, so the stress of electrode distribution is also not uniformly. Therefor, between the first and second deformation to process recrystallization annealing can adjust the electrode internal fibrous structure, thereby improving the processing performance of the electrode. Swaging process is the first deformation of the electrode, and it plays an important role for successful subsequent processing. So the reasonable swaging process can produce beneficial to plastic deformation microstructure. In addition, during swaging process, the processing temperature and processing passes is an important factor of swaging effect, so should be strictly controlled.

In the swaging process, the tungsten bar in stress state is in favor of deformation processing. In addition, small passes deformation, high forging frequency can make tungsten bar to distort at small deformation force, but the swaging process required more molds. Due to the small amount of deformation always starts from the surface of tungsten bar, so easy to make tungsten electrode uneven distribution of stress and deformation, resulting in defects in subsequent processing.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Tungsten Electrodes and Metal Halide

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 16:43

Metal halide is kind of discharge lamp, and it can produce arc in the mixed steam of mercury and rare metal halide. Besides, it is a daylight colour new energy-saving light source. Metal halide having a high luminous efficiency, good color, long life and other advantages, is widely as indoor lighting used in stadiums, exhibition centers, shopping malls, industrial buildings, streets and squares, railway stations, docks and other places

Tungsten electrode is usually as electrode material used in metal halide lamp, having a certain impact on the performance of metal halide. So to produce high quality tungsten electrodes in favor of extend metal halide lamps’ application and prolong its service life. Earlier, people often used pure tungsten electrode and thorium tungsten electrode as tungsten material in metal halide, but thorium tungsten electrode has radioaction and pure tungsten electrodes has poor performance, so many manufacturers began to study different rare earth tungsten electrodes’ performance in the metal halide.

To further study metal halide’s electrode materials found using liquid-solid mixing method for raw materials mixing, and then using the powder metallurgy method to obtain tungsten billet, finally after swaging, annealing, straightening and other processes can produce excellent performance electrode material. Observing the performance of different rare earth tungsten electrodes used in metal halide discovery found, yttrium and cerium tungsten electrode color temperature, luminous flux and luminous efficiency is low. But thorium tungsten electrode and dysprosium tungsten electrode has higher color temperature and, luminous flux and luminous efficiency. Among them, lanthanum tungsten has minimum color rendering index, and dysprosium tungsten has highest color rendering index. Comparison the application effect of different rare earth in metal halide found dysprosium tungsten electrode and dysprosium yttrium tungsten electrodes has similar lighting parameters with thorium tungsten electrode. In addition, the starting, splash and corrosion resistance performance of dysprosium tungsten and yttrium dysprosium tungsten electrodes can reach a similar level to thorium tungsten electrode.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tantalum Tungsten Bronze

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 15:01

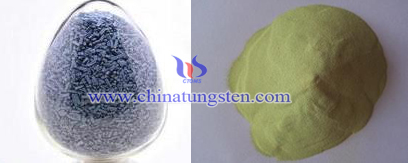

Tungsten oxide is a kind of transition metal oxide, its special property makes it be widely used in electrochromic device, gas sensor, separating material and so on. W ion in tungsten bronze belongs to changeable valence state, when introduce transition metal into crystalline structure, valence state of W transits between W6+,W5+ and W4+, unstable oxygen valance will form in lattice, surface of material will show defects. As a result, tungsten oxide shows special physical and chemical property. Tantalum belongs to transition metal which can be used as electrode material. Also dimension of Ta5+ is small and active, we can judge that doping tantalum can have great influence on its electric chemical property.

Preparation

1. Weighing 2g Na2WO4.2H2O in reaction still with politef lining. Add in redistilled water, magnetic stirring and dissolving.

2. Adding a certain amount of 3 mol/L hydrochloric acid, control the whole reaction system pH lower than 1.5. Adding 0.05 mol/L TaCl5 and 0.5 mol/L NH4(SO4)2, stirring for 2hours and sealed the reaction still.

3. Heating it for 48h under 170 ℃, wash the reaction producer with distilled water to neutral, then put it in -40℃ lyophilizer.

Lead tantalum into hexagonal tungsten oxide structure by hydrothermal method, nano wire structure TaxWO3 is obtained, the sample is even and with high purity. When Ta and W ratio in TaxWO3 is 0.04, it reaches the settled limiting value of tantalum doping in tungsten oxide. Doping low valance state and big diameter tantalum ion into tungsten oxide, its cell parameters get affected, lattice is changed, oxygen valence on the surface of material ratio enlarged, the electron transition ability decreases, the catalytic property of material improves. Under acid condition, reduction of TaxWO3 for H+ is more stable, it has potential application in fuel cell field.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com