Hydrodesulfurization Catalyst Containing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 29 April 2016 17:26

The acid value, total content of sulfur and mercaptan is important indicator of light oil. Mercaptan itself is corrosive, also makes oil noxious odors, and the oil quality and stability are reduced, and therefore, the removal or conversion of mercaptans has become necessary. Currently, there are three types of deodorization method commonly used, which are acid-base electrochemical refining, oxidation sweetening and hydrogenation process.

The acid value, total content of sulfur and mercaptan is important indicator of light oil. Mercaptan itself is corrosive, also makes oil noxious odors, and the oil quality and stability are reduced, and therefore, the removal or conversion of mercaptans has become necessary. Currently, there are three types of deodorization method commonly used, which are acid-base electrochemical refining, oxidation sweetening and hydrogenation process.

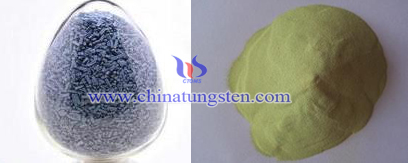

Hydrodesulfurization catalyst plays a very important role in the hydrogenation process, its cost directly depend the operating costs of the entire hydrogenation process. Most of the catalysts have high metal content, which makes the cost relatively high. Studies have shown that, through the introduction of tungsten trioxide, nickel and cobalt oxide as the main active components, and adjust their ratio which can significantly improve low-temperature desulfurization activity of the catalyst, by the same time reducing metal content.

A preparing method for light oil hydrodesulfurization catalyst containing tungsten trioxide with low metal content and cost, and high activity at low temperature is as follows:

1. The alumina precursor (quasi-boehmite, gibbsite, etc.) went though molding, drying, and then calcined under the air or steam atmosphere at 500~700℃ for 1-6 hours to obtain alumina carrier;

2. Dipping aluminum oxide in the aqueous solution of tungsten and nickel compound, then dried and calcined. Wherein tungsten trioxide and nickel oxide respectively occupy 4%~10% and 2% ~4% of the total mass of final catalyst;

3. Impregnating the product of step 2 by an aqueous solution of cobalt compound, and calcining under 150~250℃ for 2~4 hours to obtain the final hydrodesulfurization catalyst containing with tungsten trioxide. Wherein the amount of cobalt compound is ensuring cobalt oxide takes 0.02 to 0.5% of the total mass of final catalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com