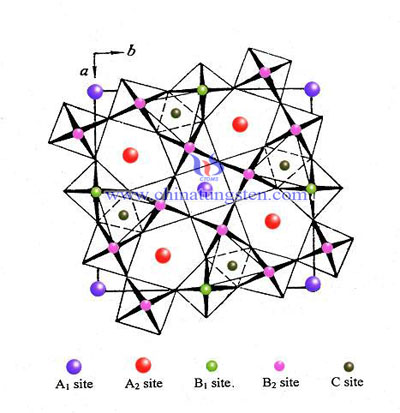

Tungsten Bronze Introduction

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 17:05

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Darts Popular Factors

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 17:05

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

How to Repair IG Tungsten Filament of GC-MS?

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 17:00

One of the most important methods to analyze the structural of organic compound is organicmass spectrometry (OMS), thanks to its fast speed, accurate property and molecular weight and other excellent features, OMS can directly analyze formula weight and structure of various organic compounds of a mixture. Mass spectrometry is an analytical method to measure the proportion of ion charge (the charge - mass ratio) which is a plot of the ion signal as a function of the mass-to-charge ratio. These spectra are used to determine the elemental or isotopic signature of a sample, the masses of particles and of molecules, and to elucidate the chemical structures of molecules, such as peptides and other chemical compounds. Therefore, gas chromatography - mass spectrometry (GC-MS) has been widely used in organic chemistry, organic geochemistry, biochemistry, food chemical, petrochemical, medical and health, environmental science and other fields. HP5890-5971 GC-MS is a high-performance analytical instrument. In normal using, the life time of ion gun wolfram filament can last for one year or longer. However, if the sample was not handled adequately, moisture content is too high, or injection quantity is too much which will greatly shorten the life time of the IG tungsten filament. If use the imported filament, then frequent replacement would cause greater economic losses and burdens. Thus, repair the IG tungsten filament of GC-MS can not only reduce costs, but also extend the life time of the filament which plays a role in protecting the environment.

First of all, cleaning the filament frame. Material should be cleaned with absolute methanol as the solvent, in the condition of ultrasound cleaning it for 5 minutes, then drying it at the temperature of 105 ℃. The next step is to wash the directly heated cathode. Oil should be cleaned with phosphoric acid cleaning agent, then rinse it with water, ultrasound cleaning it with absolute methanol for 3 minutes and finally drying it at a temperature of 105 ℃. The third step is to anneal the filaments. The fourth step is spot welding which is a high-speed, economical connection method. The final step is to clean the frame of electron-tube heater again, washing the excess flux.

Its relative abundance, quality and abundance are similar with the original filaments by this method to repair an ion source W-filament.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

How to Change Electron Gun Filament of Precise Accelerator?

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 16:56

Under a long term using of Precise accelerator, the filament will gradually aging, resulting in decline of its measurement rate. Therefore, it is time to increase the filament voltage and adjust the transmit power. If the measurement rate is too low to be measured, electron gun filament should be changed, after changing, operators should adjust the automatic frequency control (AFC) and gun servo.

At the beginning of changing the electron gun tungsten filament, rotating gantry should be adjust to 108 °, and then cut off the ion pump power supply. Plastic bag should be aerated with dry and clean nitrogen gas and tied it at the interface of high vacuum repair valve. On the basis of direction of the mark on the valve body, open high vacuum valve slowly, and then the nitrogen would be inhaled gradually. When the pressure of nitrogen of system is balance, turn off the high vacuum valve repair. Remove the outer casing housing of gun filament (pay attention to make red dot be directed at 0) and remove its subassembly. The process of the replacement of the gun filament and seals should be in a clean and dry air. Engineers should wear gloves and masks. In addition, tools can be used after cleaning by absolute ethyl alcohol in order to avoid the dust into the high vacuum system to influence beam stability and life of the filament. Finally, reinstall the gun filament subassembly and outer casing housing.

At the beginning of changing the electron gun tungsten filament, rotating gantry should be adjust to 108 °, and then cut off the ion pump power supply. Plastic bag should be aerated with dry and clean nitrogen gas and tied it at the interface of high vacuum repair valve. On the basis of direction of the mark on the valve body, open high vacuum valve slowly, and then the nitrogen would be inhaled gradually. When the pressure of nitrogen of system is balance, turn off the high vacuum valve repair. Remove the outer casing housing of gun filament (pay attention to make red dot be directed at 0) and remove its subassembly. The process of the replacement of the gun filament and seals should be in a clean and dry air. Engineers should wear gloves and masks. In addition, tools can be used after cleaning by absolute ethyl alcohol in order to avoid the dust into the high vacuum system to influence beam stability and life of the filament. Finally, reinstall the gun filament subassembly and outer casing housing.

The next step is to adjust the AFC. When the 6MV X-ray light is stable and sends light, set the Gun Man / Auto as manual and set the Phase Auto / Man as manual. Input the Tuner ctrl. Part4 value to Part1, adjust tuner ctrl so that its output is maximum, adjust Lp phase ctrl to make Comp Phase value is 0, set the value Lp phase posn Lp as phase ctrl.

Finally, adjust the servo gun. Before doing it, operators should ensure that the automatic frequency control has been completed adjusted, on this basis, and then adjust the X-ray and each file of electron beam individually. When adjusting the X-ray gun servo, under the dosage rate of 400MU / min, set the i181 Gun auto as manual. adjust i327 Gun I ctrl to make its output become maximum, change the i181 gun auto to automatism, adjusting i186 hump gain to make the part 4 of i327 Gun I ctrl the same as part1. Replacement of the electron gun filament is complicated and fussy, engineers must grasp the replacement process in every detail to ensure the stable operation of the accelerator.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

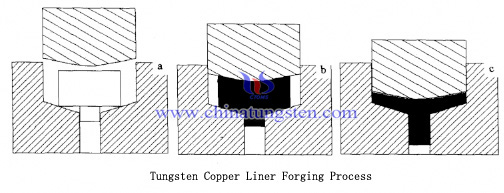

Tungsten Copper EFP Liner Manufacturing Process (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 16:51

By comparison, tungsten copper W-Cu system combines high hardness, high density, high strength and excellent chemical properties of W and excellent thermal conductivity of and plasticity of Cu. Since there is a big difference between W and Cu (W-3410℃,Cu-1083℃), After the explosion of copper is evaporated leaving a high hardness, high density hard phase tungsten, compared to copper Liner armor penetration depth can be increased by nearly 30%. Therefore, tungsten copper EFP liner has a broad application prospect in the future. Ordinary tungsten powder, copper powder and ultra-fine tungsten-copper composite powder prepared tungsten copper EFP Liner and its performance was compared. Wherein ultrafine tungsten copper composite powder is prepared by using spray pyrolysis, it uses a proportion of copper nitrate and ammonium metatungstate dissolved in distilled water into the mixed solution, and then the pressure centrifugal spray drier precursor powders, the precursor powder is then placed in roasting reduction furnace. Finally, wet ground and placed in a ball mill reduction in the reduction furnace, ultra-fine tungsten-copper composite powder particle size is formed between 100-300nm.

After the tungsten copper rod made of tungsten copper EFP started liner blank forging, which blank deformation has three steps: 1. upsetting the blank in the mold, in this process the blank upper and lower parts deformation occurs first, and upper and lower portions of the pores gradually become less under the influence of compressive stress, density increases, increasing the contact area with the punch, friction force increases, under the action of the metal tensile stress generated lateral flow; 2. metal flows hindered by the mold wall and it will flow along with the hole of the mold bottom, and in the process the pores reduces and the density increases; finally, when the metal flow to the ejector rod will enter the multi-pressure stage, mainly through its hydrostatic pressure to eliminate rough pores, so the effect is not significant.

In addition, in the process of tungsten copper EFP liner blank forging, there are two ways of deformation of the matrix material, one is only copper phase deformation, deformation does not occur with tungsten and tungsten particles along the direction of deformed copper matrix flow was streamlined distribution; the other one is both of Cu and W phase have deformation and form fibrous structure. In order to ensure that the final density, tensile strength and elongation to achieve the desired requirements, we should make a reasonable design for tungsten copper EFP liner shape and have sufficient deformation.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper EFP Liner Manufacturing Process (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 16:49

Tungsten copper EFP liner, EFP is abbreviation of Explosively Formed Penetrator, which is “explosively formed piercing warhead” or “self forging fragmentation warhead”, some countries also known as P Charge (Projectile Charge), Misznay-Schardin Charge and mass shaped charge and so on. A typical EFP warhead consists of a metal liner, housing, as well as booster explosive components consisting of a series, there is usually a cover for drug and explosive type of pressure ring assembly is secured. It relies on the projectiles with high kinetic energy to armor, compared with conventional HEAT projectile with charge jet, in the high explosive detonation, the energy generated by the blast occurred folded by deforming Liner and get high speed, because the speed difference the presence of eventually forming a penetrator.

The explosively formed projectile EFP here we are introducing is also one of a kind shaped charge, it uses more than 120 ° cone angle hemispherical cap or hyperbolic Liner conduct charge. After the explosion, tungsten copper liner extruded by great load and after flip closed to form explosively formed projectile. And it has many advantages, such as less interferes to reactive armor, great penetration aftereffect and be insensitive to the height of burst. So the capacity of armor and penetrate highly depends on the materials of liner.

The conventional materials of liner include iron, copper, depleted uranium, tantalum and so on. Pure iron and pure copper has excellent plasticity, but their density is lower, which reduces the kinetic energy of projectile formed and the penetration force of the target material; the depleted uranium has a high density and plasticity, can greatly enhance the strength and armor-piercing Immunity range of thousands of degrees of high temperature burning effect, but the depleted uranium is still radioactive material, and it is harmful to human health; tantalum element is a kind of rare-earth element, it has the ability of penetration is much greater than copper and iron, but its high cost problems that have hindered the promotion of the use of the important factors.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Practice Methods of Tungsten DartsⅡ

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 16:39

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Practice Methods of Tungsten DartsⅠ

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 16:37

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Shielding For Radiation Preservation

- Details

- Category: Tungsten Information

- Published on Friday, 06 May 2016 15:50

Radiation processing is a promising technology that has been widely applied in the processing of harvested agricultural products. Radiation preservation, which based on the radiation processing, is a method that uses ionizing radiation (mainly the γ-ray produced by radioactive isotope Co-60, Cs-137 and electron beams or X- rays generated by an electron accelerator) to irradiate fruits, vegetables and other agricultural products, making water molecules inside agricultural products interact with other substances, thereby killing microorganisms and pests, inhibiting germination and extending the shelf-life, achieving the aim of keeping fruits and vegetables in storage fresh. By 1986, 33 countries (including the former Soviet Union, the United States, Japan, etc.) approved or provisionally approved the commercialization application of 19 kinds of food products which are kept fresh by radiation. And nearly more than 20 commercial radiators have been used for radiation preservation and more than 70 kinds of food products have been allowed to extend their storage period or shelf life and kill pests or bacteria in them by radiation throughout the world.

Radiation processing is a promising technology that has been widely applied in the processing of harvested agricultural products. Radiation preservation, which based on the radiation processing, is a method that uses ionizing radiation (mainly the γ-ray produced by radioactive isotope Co-60, Cs-137 and electron beams or X- rays generated by an electron accelerator) to irradiate fruits, vegetables and other agricultural products, making water molecules inside agricultural products interact with other substances, thereby killing microorganisms and pests, inhibiting germination and extending the shelf-life, achieving the aim of keeping fruits and vegetables in storage fresh. By 1986, 33 countries (including the former Soviet Union, the United States, Japan, etc.) approved or provisionally approved the commercialization application of 19 kinds of food products which are kept fresh by radiation. And nearly more than 20 commercial radiators have been used for radiation preservation and more than 70 kinds of food products have been allowed to extend their storage period or shelf life and kill pests or bacteria in them by radiation throughout the world.

Radiation preservation works by radiation to kill pathogenic microorganisms or harmful insects hidden in fruits and vegetables, or inhibiting their growth or causing infertility or fertility decline, thus delaying the maturation process of the fruits and vegetables to maintain freshness. Radiation preservation has the advantages of reducing losses of agricultural products, eliminating the root causes of rot and spoilage, energy saving and wide practicability. Because the γ-rays and X-rays used in radiation preservation technology have certain harm on human, and can damage the process of normal cell division leading to cancers, can cause bleeding gums, skin erythema, decreased immunity, hair loss and other diseases. Thus, related personnel should pay attention to the question about radiation protection when in dealing with fruits and vegetables and other agricultural products by radiation .Tungsten alloy shielding is the best choice.

Tungsten is a rare-nonferrous metal with high melting point, high density, high hardness and good creep resistance, thermal conductivity and electrical conductivity. While tungsten alloy is a tungsten-based alloy that adds other elements. The feature of high-density which tungsten alloy shielding has makes it has good radiation absorption and radiation shielding performance. Compared with conventional shielding materials (such as lead), tungsten alloy shielding shows the characteristics of more environmentally friendly. Lead and its compounds are toxic to human tissues, long-term use of it will lead to poisoning, but tungsten alloy shielding does not produce toxic radioactive substances, neither endanger human, nor pollute the environment. In addition, tungsten alloy shielding is easy to process, and tungsten is abundant.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Types Of Radiation

- Details

- Category: Tungsten Information

- Published on Thursday, 05 May 2016 18:43

With the development and application of science and technology and the widely use of a variety of electronic devices, people has not been unfamiliar to the term of "radiation" any longer. According to its energy level and the ability to ionize substance, radiation can be divided into ionizing radiation and non-ionizing radiation. Ionizing radiation is radiation that carries enough energy to free electrons from atoms or molecules, thereby ionizing them. It is made up of energetic subatomic particles, ions or atoms moving at high speeds and electromagnetic waves on the high-energy end of the electromagnetic spectrum. While non-ionizing radiation refers to any type of radiation that does not carry enough energy to ionize atoms or molecules, including low-frequency electromagnetic radiation, ultraviolet light, red inside, microwaves and radio waves. Alpha, beta, γ, X radiation, neutron radiation and high-frequency electromagnetic radiation are ionizing radiation.

With the development and application of science and technology and the widely use of a variety of electronic devices, people has not been unfamiliar to the term of "radiation" any longer. According to its energy level and the ability to ionize substance, radiation can be divided into ionizing radiation and non-ionizing radiation. Ionizing radiation is radiation that carries enough energy to free electrons from atoms or molecules, thereby ionizing them. It is made up of energetic subatomic particles, ions or atoms moving at high speeds and electromagnetic waves on the high-energy end of the electromagnetic spectrum. While non-ionizing radiation refers to any type of radiation that does not carry enough energy to ionize atoms or molecules, including low-frequency electromagnetic radiation, ultraviolet light, red inside, microwaves and radio waves. Alpha, beta, γ, X radiation, neutron radiation and high-frequency electromagnetic radiation are ionizing radiation.

Alpha particle consists of two protons and two neutrons bound together into a particle identical to a helium nucleus. It is a highly ionizing form of particle radiation which can be emitted by various radioactive substances (such as radium); the ionization value of β particle — a high-energy, high-speed electrons or positrons emitted by certain types of radioactive nuclei — is much smaller than α particle, but penetration ability is more stronger; γ-ray that has a wavelength less than 0.01 Å can released by the energy level transition, owing to its strong penetration, it has been used for industrial flaw detection or pipeline automatic control, as well as for medical tumor treatment; the wavelength of X ray is between ultraviolet and γ-ray, X-ray has great penetrating, ionization and fluorescence effects, which can be used for diagnostic medical imaging, medical fluoroscopy and non destructive testing; while neutron radiation can be produced by nuclear fission and nuclear fusion m.

Radiation can accelerate the decline and fall of cells, inhibit the generation of new cells, and cause hematopoietic organ failure and damage to the digestive system, central nervous system damage, etc. It can also cause radiation sickness, cancer, leukemia, cataracts and other diseases. Due to the dangers of radiation, radiation protection also attracts people’s attention, tungsten alloy shielding is one of the means. Placing tungsten alloy shielding with high radiation shielding effectiveness between the radiation and the human body or around radiation source, can effectively weaken the intensity of the radiation to avoid human being exposure to radiation damage, so that the body can be away from all kinds of radiation sickness. In addition, tungsten alloy is nontoxic and environmentally-friendly metal alloy, does not release toxic substances, so do not worry about the question of the environment pollution or human health.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com