Tungsten Bronze PZT Actuator Hysteresis Characteristics

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 18:02

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

A Brief Introduction of Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 17:39

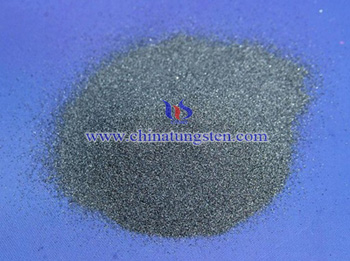

Tungsten granule is a flux which is major applied to the high frequency infrared carbon and sulfur analyzer. Therefore, tungsten granule also known as tungsten flux or pure tungsten flux. After processing the tungsten metal into some tiny particles, tungsten flux can be produced. The purity of tungsten granule is very high, it can reach more than 99.95%. And the size of tungsten granule is 20-40 mesh. As a flux, tungsten granule has good fluxing effectiveness and a stability analysis. Tungsten granule has been widely applied to the electronic chemical industry.

The shape of tungsten granule is polyhedral particles with bright gray color. Tungsten granule is mainly made of above tungsten. Tungsten is easily oxidized into tungsten oxide which belongs to acidity element and benefits the release of carbon dioxide and sulfur dioxide. In 1781, tungsten is a kind of mineral which was found by the Swedish chemist and mineralogist named Clance Tate.

There exist very low impurity elements in tungsten granule. The carbon element is less than 0.0008%, the sulfur element is less than 0.0005%, and an oxygen element is less than 0.05%. Therefore, tungsten granule has a high purity. In the most cases, tungsten granule is packed 1000g a bottle. The weight would be different due to the different specifications.

With the rapid development of modern science and technology, according to the demand of the production process, tungsten granule is widely applied to metallurgy, welding, and other analytical testing process. Nowadays, tungsten flux is the most indispensable fluxing materials for Infrared analyzer or other analyzers to measure the content of carbon and sulfur. It would release about 195.8 kcal / mol of heat when it start to oxidized with oxygen under a temperature greater than 650 ℃. Therefore, it has a strong fluxing effectiveness.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Applications of Tungsten Granule

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 17:26

The main application of tungsten granule is to analyze the Infrared carbon and sulfur oxide. The tungsten granule can also be applied to analyze the content of the carbon and sulfur of iron or metal. As a flux, the characteristic of tungsten granule is stability, and it can also reduce the melting point of comburent or promote the release of carbon and sulfur.

Tungsten particles can also be used as an additive in Infrared carbon and sulfur analyzer. The characteristic of Infrared carbon and sulfur analyzer is a high instantaneous heating, besides, the speed of its reaction is fast. Tungsten granule not only acts as a flux, but also adjusts the PH (potential of hydrogen) of the medium. In addition, the tungsten granule also has many other effects, such as stirring and anti-jamming. The tungsten granule of Infrared carbon and sulfur analyzer can make the values of carbon and sulfur more accuracy, so most Infrared carbon and sulfur analyzer consider tungsten granule as an additive.

With the rapid development of tungsten industry, tungsten granule industry has been widely applied in many fields. However, there are still many problems in applications of tungsten granule. For example, the utilization of tungsten granule resources is lower, and the irrational exploitation of tungsten would cause the ecological environment pollution. To solve these problems, enterprises should improve the recycling of tungsten granule.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Darts Casting Skills

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 17:21

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Advantages of Tungsten Darts Sport

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 17:16

| Tungsten Darts Supplier: Chinatungsten Online www.chinadart.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Features of Tungsten Granule in Infrared Carbon Sulfur Analyzer

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 17:09

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Fiber-structure Tungsten Copper Contact (2/2)

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 16:29

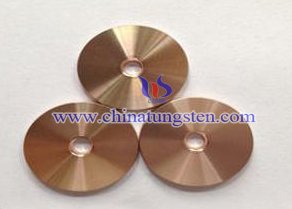

Copper in the molten state infiltrated in pores of tungsten skeleton by capillary forces, thereby connected to each other and form a dense material integrally. The advantage of using this method is that tungsten wire can distribute uniformly and copper wire can effectively induce. Since the most difficult to achieve tungsten copper contact with fiber-structure is how to make the fibers uniformly distribute in the matrix, whose distribution will affect the final properties directly. The weaving process can control tungsten wire to adjust the spacing between fibers. In addition, the distribution of copper wire at a high temperature infiltration, which presents the liquid copper supplement, under the action of surface tension, integration can reduce the surface area, prompting tungsten copper contact materials densification.

Tungsten wire diameter, infiltrated temperature and time all have an effect on the process. It uses tungsten fiber to take place of tungsten powder of conventional PM. Too large granularity of tungsten powder will have segregation and appear large area Cu-rich region, the binding force between the tungsten particles is also poor; too small granularity will prone to accumulate, leading to difficult to form a passage between the capillary and even hinder the formation of closed-cell infiltration were, so that the anti-arc erosion capacity decreases dramatically.

Fiber-structure has straight route so its density is higher after infiltration. But with the decreasing fiber diameter, it easily to form when copper was infiltrated pointed or wedge-shaped space, and solidification resistance is also large so that the defect forms. In addition, infiltration temperature has an optimum range, below the temperature which the sintered skeleton strength decreases, and the extension of sintering time, decrease the efficiency and increase energy consumption; the high temperature which the copper was in favor of lowering the viscosity of infiltration, but on the other hand the surface tension of liquid copper is reduced, and has an adverse effect on infiltration.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Fiber-structure Tungsten Copper Contact (1/2)

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 16:28

Tungsten copper is a psudoalloy, which is composed of two kinds of immiscible and has a great difference in physical and chemical properties metals. Since it has both advantages of W and Cu (high hardness, high strength, excellent corrosion resistance of W, excellent electrical and thermal conductivity of Cu) so that it has a broad application prospect in high-pressure, high-load vacuum circuit breaker and microelectronics fields. Due to the special nature of tungsten copper material itself, it is basically prepared by PM (Powder Metallurgy) process, but also for this reason that makes the structure and properties of tungsten copper alloy products subject to certain restrictions.

In order to make the organizational structure of tungsten copper contact more reasonable, the relevant researchers made many attempts in recent years, such as PIM (Powder Injection Molding), functionally graded materials, nano-structure and W-Cu tungsten fiber reinforced composite structure. Here we focused on the preparation of the fibrous structure of tungsten copper contacts and analyze the factors that affect performance and ablative infiltrated. The use of vacuum infiltration process, and select netting lamination to tungsten as weft, warp knit copper-dimensional net. Under vacuum condition, liquid copper has better liquidity and there is no air in the pores, which is more conducive to liquid copper fill-in. Tungsten braided copper mesh (copper as the infiltration time of induction of copper) and copper billets, and then the two stacked together in a vacuum sintering furnace infiltration, and sintered copper above the melting point (about 1300 ℃).

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Denitration Catalyst Raw Material

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 15:42

Denitration catalyst is the core part of the SCR denitration technology, which determines the entire denitration system efficiency and economy. The current raw materials for producing SCR denitration catalyst in China are titanium dioxide, vanadium pentoxide, tungsten trioxide, stearic acid, ammonium metavanadate, polyethylene oxide, monoethanolamine, carboxymethyl cellulose, lactic acid, wood pulp and glass fiber ect.. Wherein the titanium dioxide as the carrier takes a larger proportion of about 85%; tungsten trioxide and vanadium pentoxide as the principal active ingredient, accounting for about 10%, of which about 7% is vanadium pentoxide. These three components account for about 95% of the total mass of the catalyst, other components although the proportion is relatively small, but they are also important with different physical and chemical properties.

Denitration catalyst is the core part of the SCR denitration technology, which determines the entire denitration system efficiency and economy. The current raw materials for producing SCR denitration catalyst in China are titanium dioxide, vanadium pentoxide, tungsten trioxide, stearic acid, ammonium metavanadate, polyethylene oxide, monoethanolamine, carboxymethyl cellulose, lactic acid, wood pulp and glass fiber ect.. Wherein the titanium dioxide as the carrier takes a larger proportion of about 85%; tungsten trioxide and vanadium pentoxide as the principal active ingredient, accounting for about 10%, of which about 7% is vanadium pentoxide. These three components account for about 95% of the total mass of the catalyst, other components although the proportion is relatively small, but they are also important with different physical and chemical properties.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Desulfurization Catalyst Uses Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 15 April 2016 15:39

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com