Precautions of Electron Gun Filament

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 17:55

As a medical EB tungsten filament, EB tungsten filament is one of the most important parts of medical treatment. The notices of the EB tungsten filament become more important.

The medical EB tungsten filament can be divided into two types: non detachable and detachable. With the increasing time to use medical EB tungsten filament, the filament will gradually aging and the measuring rate of the machine will gradually decrease or not be able to produce light. At this time, the maintenance engineer should first check on the current number, if the number is not zero, people can appropriately adjust the EB tungsten filament current, and it can be maintained at a relatively stable state to work.

While exchanging the medical EB tungsten filament, there are the some points to notice: first of all, people should ensure that there is sufficient dry nitrogen in accelerating tube system before the exchange, so as to avoid harmful gases penetrate into the system. After removing the EB tungsten filament, the accelerating tube port should be covered by protective cover as soon as possible, put the EB tungsten filament in a clean platform.

There are several more details of precautions:

1. People should check whether the voltage nitrogen less than 14 bar or not while filling nitrogen, if the value is less than 14 bar, you need to change another cylinder. 2. Pay attention to keep a dry and clean environment when exchanging the EB tungsten filament. 3. Engineer should wear a mask, hat and gloves, to prevent the EB tungsten filament from dust and oil pollution.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Brief Introduction of IG Tungsten Filament and Ion Source

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 17:24

The full name of IG tungsten filament is ion gun tungsten filament, it can also be named as ion source tungsten filament.

An ion source is a device that creates atomic and molecular ions. IG tungsten filament is used to form ions for mass spectrometers, optical emission spectrometers, particle accelerators, ion implanters and ion engines. The types of ion source can be divided into 7 categories which include RF ion source (radio frequency ion source), Arc Discharge ion source, PIG ion source, Double Plasma ion source, Double Peng source, Ionic Charge Transfer source, and Ionic Sputtering source.

The IG tungsten filament is made of tungsten wire, features high melting point and high corrosion resistance, mainly applied for vacuum metalizing, such as aluminizing scope, chrome scope, mirrors, plastics and heaters elements for decoration articles. The current source of IG tungsten filament is supplied by the three-phase 380V AC.

The IG tungsten filament is thermostability. It has a great flexibility and a long life. The application areas of IG tungsten filament include electrical optical film and film art, plastics, ceramics, glass crystals, coating a substrate, such as: the infrared film, broadband antireflection coatings, transparent conductive film interference filter cut-off polarizing film, a metal compound film, VCD beam splitter, various types of laser film.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

EB Tungsten Filament and Cathode

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 17:21

Generally speaking, The EB(electron beam) tungsten filament consists of a cathode focusing electrode, and an anode. As a term of the electrochemical reaction, the cathode of EB tungsten filament refers to obtain electrons pole which can produce the reduction reactions. The cathode is an important part of the EB tungsten filament, which determines the ability of emitting and the life length of electron beam.

Nowadays, the most widely recognized of the form of the cathode is the directly heated cathode indirectly heated cathode, the latter can be divided into bombardment type and heating type. Bombardment-type offers hundreds or even thousands VA(volt-ampere) to the EB tungsten filament, when the cathode is heated to a certain temperature and then it will produce a large number of electrons. For heating type, when EB tungsten filament burned the cathode by electric current flowing. If the cathode reaches the temperature, then it can produce the electrons.

The temperature of EB tungsten filament has a strong influence on the intensity of the electron emission. Under the same emission intensity conditions, if the recovery percent of cathode material is small, then the temperature of the EB tungsten filament can be greatly reduce. It benefits to protect the EB tungsten filament. If users want to lengthen the life of the EB tungsten filament, people should choose cathode materials with a higher melting point and a smaller evaporation rate.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

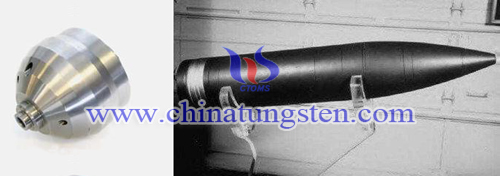

Tungsten Alloy Shielding for Neutron Bomb

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 16:47

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

What is Tungsten Gold Plated Bar?

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 16:45

| Tungsten Gold Plated Supplier: Chinatungsten Online tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Gold Pendant

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 16:43

| Tungsten Jewellery Supplier: Chinatungsten tungsten-jewellery.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Microwave Sintering (2/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 16:16

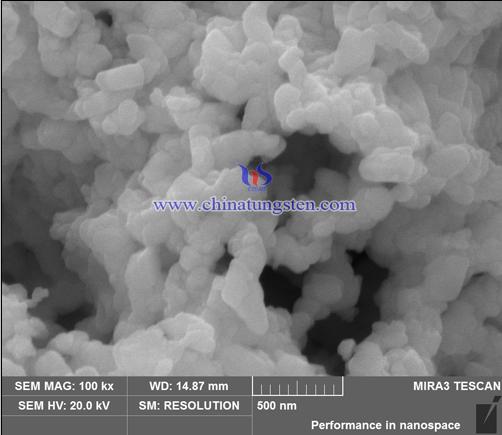

From microwave sintering temperature and holding time point of view, the sintering temperature rises to a certain temperature, density tungsten copper contact materials increases, the relative density of up to 99.8%, close to fully densification. This is due to the temperature rise reduces the wetting angle, improved copper solution on a solid phase wettability of tungsten, reducing the resistance of the particle rearrangement process, the particles rearrangement sufficiently improve the densification rate. Meanwhile, temperature increases can also reduce the viscosity of liquid copper and increase in liquid copper capillary force mobility, which will be conducive to densification. But thereafter the temperature increased, lower relative density decreased, which is due to the reduced coefficient of viscosity, the effect of gravity copper deposited on the bottom of the fluid will gradually lead to the formation of a new gas into the pores, thereby reducing the density.

The sintering additive also has a great impact on the tungsten copper contacts sintering densification. The experiments show that adding a small amount of Co, Ni can significantly improve the solubility of W, and help to improve the ability of densification. In the liquid phase sintering process, W in solid solution reacted with sintering aid or intermediate phase. And the product will form a continuous layer of wrapping on W grains surface, which can significantly reduce the surface tension between the liquid and the copper particles W and improve wettability of the two phases.

In addition, copper liquid under the action of capillary force, the gap between the W particle flow and cause a rearrangement of W particles, thereby significantly promoting compact shrink compact. However, copper liquid flow too often will lead to the emergence of copper accumulation pool, even reduce the uniformity of the sample. Overall, by analyzing the experimental data, in the manufacture of tungsten copper alloy contact process, the microwave sintering technology compared to conventional sintering has a significant advantage in heating rate and sintering cycle; sintering additive selection can promote the densification of tungsten copper contacts;samples of microwave sintering has more uniform microstructure and better mechanical properties.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Copper Contact Microwave Sintering (1/2)

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 16:14

Except conventional sintering process, microwave sintering as a new sintering process is also gradually began to apply in the tungsten copper material. It uses special microwave band has the fine structure coupled with a basic material to generate heat, and material dielectric loss in the electromagnetic field of the material as a whole it is heated to the sintering temperature to achieve densification. Microwave sintering has many advantages, such as volumetric heating, heat conduction from the inside out and stepwise temperature distribution within the high outside low, which are beneficial for heating rate, sintering time and energy efficiency. For powder metallurgy industry, it is essential that lower cost of production and lower energy consumption, so microwave sintering has a broad prospect in tungsten copper contact.

Tungsten copper (W-Cu) contact is a kind of psudoalloy that consist of W and Cu immiscible and with a great difference in the melting point, which means it is difficult to achieve higher density by conventional sintering method and it has a bad influence on the electrical and thermal conductivity, hermeticity and other mechanical properties. Compared with conventional sintering process, microwave sintering can effectively improve the density of tungsten copper contact materials to improve the microstructure and increase other comprehensive performance.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Bronze Properties and Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 April 2016 15:44

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Electrochemical Method of Tungsten Bronze Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 11 April 2016 18:40

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com