High Pressure Tungsten Powder Preparation by The Mixture of Ammonium Paramungstate and Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 23 February 2018 16:26

At present, in order to prepare tungsten products with high density and high temperature, the pressing and forming properties of tungsten powder are required. Therefore, it is very important to optimize the compacting and forming properties of tungsten powder.

Preparation of Tungsten Hexafluoride from Waste Tungsten Cutting Head

- Details

- Category: Tungsten Information

- Published on Friday, 23 February 2018 15:25

In tungsten fluoride, tungsten hexafluoride (WF6) is the only stable and industrialized production of varieties. It is an important raw material in modern electronics industry. It can be used to produce high-purity tungsten powder as raw material for metal tungsten chemical vapor deposition (CVD) process, especially the WSi2 made from it can be used as wiring material for large-scale integrated circuit (LSI).

Sintering - Plastic Flow

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:39

Sintering - Boundary Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:35

Sintering - Surface Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:32

Sintering - Volume Diffusion

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 22:28

Why Spherical Tungsten Powder is The First Choice for Thermal Spraying Materials

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 21:46

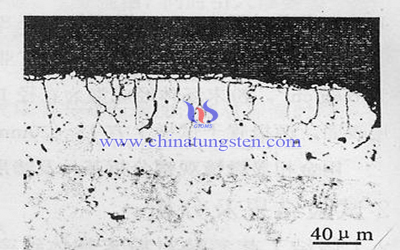

Tungsten is an important thermal spraying material. Thermal spraying technology uses heat source to heat the spray material to melt or semi dissolve state, and spray at certain speed to deposit the coating on the pretreated substrate surface. The thermal spraying technology makes a special working surface on the surface of the ordinary material.

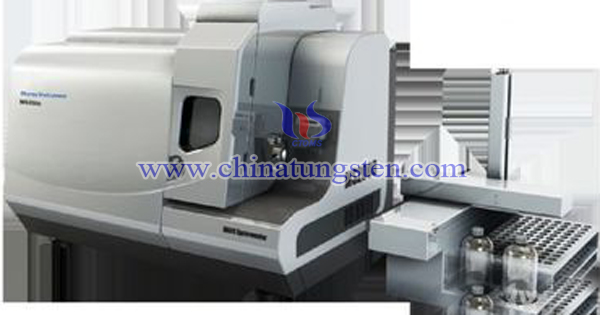

Determination of Tungsten Carbide with Inductively Coupled Plasma

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 21:22

Hard alloy with high hardness hard tungsten carbide micron metal powder as the main ingredient, with cobalt (Co), nickel (Ni), molybdenum (Mo) as the binder, powder metallurgy products in vacuum furnace or hydrogen reduction furnace in sintering, different tungsten content plays a key role in the performance of the alloy. The detection requirements must be accurate and reliable, the test for the tungsten content of hard alloy mainly has the gravimetric method, colorimetry and atomic absorption spectrometry.

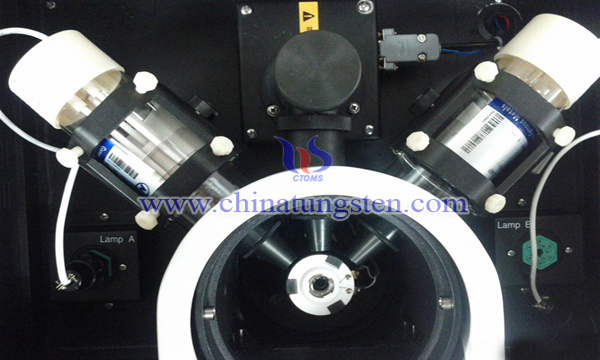

Determination of impurities in Tungstate by Atomic Fluorescence Spectrometry

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 15:41

Tungstic acid is acidic substances a yellow powder, tungsten trioxide containing about 90%, also contains trace tin, molybdenum, silicon, calcium, iron, manganese, potassium, sodium, chlorine, phosphorus, sulfur, arsenic, antimony, magnesium and other elements, is the raw material for the production of ammonium paratungstate.

How to Effectively Remove Sodium and Chlorine from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 22 February 2018 14:40

With the development of the subsequent product process of tungsten, tungsten wire, tungsten powder, tungsten bars and other high-end hard alloy material of ammonium paratungstate rising, ammonium paratungstate zero grade existing national standard has been unable to meet the requirements of high-end hard alloy, not only the impurity and physical of ammonium paratungstate can put forward certain requirements, and part of the production of high-end products enterprises to individual impurity elements proposed particularly stringent requirements.

sales@chinatungsten.com

sales@chinatungsten.com