Maximum Injection Volume and Injection Pressure

- Details

- Category: Tungsten Information

- Published on Sunday, 24 September 2017 22:01

Injection volume, injection pressure, injection rate, plasticizing ability and clamping force are main parameters of injection molding machine. They are the basis for designing and using an injection molding machine, and are also important parameters in the injection molding process.

A, Maximum Injection Volume

The maximum injection volume of an injection machine when the screw completes a maximum injection stroke (axial movement).

Representation Method:

1, polystyrene with a density of 1.05g/cm3, expressed in weight, in units of g.

2, the amount of injection expressed as the volume of the melt to be injected, unit cm3. This method is more commonly used due to it is easy to use and has nothing to do with the density of the material.

At present our country injection machine standard specification has 18 kinds (cm3), ranging from 30 to 64000.

B, Injection Pressure

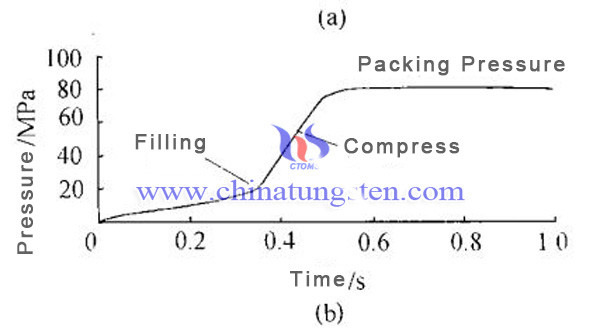

In the injection molding process, there are three basic pressures: plasticizing pressure, injection pressure and packing pressure (as shown below). Injection pressure is the unit area pressure of the screw acting on the head melt in the injection process, and its unit is Pa. The injection pressure is closely related to the material type, injection machine type, mold structure, plasticizing temperature, product wall thickness and other process conditions, especially the structure and size of the injection device.

When the injection pressure is too high, the flying edge, difficult demoulding and low surface finish may occur. Even serious, the product may be scrapped.When the injection pressure is too low, it is easy to cause the product is not full, and even the problem of forming.

When the injection pressure is too high, the flying edge, difficult demoulding and low surface finish may occur. Even serious, the product may be scrapped. When the injection pressure is too low, it is easy to cause the product is not full, and even the problem of forming.

Selection of Injection Pressure:

1, If the product has relatively simple shape, large wall thickness and good material flow, injection pressure may be less than 70MPa.

2, Injection pressure (70-100MPa) is generally used for low precision products.

3, injection pressure in 100-140MPa is used in medium, high viscosity materials, and shape, precision requirements of the general products.

4, Injection pressure (140-180MP) is usually used to prepare products with thin wall, long process and high precision.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com