Plunger Type and Reciprocating Screw Type Injection Machine

- Details

- Category: Tungsten Information

- Published on Sunday, 24 September 2017 21:56

According to the plasticizing form of materials, injection molding machine is divided into two types: plunger type injection machine and reciprocating screw type injection machine. The screw type injection machine is in the majority. Because of their different structures, their characteristics are not the same.

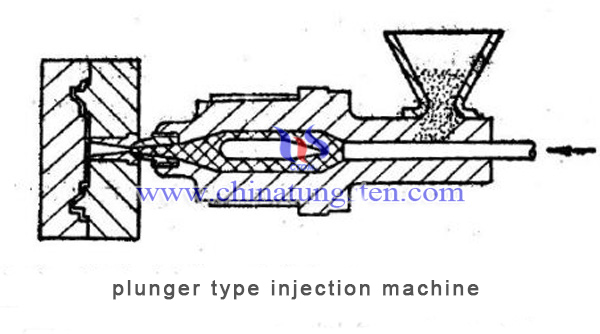

One, Plunger Type Injection Machine

The plunger injection system mainly consists of feeding device, barrel, plunger, split shuttle, nozzle and mould etc. (shown in Figure 1). In addition to the plunger and screw, the plunger type injection machine is different from the split distributor of the screw type injection machine. Split shuttle is a torpedo shaped part arranged in the inner cavity of the front of the material cylinder, which plays a role in diverting material, increasing heat transfer area and reducing the thickness of the material layer.

Disadvantages of The Plunger Injection System:

1, Uneven plasticizing. materials are mainly plasticized by heat transfer through the heater. Without shear heat generation by screw injection, the temperature difference in the barrel is large.

2, Greater injection pressure loss. Its pressure loss mainly includes the resistance to the cavity, the extrusion of materials, the movement of materials and the resistance encountered through the shuttle. Large pressure loss is easy to cause difficulty in mold filling.

3, Uneven injection speed. In the operation, we must first compaction material (screw also has this process, but can be seen as a uniform process). After compaction, the injection speed of the plunger is consistent with the injection rate of the melt.

As a result, generally only small injection machine to use the plunger program.

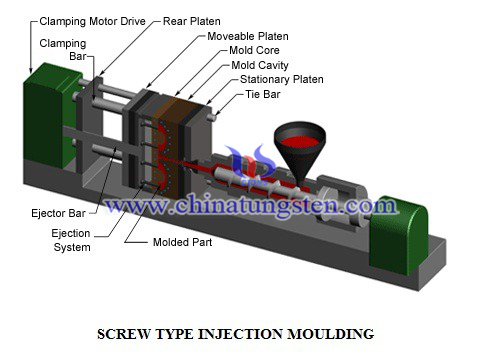

Two, Screw Type Injection System

Screw type injection system mainly include injection cylinder, hydraulic motor, feeding device, cylinder and screw, nozzle and mould etc.

Advantages of Screw Type Injection System:

1, The screw rod acts as the plasticizing material (extrusion and shearing), and has the extruding action of injection material. When the screw rotates and retreats, the material is plasticized and transported to the end of the screw due to the extrusion and shearing of the screw. But when the screw moves forward, it acts as a plunger on the material.

2, Compact structure, high plasticizing efficiency, uniform plasticizing, low injection pressure loss.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com