Preparation of Tungsten Coating Strengthened Molybdenum Crucible

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 February 2018 21:39

In the industry, the melting of rare earth, vacuum evaporation and sapphire growth in the field of crucibles, mostly made of tungsten and molybdenum materials. This is due to the fact that tungsten has the characteristics of high melting point and high density. Currently, tungsten, molybdenum and molybdenum alloy crucibles are mostly obtained by powder metallurgy and press working.

Optimization of Ammonium Tungstate Solution by Ion Exchange Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 February 2018 20:04

Ion exchange method is currently China's tungsten smelting main purification process. At present, strong alkali anion resin 201 x 7 and weak alkaline anion resin are mainly used in the ion exchange process of removing impurity and transforming the tungsten solution.

Extract Alkali from Crude Sodium Tungstate Solution

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 22:29

Scheelite is hard mining and smelting tungsten smelting raw material in the last century, when alkali pressure leaching and scouring process of popularity, production capacity and size of scheelite smelting technology has been greatly enhance, and also further mature. Due to the excessive alkali process, although the leaching process consumes a large part of the base, but after the reaction, residual alkali from crude sodium tungstate solution is very high.

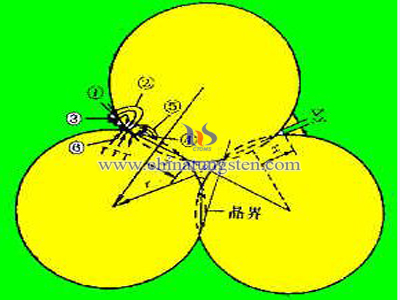

Sintering Mechanisms of Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 19:04

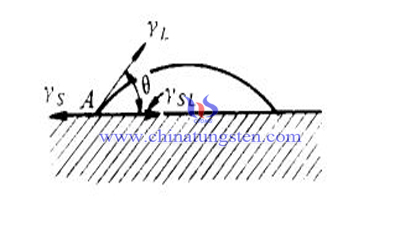

Wettability of Sintered Liquid Phase

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 18:58

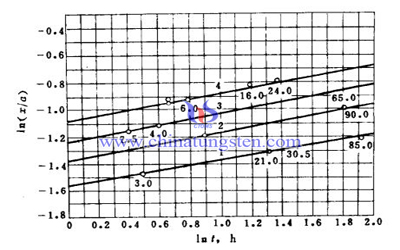

Determination of Sintering Mechanism

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 18:54

Comparison of Various Sintering Mechanisms

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 18:50

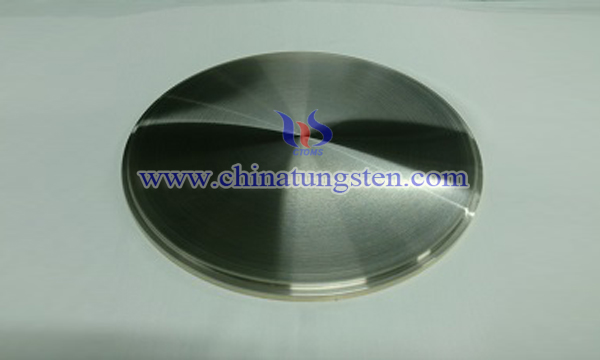

The Manufacturing Process of Tungsten Titanium Alloy Target

- Details

- Category: Tungsten Information

- Published on Monday, 19 February 2018 15:20

Tungsten titanium alloy target with low resistance coefficient, good thermal stability and oxidation resistance properties, diffusion barrier layer has been successfully applied to Al, Cu and Ag wiring, and has been widely studied and applied in semiconductor and solar energy industries in terms of sputtering.

A Brief Introduction to The Preparation of Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 19 February 2018 15:03

In recent years, with the continuous development of science and technology, spherical tungsten powder is widely used in thermal spraying, porous materials and powder metallurgy industry, and its demand is also increasing. In the field of thermal spraying, the spherical tungsten powder is not only well fluidity, but also the coating is more uniform and compact, so the product has better wear resistance.

The Strategy of Recycle and Utilization of Tungsten Tailings for Plastic Packing

- Details

- Category: Tungsten Information

- Published on Monday, 19 February 2018 14:24

Tungsten tailings are the solid wastes produced after the classification of tungsten ore. At present, the comprehensive utilization mainly includes the recycle of useful metals and non-metallic ores, but the amount of metal recycle components is small and a large amount of tailings remains. It is used in the production of glass ceramics, ceramics, fire free bricks and hollow bricks, with limited use, high process cost and limited application benefit.

sales@chinatungsten.com

sales@chinatungsten.com