Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅵ

- Details

- Category: Tungsten Information

- Published on Monday, 14 September 2015 17:10

3. Results and discussion

3.1. Coating characterization

Fig. 2 shows the thickness of the Co interlayer as a function of sputter time at fixed Co sputter current of 0.4 A. The thickness of Co interlayer linearly increased from 0.027 μm to 0.160 μm with increasing the sputter time from 10 to 60 min. This result reflects that our hybrid coating system enables an easy control of Co interlayer in synthesis of TiN/Co/WC-Co systems. After deposition of Co interlayer, the TiN coatings were deposited under condition shown in Table 1 by AIP method. The thickness of TiN was approximately 2.5μm. Additionally ,the micro-indentation hardness of the TiN coating layers were found to almost constantly maintain from 27 GPa to 30 GPa at approximately 0.027 μm of thickness of Co interlayer. However, the hardness of TiN having Co interlayer linearly decreased with further increase in the thickness of Co interlayer. This effect is related to a change in the mean free path of Co, which is defined as the thickness of Co in the WC-Co system.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Dos and Don’ts of Tungsten Darts Etiquette

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 19:36

Violations of tungsten darts etiquette result in less fun being had and fewer games being played. If you do any of these things, please stop! If your friends do these things, slap them and tell them what’s up. Friends don’t let friends ruin darts for others. Those who know are responsible for the future habits of those who don’t.

DO be a good sport. People playing tungsten darts are looking to have fun.

DON’T talk to someone throwing unless they are your teammate, and they are okay with being talked to while at the line. If you don’t know, ask them before their next throw.

DON’T talk loudly next to or behind someone throwing. Some doing this are oblivious, while others do it intentionally to get an edge. All tungsten darts players should discourage this even if they are not involved in the match.

DO move smoothly and deliberately without hesitation while retrieving tungsten darts. If you have a bounce-out into a neighboring lane, you can either waiting at the line for them to finish or get low and reach for it like a ninja.

DON’T ever turn and watch someone throw while you are walking back from pulling your tungsten darts. Walk straight and silently until you completely pass their field of vision before turning around to watch.

DON’T stand in the thrower’s field of view. If you can’t avoid it, don’t make sudden moves. In those cases, print a map (from linked article) and give it to your bartender.

DO stand still while chalking steel tip matches. Sudden movements may result in tungsten darts thrown at you. If the player throwing is on an opposing team, it is unsportsmanlike.

DON’T distract games in progress. If you are practicing on a board adjacent to players in a league or tournament match, be considerate and change to a further board when practical.

DO learn the fist-bumping culture of where you are playing and participate. Some bump every player on every throw, some only bump their teammate, some only bump great turns, some only bump before and after matches, and some never bump. Going against the culture of the bar and its players is impolite. Fist bumps encourage camaraderie and remind everyone that they are playing a game for fun, even when money is on the line.

DON’T practice on other boards if involved in a league or tournament match. Muscle memory is a huge factor and extra throws are typically considered an unfair advantage. One generally acceptable exception is when a participating player goes to the bathroom and everyone is left waiting.

DO play at a reasonably quick pace. Use the bathroom before and after matches. Stay near the tungsten darts area, pay attention to the game, and minimize the time that others are waiting on you.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

American Darts History

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 19:33

There are many theories about how darts found its way across the Atlantic; the most popular being that the Pilgrim Fathers took the game with them – and indeed played it - on the Mayflower when they sailing into self-imposed, permanent exile in the ‘New World’ back in 1620.

One darts writer, Keith Turner, challenged the ‘facts’ back in 1980 in his book Darts - The Complete Book of the Game and stated that he could find no evidence to support the theory. Keith added, “In view of their beliefs and code of living it is extremely unlikely that they played any other sort of games either.” Their credo would simply not have allowed it.

Determined came as no surprise to me that the Curator of Exhibits replied that he could find no evidence whatsoever to support such a theory stating “We have researched this in depth and have to confess that we have found no mention or hint of this in our records.” More recently, to close the book on this, Dan William Peek (2001) undertook research with The Pilgrim Society and knocked the ‘fact’ back into the realms of fiction.

It was Dan who set out on an epic journey to seek out the true history of the sport of darts in America. His book To the Point: The Story of Darts in America is an essential work and should be read by anyone interested in darts ‘across the pond.’ It is not my intention here to lift sections of Dan’s work into this article.

When the Americans joined the Second World War, they ‘invaded’ Britain and thousands were stationed in towns and villages up and down the country. One of the activities that appealed to the ‘Yanks’ whilst they were ‘over here’ was visiting the local pub and what did they find in the pub? Yes, darts. A great number of those servicemen and women took darts back home with them and helped spread the word of darts in the post-war years across North America.

American Darts Organization With the coming of the British Darts Organization and the World Darts Federation in the 1970s, darts went well and truly international. In the USA the lead was taken by the late, much-lamented Tom Fleetwood who founded the American Darts Organization (ADO) and with his wife Della and many other colleagues worked great things for US darts for many years.

In addition to Dan William Peek, who has researched the broad history of the sport of darts in the USA, there are a few enthusiasts out there that have recorded the history of their own darts organizations. One of these is Ed Otjen who, in 1999, wrote an 18-page history of the Twin City Darts Association especially to celebrate the TCDA’s 25th Anniversary and was presented at the special Anniversary Dinner in the fall of that year.

Nowadays, tungsten darts have popularized between darts fans. Because tungsten darts are made of high-density metal, so they’re smaller than other materials darts (in the same weight), in the mean time, tungsten darts is environment-friendly.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Characteristics and Classification of China’s Tungsten Deposits

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 18:33

The first tungsten deposit in China was discovered in 1908, and since the end of 1920s, the annual output of tungsten in China has averagely made up 40 percent of the total annual tungsten output of the world.

The basic geological characteristics of China’s tungsten deposits might be summarized as wide in distribution ,numerous in production place, large in size ,rich in grade, complex in associated components and varied in ore deposit types. In addition, China’s tungsten resources are famous in the world for its highly developed quartz vein type tungsten deposits.

The classification of tungsten deposits depends mainly on the research level of their geneses. Polynary metallogenic should serve as the major basis for this classification, and whether the ore-prospecting prognostic information can be provided or not is also a principle for classification.

China’s tungsten deposits can be classified into rock-controlled tungsten deposits and stratabound ones. The former is further divided into two subclasses, i.e., crust-derived tungsten deposits and tungsten deposits from mixed crust-mantle sources, and the latter also into two subclasses , namely, reworked tungsten deposits and superimposed ones, with the addition of modern supergene tungsten deposits. Finally, these deposits are divided into a number of types according to ore-forming process. A simplified classification is given in the paper.

Tungsten deposits are distributed all over 29 provinces, municipalities and autonomous regions of China. With 30° north latitude as the boundary, this paper divides China into North China and South China and differentiates sixteen metallogenic belts which are described in detail.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Experimental Research on Ferro-Molybdenum-Tungsten Ore Processing

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 18:29

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Glass Coating Method

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 18:15

Sol-gel is a good technique, but if you want low costs and want to minimize mess, go for spin coating.

Create a

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Oxide Coatings from the Aerosol-Assisted Chemical Vapor Deposition of W(OAr)6

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 18:11

Tungsten hexaaryloxide complexes of formula W(OAr)6 (Ar = C6H5, 1; C6H4F-4, 2; C6H3F2-3,4, 3) have been synthesized by the reaction of W(O)Cl4 and ArOH in 22−28% yield. The complexes were characterized by 1H, 13C, 19F, and 183W NMR (1, δ = −474.8; 2, δ = −416.3; 3, δ = −446.3), melting point (1, 95 °C; 2, 101 °C; 3, 105 °C), IR, microanalysis, and single-crystal X-ray diffraction (octahedral coordination). Aerosol-assisted chemical vapor deposition of W(OAr)6 using acetone and toluene solvents and substrate temperatures from 300 to 500 °C produced blue tungsten oxide films on glass substrates. The films were analyzed by glancing angle powder diffraction and shown to be amorphous at 300 °C, but consisted of crystalline WO3-x at higher deposition temperature. Annealing the films from 1 at 550 °C in air for 30 min produced yellow γ-WO3 with preferred growth in the [020] direction.

Raman analysis of the as-formed films showed WO3-x with evidence for WV−WVI paired ions. Annealed samples produced Raman patterns for γ-WO3 (807, 715, 273, and 133 cm-1). The films were adhesive to the substrate, conformal, passed the Scotch tape test, and gave good coverage. Typical growth rates were 20−50 nm min-1. SEM showed uniform films consistent with an island growth mechanism. Energy dispersive analysis confirmed the presence of only tungsten and oxygen. XPS showed that the as-formed films were WO3-x (x ≈ 0.22) with binding energy shifts for W 4f5/2 at 37.2 and 4f7/2 34.4 eV and for oxygen 1s at 532.6 eV. The as-formed films had an absorption maxima at 320−360 nm (dependent on film thickness) and an onset for absorption at 400 nm. Reflectance/transmission measurements produced interference fringes that enabled a calculation of film thickness. In general the films showed good transmission from 500 to 1000 nm (60%) and some reflectivity (ca. 20%) over the same region. After annealing, the absorption edge was pushed more into the visible and the films showed evidence for some scattering associated with haze. The blue WO3-x films showed negligible photocatalytic activity. The annealed, yellow WO3 films were active photocatalysts and readily destroyed an overlayer of stearic acid.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball National Standard (JBT9145-1999) II

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:59

Continued:

11. Less burning: The sintering temperature of the products is too low or the sintering time is too short to make the product does not meet the required sintering properties.

12. Stratification: Products compacts or the layered defect in sintered body and the defect itself.

13. Cracks: The irregular interface and shades of cracks in the surface, corner and bottom of products.

14. Impurity: The small pores or inclusions observed in the section of the products by LP (low-powered) microscope.

15. Porosity: The ratio of total pore volume and the products volume.

16. Non-combined carbon: The free graphite in the structure of tungsten carbide.

17. Dirt degree: The length is no less than 50 μm and has clear edge, pore observed by 100-100 times metallurgical microscope is called as dirt, which the total length of all the dirt on grinding every square centimeter of (cm2) is called dirt degree.

18. Some visible pits with bright bottom on the surface of tungsten carbide ball.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball National Standard (JBT9145-1999)

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:56

Tungsten carbide ball national standard illustrates the size and technical conditions of every tolerance levels tungsten carbide ball, which is widely used in instrument probe, special bearings and some other tungsten carbide ball manufacturing and tests. There are some defined terms, symbols and explained as follows:

1. Nominal diameter of the ball Dw

2. Single diameter of the ball Dws

3. The average diameter of the ball Dwm

4. The diameter variation of ball VDws

5. Spherical error△Spu

6. Batch L(Lot)

7. The average diameter of the batch DWml

8. The diameter variation of the batch VDwl

9. Tolerance level of the ball

10. The deviation of the batch average diameter: The D-value between the average diameter of the batch and nominal diameter.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅴ

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:39

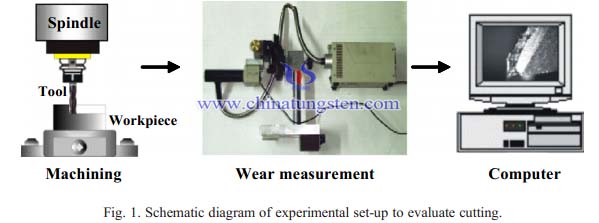

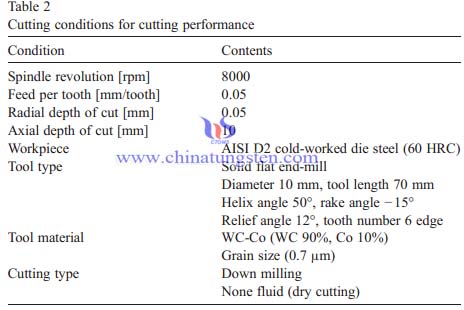

2.3 Cutting test

Fig. 1 shows the schematic diagram of the experimental set-up to evaluate cutting performance . The experiments were carried out without any coolant in a vertical machining center (MAKINO, V-55). Tool wear was measured by a CCD camera (PULNIX , X200 ), which was attached on the machine table. The cutting test was started with a fresh cutting tool, and the machining process was stopped at certain intervals of cutting length in order to measure the width of flank wear. Flank wear was obtained by the average value measured on three points of cutting edge within the axial cutting depth. The flank wear of 0.3 mm was used as a tool life criterion for a comparative evaluation of the TiN coating on the WC-Co substrate and the three types of the TiN coating tools with Co interlayer. The workpiece used in the experiment s was die steel (AIS I D2, 60 HRC). The experiments were carried out under cutting condition shown in Table 2 . The tool manufacture used at experimentation was made by Sung-Jin Tech Co. (Korea) as solid flat end-mill. To verify the goodness of fit for tool wear distribution, the best coated cutting tool was tested 18 times repeatedly. The probabilistic function of tool wear was analyzed by normal, log-norma l and Weibull distribution. The χ2 (chi- square d) test was also used to verify the goodness of fit. This test allows us to compare a collection of categorical data with some theoretical expected distributions

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com