Tungsten Carbide Ball Bearing VIII

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 17:15

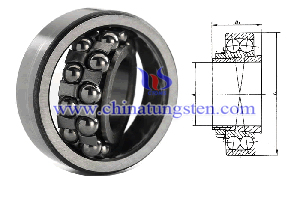

The maximum capacity or filling slot type radial ball bearings have inner and outer races that are notched so that when they are aligned, additional balls can be slipped into the slot in order to fill the bearing. The advantage of this bearing is that the entire groove is filled with balls. This is called a full complement/capacity which allows these bearing types to carry increased load ratings.

Although designed to carry primarily radial loads, which are loads perpendicular to the axis of the bearing, the deeper the contour of the rolling track, the greater the ability of the bearing to tolerate thrust loads placed along the axis of the bearing. These bearings are designed for use in high speed, high precision applications for the agriculture, automotive and chemical industries. They are also found in engines, motors, hand tools, fans, etc.

For tariff purposes, radial ball bearings are divided into three types: single row ball bearings, double row ball bearings (bearings having two rolls of balls that revolve around the ball path) and bearings having more than a double row of balls. The single row ball bearings are further broken down into the maximum or full capacity type or the non-filling (Conrad) type. The ten digit classification for the Conrad type bearings is dependent on the outside diameter of the bearing. For tariff purposes, flanges and other projections from the outside surface of the outer race or ring are not included in the measurement of the outside diameter.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

http://news.chinatungsten.com/en/tungsten-information/78843-ti-10039

http://news.chinatungsten.com/en/tungsten-information/78844-ti-10040

http://news.chinatungsten.com/en/tungsten-information/78892-ti-10051

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing VII

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 17:11

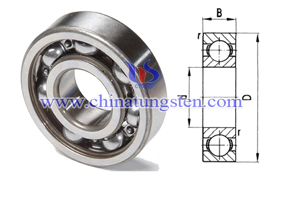

Radial Ball Bearings:

Radial ball bearings are the most common and most widely used ball bearing due to their versatility and durability. There are two basic types of radial ball bearings: the non- filling or Conrad type and the filling slot or maximum capacity type. The inventor of the Conrad type bearing assembly procedure, Robert Conrad, was given British patent no. 12,206 in 1903 and U.S. patent no. 822,723 in 1906.

This method of construction places an inner ring inside of the outer ring. With the rings aligned in the same direction, the inner ring is positioned so that it touches the outer ring at one point. This creates a crescent-shaped open area where an appropriate number of balls are placed. The inner ring is then snapped back to its original position in relationship to the outer ring. The balls are evenly distributed around the raceway, and the retainer is assembled into place. Most radial ball bearings are assembled using the Conrad method of construction.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

http://news.chinatungsten.com/en/tungsten-information/78843-ti-10039

http://news.chinatungsten.com/en/tungsten-information/78844-ti-10040

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten A Strategic Metal

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 16:54

In 1913,the British mining interests had no use for tungsten considered it a nuisance because it made tin extraction more difficult. But as World War І began, military and economic experts assured each other and the world that Germany could not keep up its industrial pace,and that its ammunition supply would be exhausted in six months.But it was soon discovered that Germany was increasing its munitions output,even exceeding that of the Allies.Germany's top-secret then was the use of tungsten high-speed steel in cutting tools.And the ore,the British found out later,had been coming from their own Cornwall mines.

With this impetus,due to demands of military might,world production of tungsten had leaped by 1916 to 23,104 short tons of concentrates. Only nine years before it had been6135 short tons-an amount in those days considered surplus.

Tungsten was establish as a strategic military item in the munitions race of World War І,but the military requirements for this metal became astronomical during World War Ⅱ with the introduction by the Germanys of a tungsten carbide armor-piercing shell.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Basic Applications of Tungsten Carbide BurrsⅡ

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 15:33

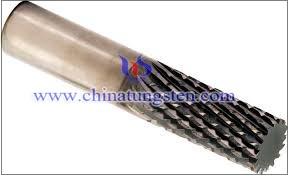

In last part we revealed that Tungsten carbide, in different shapes such as round, cylindrical and oval, and with different cuts, single or double, are used for rapid removal of excess materials, or of burrs from jagged, sharp edges, and also used prior to polishing or finishing with coated abrasives when usually the work pieces can be steel, cast iron, aluminum, etc., of which a die grinder is an example.Here we talk about the carbide burrs’ application in cylinder head porting and sculpturing.

Porting is another method in which application of the carbide burr is necessary. Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the gas flow. Porting the heads provides the finely detailed attention required to bring the engine to the highest level of efficiency. Theoretically, polishing with abrasives affects the fuel flow and ultimately the porting process is responsible for the high power output of modern engines (Cylinder Head Porting June 2008).

Lastly, another common application and use of the tungsten carbide burr is utilized by sculpture. They provide vibration-free cutting and grinding. The shank is made of high tensile stainless steel. Diamond burrs are created by bonding diamond particles by means of electroplating with uniform size and exceptionally sharp-edged for fast cutting. Carbide burrs are precision fluted and can cut just about any material such as bronze, brass, aluminum, steels, wood, and all types of stone.

(----The end. This article is divided into 2 parts and here is part 2. For part 1 please refer to:http://news.chinatungsten.com/en/tungsten-information/78877-ti-10048 )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Basic Applications of Tungsten Carbide BurrsⅠ

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 15:28

Tungsten carbide burrs are used for rapid removal of excess materials. Ironically, burrs are both referred to as the excess shavings of material and the actual carbide burr tools used to remove rough edges after the machining process. The removal of burrs from jagged, sharp edges is another common application for carbide burrs. In addition, carbide burrs are a supplemental type of tool that is used prior to polishing or finishing with coated abrasives. Tungsten carbide burrs can be used on cast iron, steel and aluminum. Depending on the type of surfaces that are accessible, carbide burrs can be utilized because of the different shapes in which they are manufactured. Typically, carbide burrs are made in inch diameter shapes such as round, cylindrical and oval. Carbide burrs are created with different cuts. Single or double cuts are used for steel and cast iron surfaces. According to Monroe (1997, p. 28), a course single cut minimizes the tendency of the cutter to load up with aluminum.

A die grinder is a handheld tool which turns a burr at a high rate of speed. It is usually pneumatic (powered by compressed air), although electric die grinders are also common. The burr is held in a bit holding device and may be changed as required. The rotational speed of a pneumatic die grinder is adjusted by a hand-operated throttle which allows the operator to fluctuate the volume of compressed air entering the tool. Die grinders are used to drudge away small amounts of metal from piece of work. The name comes from their use in touching up hardened steel dies.

Most die grinder throttles feature a spring-loaded “kickstand” mechanism between the throttle lever and the body of the grinder, which prevents the throttle from opening (being pressed down towards the body of the grinder) without operator intervention. This prevents the die grinder from accidentally activating.

(----to be continued. This article is divided into 2 parts and here is part 1.For part 2 please refer to: http://news.chinatungsten.com/en/tungsten-information/78879-ti-10049)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Chemical Composition of Tungsten Carbide Burrs

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 18:20

Tungsten carbide burrs cutters are made from tungsten carbide which allows them to move at high speeds and yet still sustain their cutting edges. Carbide cutting surfaces are often useful when machining through materials such as carbon and stainless steel as well as in situations where other tools would wear away, such as high-quantity production runs. Usually, carbide will leave a better finish on the tool, and permit quicker machining. Carbide tools can also endure higher temperatures than standard high speed tools. The material is usually tungsten-carbide cobalt, also called “cemented carbide”, a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix.

The process of combining tungsten carbide with cobalt is referred to as sintering or Hot Isostatic Pressing (HIP). During this process cobalt eventually will be entering the liquid stage and WC grains (with higher melting point) remain in the solid stage. Machining with carbide can be difficult, as carbide is more brittle than other tool materials, making it susceptible to chipping and breaking. To offset this, many manufacturers sell carbide inserts and matching insert holders. With this setup, the small tungsten carbide insert is held in place by a larger tool made of a less brittle material (usually steel). This gives the benefit of using carbide without the high cost of making the entire tool out of carbide. Most modern face mills use carbide inserts, as well as some lathe tools and end mills.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Introduction to Tungsten Carbide Burrs

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 17:58

Tungsten carbide Burrs, are burrs made of tungsten carbide, also known as rotary files which consist of small and large shaped cutters used in die grinders, rotary tools, and dentist drills. The name may be considered suitable when their mini-size head (3 mm diameter shaft) is closely similar to that of a seed in the burr fruit. Tungsten carbide burrs are also used in CNC machining robot type centers for removing burrs (the small flakes of metal) after a machining process (burrs-cutting). To sustain the right external speed and cutting environment they are rotated at the maximum velocity achievable, appropriate with their size and structure.

In engineering, a burr can be described as the raised circumference on metal. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion on a surface, after being struck a blow from an equally hard or heavy object. Specifically, burrs are as a rule useless residual that is the effect after machine grinding, drilling, milling, or turning. In the following report the word, burr, refers to the excess substance of material and carbide burr refers to the tool that removes the excess material.

De-burring:The process of removing burrs, the small flakes of metal, is known as de-burring. Burr creation in machining accounts for a major part of the costs for manufacturers throughout the world. Drilling burrs, for example, are common when drilling almost any material. The Boeing 747 airplane has approximately 1.3 million holes drilled in it most of which have to be de-burred to some extent (Burrs-metal, April 2007). As one could imagine, the cost and time needed to perform these drilling and de-burring operations is significant.

In addition to drilling, milling is also a source of burr formation in machining. A good example of unwanted burrs is in the automotive industry where cylinder blocks, pistons and other engine components are cast then milled to a specific dimension. With higher demands placed on accuracy and precision, burr formation is of critical importance because it can affect engine performance, reliability, and durability。

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Alternate '01 Tungsten Dart out ChartⅠ

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 17:31

There are many different combinations of numbers you can use to successfully double-out in an tungsten dart ’01 game. Here are some alternate out number combinations:

Legend: S= Single, D= Double, T= Triple, SB= Single Bull, DB= Double Bull

164 Out

T19 + T19 + DB (57 + 57 + 50)

154 Out

T19 + T19 + D20 (57 + 57 + 40)

150 Out

T20 + DB + D20 (60 + 50 + 40)

148 Out

T20 + T20 + D14 (60 + 60 + 28)

146 Out

T19 + T19 + D16 (57 + 57 + 32)

145 Out

T20 + T19 + D14 (60 + 57 + 28)

144 Out

T18 + T18 + D18 (54 + 54 + 36)

T20 + T16 + D18 (60 + 48 + 36)

142 Out

T20 + T18 + D14 (60 + 54 + 28)

T20 + DB + D16 (60 + 50 + 32)

141 Out

T17 + T18 + D18 (51 + 54 + 36)

140 Out

T20 + T16 + D16

139 Out

T19 + T18 + D14 (57 + 54 + 28)

T20 + T19 + D11 (60 + 57 + 22)

T19 + DB + D16 (57 + 50 + 32)

135 Out

DB + T19 + D14 (50 + 57 + 28)

SB + T20 + DB (25 + 60 + 50)

DB + T15 + D20 (50 + 45 + 40)

SB + T20 + DB (25 + 60 + 50)

134 Out

DB + T14 + D20 (50 + 42 + 40)

T20 + T20 + D6 (60 + 60 + 12)

T20 + T16 + D12 (60 + 48 + 24)

T20 + T12 + D18 (60 + 36 + 36)

DB + DB + D16 (50 + 50 + 32)

131 Out

T19 + T14 + D16 (57 + 42 + 32)

130 Out

T20 + T20 + D5 (60 + 60 + 10)

S20 + T20 + DB (20 + 60 + 50)

T20 + T10 + D20 (60 + 30 + 40)

129 Out

S19 + T20 + DB (19 + 60 + 50)

128 Out

S18 + T20 + DB (18 + 60 + 50)

T18 + T18 + D10 (54 + 54 + 20)

S18 + T20 + DB (18 + 60 + 50)

127 Out

T20 + 17 + DB (60 + 17 + 50)

S20 + T19 + DB (20 + 57 + 50)

126 Out

T19 + S19 + DB (57 + 19 + 50)

125 Out

DB + T17 + D12 (50 + 51 + 24)

DB + SB + DB (50 + 25 + 50)

T18 + T13 + D16 (54 + 39 + 32)

S18 + T19 + DB (18 + 57 + 50)

124 Out

S20 + T18 + DB (20 + 54 + 50)

T20 - S14 – DB (60 + 14 + 50)

123 Out

T19 + T16 + D9 (57 + 48 + 18)

T19 + S16 + DB (57 + 16 + 50)

S19 + T18 + DB (19 + 54 + 50)

122 Out

T18 + T18 + D7 (54 + 54 + 14)

T18 + S18 + DB (54 + 18 + 50)

121 Out

T20 + T11 + D14 (60 + 33 + 28)

T20 + S11 + DB (60 + 11 + 50)

S20 + T17 + DB (20 + 51 + 50)

119 Out

S19 + T20 + D20 (19 + 60 + 40)

T19 + T12 + D13 (57 + 36 + 26)

T19 + S12 + DB (57 + 12 + 50)

118 Out

S20 + T20 + D19 (20 + 60 + 38)

T18 + S14 + DB (54 + 14 + 50)

117 Out

S20 + T19 + D20 (20 + 57 + 40)

S19 + T20 + D19 (19 + 60 + 38)

116 Out

S20 + T20 + D18 (20 + 60 + 36)

T19 + S19 + D20 (57 + 19 + 40)

S19 + T19 + D20 (19 + 57 + 40)

115 Out

S19 + T20 + D18 (19 + 60 + 36)

114 Out

S20 + T18 + D20 (20 + 54 + 40)

S18 + T20 + D18 (18 + 60 + 36)

113 Out

S20 + T19 + D18 (20 + 57 + 36)

T19 + S16 + D20 (57 + 16 + 40)

S19 + T18 + D20 (19 + 54 + 40)

112 Out

T18 + S18 + D20 (54 + 18 + 40)

T19 + S19 + D18 (57 + 19 + 36)

111 Out

T19 + S14 + D20 (57 + 14 + 40)

110 Out

T17 + S20 + D20 (51 + 20 + 40)

S16 + T18 + D20 (16 + 54 + 40)

109 Out

S19 + T18 + D18 (19 + 54 + 36)

T20 + S17 + D16 (60 + 17 + 32)

S20 + T19 + D16 (20 + 57 + 32)

T19 + S20 + D16 (57 + 20 + 32)

108 Out

T18 + S18 + D18 (54 + 18 + 36)

T20 + S16 + D16 (60 + 16 + 32)

T20 + S8 + D20 (60 + 8 + 40)

S20 + T20 + D14 (20 + 60 + 28)

S20 + T16 + D20 (20 + 48 + 40)

T17 + S17 + D20 (51 + 17 + 40)

107 Out

S20 + T17 + D18 (20 + 51 + 36)

T19 + S18 + D16 (57 + 18 + 32)

S19 + T20 + D14 (19 + 60 + 28)

S19 + T16 + D20 (19 + 48 + 40)

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Heavy Alloys Army Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 16:58

Tungsten heavy alloys have very high melting point and have a density twice that of steel and are more than 50% heavier than lead. Due to their high density, tungsten heavy alloys offer greater radiation shielding than lead and are non-toxic. Tungsten alloys are electrically and thermal conductive and offer good corrosion resistance. They also have a low coefficient of expansion and have a high modulus of elasticity.

Because of these unique properties tungsten heavy alloys are used extensively in military applications. The Army uses of powder metallurgy extend from the conventional press and sinter to the more exotic processes of liquid phase sintering of tungsten heavy alloys and powder injection molding. The Navy has taken great advantage of tungsten heavy alloys by employing them in the phalanx close-in weapon system. The Army intends that research will lead to an alloy or composite of tungsten, when used as a long rod penetrator, will perform as well as, or better than, current depleted uranium penetrators. Tungsten heavy alloys are the best choice when designers in defense industries. Tungsten heavy alloys are the ideal material which combines high density, good mechanical strength and which is easily machined, tungsten alloy for military defense is very important.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing VI

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 16:30

Angular Contact Tungsten Carbide Ball Bearings: Angular contact tungsten carbide ball bearings use axially asymmetric races. The raceways in the inner and outer rings have a raised shoulder which is displaced with respect to each other in the direction of the bearing axis. (See angular contact tungsten carbide ball bearing photo below).

In simpler terms, this means that these bearings are designed to accommodate combined loads (loads in both the radial and axial directions). The angle of contact is the same on both the inner and outer race. The larger the contact angle, the higher the axial load supported, but the lower the radial load.

In New York Ruling (NY) R04120, dated June 26, 2006, angular contact ball bearings are defined as “having internal contact angles that generally range between 15-40 degrees and are designed to support both radial and axial loads where the axial load would normally exceed the design limits of a typical radial ball bearing.”

These bearings are found in automobiles, bicycles, turbines, jet engines, dentistry equipment, etc. The ten digit classification is dependent on whether the bearing is used in a wheel hub unit and whether the wheel hub unit is flanged.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

http://news.chinatungsten.com/en/tungsten-information/78843-ti-10039

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com