Basic Applications of Tungsten Carbide BurrsⅠ

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 15:28

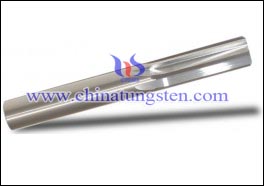

Tungsten carbide burrs are used for rapid removal of excess materials. Ironically, burrs are both referred to as the excess shavings of material and the actual carbide burr tools used to remove rough edges after the machining process. The removal of burrs from jagged, sharp edges is another common application for carbide burrs. In addition, carbide burrs are a supplemental type of tool that is used prior to polishing or finishing with coated abrasives. Tungsten carbide burrs can be used on cast iron, steel and aluminum. Depending on the type of surfaces that are accessible, carbide burrs can be utilized because of the different shapes in which they are manufactured. Typically, carbide burrs are made in inch diameter shapes such as round, cylindrical and oval. Carbide burrs are created with different cuts. Single or double cuts are used for steel and cast iron surfaces. According to Monroe (1997, p. 28), a course single cut minimizes the tendency of the cutter to load up with aluminum.

A die grinder is a handheld tool which turns a burr at a high rate of speed. It is usually pneumatic (powered by compressed air), although electric die grinders are also common. The burr is held in a bit holding device and may be changed as required. The rotational speed of a pneumatic die grinder is adjusted by a hand-operated throttle which allows the operator to fluctuate the volume of compressed air entering the tool. Die grinders are used to drudge away small amounts of metal from piece of work. The name comes from their use in touching up hardened steel dies.

Most die grinder throttles feature a spring-loaded “kickstand” mechanism between the throttle lever and the body of the grinder, which prevents the throttle from opening (being pressed down towards the body of the grinder) without operator intervention. This prevents the die grinder from accidentally activating.

(----to be continued. This article is divided into 2 parts and here is part 1.For part 2 please refer to: http://news.chinatungsten.com/en/tungsten-information/78879-ti-10049)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com