Tungsten Carbide Ball Bearing V

- Details

- Category: Tungsten Information

- Published on Tuesday, 22 September 2015 16:24

Linear Tungsten Carbide Ball Bearings: Linear tungsten carbide ball bearings are ball bearings designed to support loads that move along a straight line, rather than rotating about an axis. Linear tungsten carbide ball bearings usually consist of an outer ring, a ball retainer, balls and two end rings. The tungsten carbide linear ball bearing is designed so that balls roll directly on the surface along which the bearing moves.

These bearings provide increased precision and greater longevity than do simple sliding bearings. They are easy to install or replace and usually require minimum maintenance.

Tungsten carbide linear ball bearings are occasionally referred to as linear guides and are widely used in precision machinery, medical instruments, agricultural equipment and automated production equipment.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Dart Out Chart for 301, 501 And 801 Dart Games Ⅱ

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 17:34

Know your out chart like the back of your hand!

There are many different combinations of numbers you can use to successfully double-out in an ’01 tungsten dart game.

Legend: S=Single, D=Double, T=Triple, SB=Single Bull, DB=Double Bull

127 Out

T20 + T17 + D8 (60 + 51 + 16)

126 Out

T19 + T19 + D6 (57 + 57 + 12)

125 Out

SB + T20 + D20 (25 + 60 + 40)

124 Out

T20 + T14 + D11 (60 + 42 + 22)

123 Out

T19 + T14 + D12 (57 + 42 + 24)

122 Out

T20 + T18 + D4 (60 + 54 + 8)

121 Out

T18 + T17 + D8 (54 + 51 + 16)

120 Out

T20 + S20 + D20 (60 + 20 + 40)

119 Out

T19 + T10 + D16 (57 + 30 + 32)

118 Out

T20 + S18 + D20 (60 + 18 + 40)

117 Out

T20 + S17 + D20 (60 + 17 + 40)

116 Out

T20 + S16 + D20 (60 + 16 + 40)

115 Out

T19 + S18 + D20 (57 + 18 + 40)

114 Out

T20 + S14 + D20 (60 + 14 + 40)

113 Out

T20 + S13 + D20 (60 + 13 + 40)

112 Out

T20 + S20 + D16 (60 + 20 + 32)

111 Out

T20 + S19 + D16 (60 + 19 + 32)

110 Out

T20 + S18 + D16 (60 + 18 + 32)

109 Out

S9 + T20 + D20 (9 + 60 + 40)

108 Out

T19 + S19 + D16 (57 + 19 + 32)

107 Out

T20 + S15 + D16 (60 + 15 + 32)

106 Out

T20 + S14 + D16 (60 + 14 + 32)

105 Out

T19 + S8 + D20 (57 + 8 + 40)

104 Out

T18 + S10 + D20 (54 + 10 + 40)

103 Out

T17 + S12 + D20 (51 + 12 + 40)

102 Out

T19 + S13 + D16 (57 + 13 + 32)

101 Out

T17 + S10 + D20 (51 + 10 + 40)

100 Out

T20 + D20 (60 + 40)

99 Out

T19 + S10 + D16 (57 + 10 + 32)

98 Out

T20 + D19 (60 + 38)

97 Out

T19 + D20 (57 + 40)

96 Out

T20 + D18 (60 + 36)

95 Out

T19 + D19 (57 + 38)

94 Out

T18 + D20 (54 + 40)

93 Out

T19 + D18 (57 + 36)

92 Out

T20 + D16 (60 + 32)

91 Out

T17 + D20 (51 + 40)

90 Out

T18 + D18 (54 + 36)

89 Out

T19 + D16 (57 + 32)

88 Out

T16 + D20 (48 + 40)

87 Out

T17 + D18 (51 + 36)

86 Out

T18 + D16 (54 + 32)

85 Out

T15 + D20 (45 + 40)

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Points for Correct Using Cemented Carbide Drill BitsⅡ

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 17:34

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Points for Correct Using Cemented Carbide Drill BitsⅠ

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 17:10

(This article is divided into 2 parts, and here is Part 1.For part 2, please refer to:http://news.chinatungsten.com/en/tungsten-information/78808-ti-10037)

----To be continued----

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing IV

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 16:34

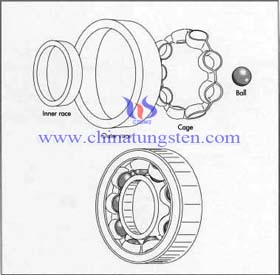

Thrust Ball Bearings: A thrust ball bearing, as shown to the right, is a particular type of rotational bearing, and like other rotational bearings, permits rotation between two moving parts. These bearings are comprised of balls and washer like bearing rings. The rings may have flat rolling surfaces with no defined raceway or may have contoured rolling tracks (grooved race or washer) that together with a cage assembly hold the balls in place.

Thrust ball bearings are designed to support axial loads, which are loads applied along the axis of the bearing, as opposed to radial loads, which are applied perpendicular to the axis of the bearing. This type of bearing is found in various items including swivel barstools, turntables, and construction equipment.

Generally, there are three types of thrust bearings: flat-race thrust bearings which consist of flat washers and have a limited load capacity; single-direction thrust bearings, which consist of grooved races and which support axial loads in one direction; and double-direction thrust bearings, which consist of two grooved races and which can accommodate axial loads acting in both directions. Thrust bearings can also incorporate rollers (thrust roller bearings) as a means to reduce friction.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing III

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 16:30

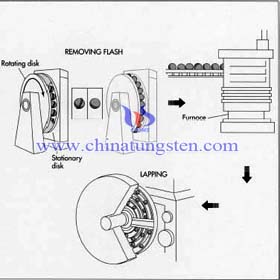

There are twomain sections of tungsten carbide ball bearing, one is ball bearings with integral shafts, the other is specifically divided into thrust bearings, linear bearings, angular contact bearings and the most common ball bearing, the radial bearing.

2. Ball Bearings without Integral Shafts

Unground Ball Bearings: An unground ball bearing is a bearing in which the races have not been subjected to a grinding operation during production. The surfaces of unground bearings are often formed by stamping or drawing and are usually not subject to the surface hardening processes to which ground bearings are subjected. Unground bearings are usually of less precision than a ground bearing and are usually distinguished by their dull finish. Unground bearings are often used in bicycles, lawn mowers, shopping carts and other less demanding applications.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

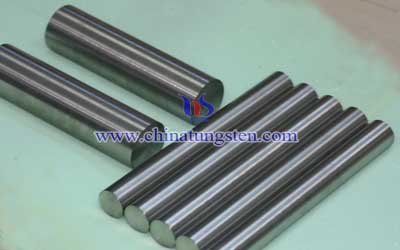

Tungsten Alloy Swaging Rod

- Details

- Category: Tungsten Information

- Published on Monday, 21 September 2015 15:13

Tungsten alloy rod is one of the most popular material for military, with the development of swaging technology,tungsten alloy military swaging rod play a significant role in military defense,such as depleted uranium kinetic energy penetrators, bullet, armor piercing, armor piercing bullets, sniper rifle penetrator, etc.

Main Processing of Tungsten Alloy Swaging Rod:

1). Mixing

2). Pressing

3). Sintering

4). Heat treatment

5). Swaging

6). Machining

After swaging the ultimate tensile strength of tungsten alloy rod greatly increases. The ultimate tensile strength of regular tungsten alloy rod is 1050 MPa . However, after swaging, the ultimate tensile strength can reach 1250 MPa min, and now the ultimate tensile strength even can control at 1450 MPa.

Tungsten Alloy Swaging Rod Main Properties for Military :

* High density

* High melting point

* Small volume

* Excellent hardness

* Superior wearing resistance

* High ultimate tensile strength

* High ductility

* High temperature resistance

* Low vapor pressure

During the World War Ⅱ, tungsten has already been used as an important raw material for military defense. There were abundant wolfram ore reserves found then in Portugal, which were used to produce tungsten concentrates for military defense.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅺ

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 18:59

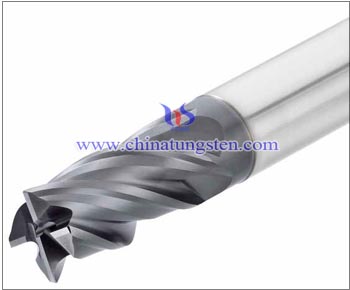

In last part we have experiments showing that the tool life of TiN-coated tool with Co interlayer was improved to 36% compared to the TiN-coated tools, and all data analysis verified that the tool wear distributions for each cutting time represent the distribution where the normal distributions and log-normal distributions are consistent. And in earlier parts we have talked about how we prepare those experiments and what data have been got concerning the performance of tungsten carbide cutting tool’s with an extra layer between the substrate and the TiN coating. Here we will come to a final conclusion although this does not mean an end to the relative research work.

4. Conclusions

TiN and TiN with three kinds of Co interlayer coatings were applied to end-mill tools made of WC-Co material by hybrid coating technique. The thin Co interlayer having the critical thickness (0.027μm) enhanced the adhesion between TiN coating layer and WC-Co substrate. The highest critical load of approximately 84 N was obtained for the TiN coating with Co interlayer thickness of 0.027μm. The critical scratch load was strongly dependent on the thickness of Co interlayer. The tool life of TiN-coated tool with Co interlayer having the critical thickness of 0.027μm was improved by over 36% compared to TiN-coated tools. From the test of goodness of fit, all experimental data were within the range of ± 3σ. The flank wear of TiN-coated tool with Co interlayer at a given cutting time is suitable for normal distribution and log-normal distribution by chi-squared test.

(This article is totally divided into 11 parts and here is part 11, for part 10 please read: http://news.chinatungsten.com/en/tungsten-information/78775-ti-10028)

------END-------

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅹ

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 18:35

In last part, we find that as post-annealing temperature increases, the critical load value continually increased even after post-annealing at 600 °C for 2 h due to heat treatment’s improvement of adhesion property of co interlayer to the tungsten carbide substrate. Here we talk about cutting performance and reliability verification.

3.2. Cutting performance and reliability verification

In general, the wear of tungsten carbide cutting tool is a result of the load, friction and temperature between the cutting edge and the work piece. When higher cutting temperatures are reached, the cutting tool edge can easily lead to chipping and cracking. Accordingly, the wear mechanism in high-speed machining largely depends on the cutting conditions and the tool properties.

Cutting tests against AISI D2 die steel and their reliability tests were studied. In order to evaluate cutting performance of end-mill tool under high-speed cutting condition, four kinds of coating tools, TiN and TiN with Co interlayer thickness of 0.027μm, 0.08μm, and 0.15μm were evaluated. Experiments show that as the cutting times increased, the tool wear increases proportionally. As expected, the wear curve of TiN-coated tool with Co interlayer thickness of 0.027μm slightly increased. The tool life of TiN-coated tool with Co interlayer was improved to 36% compared to the TiN-coated tools. This trend seemed to be due to higher toughness, i.e. a better adhesion between coating layer and substrate.

The best TiN-coated tool with Co interlayer thickness of 0.027μm was tested 18 times repeatedly until the flank wear reaches over 300μm using. The mean value and standard deviation of tool wear values are small at the initial stage of cutting but they get larger with the lapse of time. To verify the goodness of fit for tool wear distribution, the normal distribution, log-normal distribution, and the Weibull distribution, with the shape coefficient are between 0.5 and 5, were used in this work. The probability density functions of the normal distribution f1(t), log-normaldistribution f2(t), and Weibull distribution f3(t) can be expressed as follows:

Using the Minitab software (Minitab, Ver14), which is one of the general-purpose statistical computing systems, the probability density of each distribution was calculated from the experimental data for each cutting time. All experimental data were within the range of ± 3σ. The experiments were performed under the same conditions and a χ2 test verified that the tool wear distributions for each cutting time represent the distribution where the normal distributions and log-normal distributions are consistent.

(This article is totally divided into 11 parts and here is part 10, for part 9 please read: http://news.chinatungsten.com/en/tungsten-information/78776-ti-10030 )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Run a Tungsten Dart Ladder

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 17:12

First, make a list of people that would like to participate. After doing this, you can then decide as a group how many weeks that this will run and the number/format of games to be played. Names are then picked at random and placed in the tungsten dart ladder from top-to-bottom, the top being the person in first place. It will look something like this: John Doe, Jim Smith, Sue Smith, etc.

Each week, the person in first will play the person in second, the person in third will play the person in forth and so on. The two participants can play at their own convenience at the location of their choice. The format can vary depending on the games you want to play and the total games to be played. Let's say that it will consist of 5 games of 501 and 6 games of cricket for a total of 11 games.

Each week, everyone reports the number of games that they had won and those points are accumulated and the people in the tungsten dart ladder are then re-ranked by the number of points they have. In case of a tie, the person that was ranked highest the prior week will continue to be ranked higher. This will continue until the last week's matches have been played when a champion will be crowned.

Now, you can do this for fun or for money. The participants can pay a fee up front or even a weekly fee that will go into a pot and will be distributed at the end. How much and how it is distributed should be decided by the group prior to the tungsten dart ladder being drawn up. Ladders just played for fun and bragging rights not only can be more fun, but will most likely involve more people. Many people aren't willing to throw away their money if they do not feel like they have a chance to win. But these same people will be more than willing to play for free.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com