Types of Tungsten Carbide End Mills and DiagramsⅠ

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 September 2015 17:32

There are many types of tungsten carbide end mills, such as back corner rounding end mills, ball end mills, etc., and here we list these types with their respective diagrams so that the beginners are easy to learn about them.

(To be continued. This article is divided into several parts and this is part 1, for part 2 please refer to:http://news.chinatungsten.com/en/tungsten-information/79096-ti-10095)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Challenge Tungsten Dart Ladder

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 September 2015 17:28

Challenge tungsten dart ladder is yet another type of tungsten dart ladder. It is organized and played the same way with the following exception, players challenge their opponents to a match as opposed to one playing two, three playing four, etc. You can challenge either of the two people immediately above you (the person in 5th place can challenge either the person in 4th or the person in 3rd, nobody else). If you win, you take their position. If you lose, you stay where you are. You do not keep track of the number of wins each player has but all players must play one match/week. Once a player has been challenged, he/she can not challenge anyone else for that week. So it's first come, first serve. Get your challenge in as soon as possible so that you will have a chance to move up, instead of having to play to hold the position you're already holding. This can get a bit confusing and you can alter the rules in any fashion you deem necessary. One way to make this clearer is to let the lowest ranking person challenge first, then continue to work up the tungsten dart ladder until everyone has a match to play.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Description

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 September 2015 17:23

Tungsten copper electrode is kind of composite metal material and is composed of high purity tungsten powder and good conductivity Cu powder through isostatic pressing and high temperature sintering. Therefore, tungsten copper electrode not only has high melting point(3410℃) and high density (19.34 g/cm3) of W, but also has good conductivity and other advantages of Cu.

|

Property |

Density(g/cm3) |

Thermal expansion coefficient(10-3/℃) |

Thermal conductivity(w/(m·k)) |

Heat Capacity(j/(kg·℃)) |

Elastic Modulus(GPa) |

Poisson density |

Melting point(℃) |

Strength(MPa) |

|

W |

19.32 |

4.5 |

174 |

136 |

411 |

0.28 |

3410 |

550 |

|

Cu |

8.96 |

16.6 |

403 |

385 |

145 |

0.34 |

1083 |

120 |

In addition, tungsten copper has good thermal resistance, high thermal conductivity and low expansion, which can be partly used in resistance welding or electrical contacts. EDM and EDM is the most widely used tungsten copper as electrodes.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Copper-tungsten Electrode Influencing Factor

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 September 2015 17:21

Due to the high thermal conductivity of Cu, and the better spark erosion resistance, low thermal expansion coefficient and high melting temperature of W, copper-tungsten electrodes have been widely used for machining die steel and tungsten carbide work-piece. The materials normally used in EDM electrodes are various types of copper, graphite, tungsten, brass and silver. But copper-tungsten has better properties. The low melting point of Cu reduces the resistance to electrode wear.

At high tungsten content, there is porosity in the liquid phase sintered electrode due to the insolubility between the Cu and W. This greatly impedes densification during the solution-reprecipitation stage of liquid phase sintering. Hence, this makes it necessary to introduce another material with high melting point. Materials having good electrical and thermal conductivity with a high melting point are used preferably in copper-based electrodes to resist electrode shape-loss.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Army Applications

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 September 2015 16:31

In World War II, projectiles made from tungsten alloys helped Allied forces achieve victory. Today, high-density tungsten alloys are still proving their worth in army applications around the world. The uncompromising strength found in tungsten alloys allows it to offer the highest quality in hyper-velocity, armor-penetrating applications, fragmentation devices and kinetic energy penetrators (in spheres, cubes and projectile shapes).

Tungsten has the highest melting point among all melts. The prominent advantage of high melting point is it produces materials with good high temperature strength and corrosion-resistance, which shows its excellent properties in army industry, especially in ordnance components manufacturing. With powder preprocessing technique and large deformation enhancement technique, tungsten alloys are refined to grains to increase the durability and penetrating force of materials.

There are some typical products made from tungsten:

Balanced ball for missile and plane

Core for armor-piercing shell

Tungsten alloy cluster bomb

Tungsten alloy gyro-rotor for airplane

Bullet of grenade

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Types of Carbide Bur Shanks Ⅲ

- Details

- Category: Tungsten Information

- Published on Monday, 28 September 2015 18:34

In last part we read The type of tungsten carbide bur shank FG long has the same diameter as a standard friction grip bur but the length is longer and used for high speed hand pieces, while type FG surgical has similar feature but is used when a longer length and better visibility are required.. Here we describe types “RA”, “RA surgical” and “HP”.

(the END. This article is divided into 3 parts and this is part 3, for part 2 please refer to: http://news.chinatungsten.com/en/tungsten-information/79027-ti-10080)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

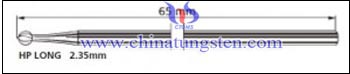

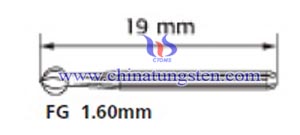

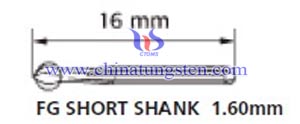

Types of Carbide Bur ShanksⅡ

- Details

- Category: Tungsten Information

- Published on Monday, 28 September 2015 18:29

In last part we read The three main types of tungsten carbide bur shanks are Friction Grip (FG), Right Angle (RA), and Hand piece (HP), and it is important to know their designed task, for example, FG type having smallest shank diameter and most commonly used, and FG SS used when better access to the posterior region is needed. Here we describe types “FG long” and “FG surgical”.

(To be continued. This article is divided into 3 parts and this is part 2, for part 1 please refer to: http://news.chinatungsten.com/en/tungsten-information/79006-ti-10076; and for part 3 please refer to : http://news.chinatungsten.com/en/tungsten-information/79028-ti-10081)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode for EDM

- Details

- Category: Tungsten Information

- Published on Monday, 28 September 2015 17:56

Electric discharge machining (EDM) is a non-traditional type of precision processing using an electrical spark-erosion process between the electrode and the working piece of electrically conductive immersed in a dielectric fluid. Since it has more special gains, the EDM has been widely applied in modern metal industry for producing complex cavities in moulds and dies, which are difficult to manufacture by conventional machining.

The use of Electrical Discharge Machining in the production of forming tools to produce plastics moldings, die castings, forging dies etc., has been firmly established in recent years. The EDM is a well-established machining choice for manufacturing geometrically complex or hard material parts that are extremely difficult to machine by conventional machining process. Its unique feature of using thermal energy to machine electrically conductive parts regardless of hardness has been its distinctive advantage for manufacturing of mold, die, automotive, aerospace and surgical components. Thus, titanium and titanium alloy, which is difficult-to-cut material, can be machined effectively by EDM.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Types of Carbide Bur ShanksⅠ

- Details

- Category: Tungsten Information

- Published on Friday, 25 September 2015 18:40

The three main types of shanks are Friction Grip (FG), Right Angle (RA) (also known as Latch-Type), and Hand piece (HP). It is important to know which type of shank you want when choosing a bur because each type is designed to fit into a certain type of hand piece.

(To be continued. This article is divided into 3 parts and this is part 1)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Major Difference between Tungsten Carbide Burs and Diamond Burs

- Details

- Category: Tungsten Information

- Published on Friday, 25 September 2015 18:18

Many countries impose stricter import regulation for ISO 13485 and ISO 9001:2008 approved Burs and has regular checks on the factories conformity to these ISO Standards. Prices of most basic manufacturing process have steadily increased since 3 years back. Diamond powder has increased since with over 300% and nickel block has increased also over 150% with increases to other electrolyte chemicals, labor cost and fixed overhead cost too. The price for Diamond Burs will surely be increased in it export price in due course of time. Dental carbide burs are feature an extra coarse, coarse, double cut, fine, medium fine and super fine pattern. The carbide burrs are specialized drill bit used in industry. There are some special needs that must be addressed in the design and manufacture of carbide burrs, including re-sharpening facility with a complete line of standard carbide burs as well as endless custom carbide burrs requirements. As a consequence of these different decreases in CR with longer cutting times, the super–coarse-grit diamond burs cut faster than the medium-grit diamond burs for Cut 3 (P < .05), while there was no difference in CR between the coarse-grit diamond burs and super–coarse-grit diamond burs (P > .05). When we compared the overall CRs, we found that the super–coarse-grit diamond burs cut faster than the medium-grit diamond burs (P < .01), but there was no difference in CR (P > .05) between coarse-and super–coarse-grit diamond burs over the cutting procedure.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com