Tungsten Copper Electrode and Other Materials Comparison V

- Details

- Category: Tungsten Information

- Published on Thursday, 15 October 2015 15:43

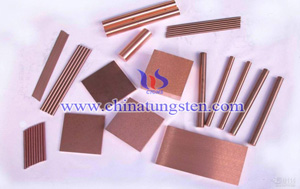

Tungsten copper (Cu-W) not only has high melt point, low coefficient of expansion and spark resistance, but also has good conductivity so that it is a new kind of high-performance electrode material. Tungsten copper electrode is widely used in die steel and WC work-pieces, the common ratio of Cu/W is 25:75. However, the higher price than graphite or copper, tungsten copper spreading has been blocked to some extent.

Some researchers use copper, tungsten copper, brass and aluminum as electrode for hardened steel machining. The result shows that Cu and Al have higher speed and better precision, Cu and tungsten copper (W-Cu) has the lowest electrode wastage and brass electrode wastage is the largest. Therefore, Cu is a kind of ideal electrode for hardened steel machining, which has low wastage of electrode and high MRR (Material Removal Rate).

More information about tungsten copper electrode and other materials comparison, click here:

http://news.chinatungsten.com/en/tungsten-information/79286-ti-10093

http://news.chinatungsten.com/en/tungsten-information/79316-ti-10129

http://news.chinatungsten.com/en/tungsten-information/79338-ti-10130

http://news.chinatungsten.com/en/tungsten-information/79339-ti-10131

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide Cutters Ⅶ

- Details

- Category: Tungsten Information

- Published on Thursday, 15 October 2015 14:56

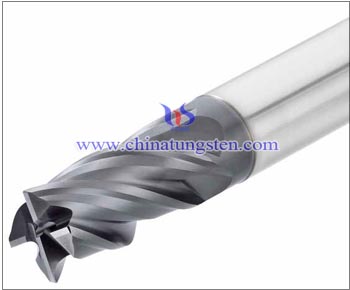

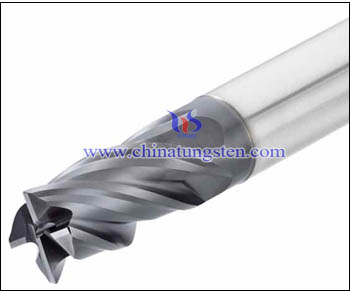

In part 6 we know that catering failure happens when the tungsten carbide cutter’s surfaces are stricken by particulate-bearing liquid or gas, especially when the operating temperatures are much higher and the more fine-grained the carbide is, the easier for the failure to occur.. In this part we will talk about adhesion wear/galling as another failure mode.

7. Adhesion wear/galling

Adhesion wear occurs when a tungsten carbide cutter’s surface and that of a mating part or the work material rub together or slide past each other with sufficient force to create excessive friction and pressure at high points of contact between the materials. The high temperatures and pressures generated in these contact zones result in plastic deformation at the material surfaces, penetration of one surface by the high points on the other, and finally the transfer of material (welding) of one material to the other. As material builds up on one of the surfaces, the still higher points of contact create more heat, leading to more deformation, penetration, and material transfer. This process is often referred to as “galling”. Failure by adhesion wear can take several forms, but typically the buildup reaches a stage where it eventually is dislodged pulling chunks of the carbide surface with it.

(To be continued. This article is divided into 9 parts and this is part 7, for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/79384-ti-10152)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide Cutters Ⅵ

- Details

- Category: Tungsten Information

- Published on Thursday, 15 October 2015 14:52

In part 5 we know that although carbide material is hard, tungsten carbide cutters can still deform plastically due to a high enough temperature to soften the binder metal, and such a tiny thermal deformation can result in the function failure of assembly tools. In this part we will talk about cracking which is also one of the most common failure modes of tungsten carbide cutters.

6. Cratering failure

Failure known as “cratering” is a localized form of erosion in which a depression develops at the point where a continuous stream of metal or particulate-bearing liquid or gas strikes the working surface of the tungsten carbide cutter’s component. At operating temperatures high enough to soften the binder metal (those exceeding about 900° C.) cratering can take place rapidly. Very fine-grained carbides are particularly susceptible to cratering since smaller grains are locked into the carbide surface by a relatively thin layer of binder metal. As the crater increases in size and depth the carbide is weakened to the point where normal operating stresses produce mechanical failure in the area of the crater.

(To be continued. This article is divided into 9 parts and this is part 6, for part 5 please refer to http://news.chinatungsten.com/en/tungsten-information/79348-ti-10146 ; for part 7 please refer to http://news.chinatungsten.com/en/tungsten-information/79387-ti-10153)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten-based bucking bar

- Details

- Category: Tungsten Information

- Published on Thursday, 15 October 2015 11:42

The tungsten-based bucking bar has one or more smooth surface which is held up against the back of a rivet while it is being shot. The energy gets transferred from the source (the rivet gun) through a medium (the rivet) to the receiver (the bucking bar). The gun is on one end, and the bucking bar is on the other. The gun impacts the rivet, which sends the impulse to the bucking bar, which actually bounces off the rivet and "swings" back at it (by virtue of the person holding it firmly in place), smashing the rivet in turn. This happens many times per second - depending on air pressure and trigger operation. The primary skill required when bucking rivets is to hold the bucking bar stable and square to the rivet. Other than that, just let physics do the work. You don’t have to push on the rivet, just hold it steady.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Anti-material Rifle Bullet

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 October 2015 11:55

Tungsten alloy is a kind of composite materials that tungsten whose quality fraction is 80%-98% distributes to Ni-Fe-W sosoloid, as it is wished, tungsten alloy combines with the high density, high strength of tungsten and good ductility of matrix, so it has a series of properties of physics, chemistry and mechanics.

Tungsten alloy has wide usage in military industry with its good properties, one of applications is tungsten alloy anti-material rifle bullet, anti-material rifle continues the thinking of anti-tank rifle which was used in twice World War, it can launch large caliber machine gun bullet cooperating with anti-material rifle bullet, it can penetrate light tank which has thin armor, and kill personnel in the tank, it can also kill sniper hiding behind blindage mainly used for dealing with vehicles, oil depot, radar, telescopic surveillance mirror, copper flying at low altitude and jet landing on the ground.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide Cutters Ⅴ

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 October 2015 11:44

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide Cutters Ⅳ

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 October 2015 11:41

In part 3 we know that chipping/fracturing wear occurs to tungsten carbide cutter components when the service conditions are much tougher than carbide’s tolerance, especially when the cutting edges are unprotected, and so designs need consider to use protective edge chamfers and radii, avoiding sharp inside edges and other stress-inducing features. In this part we will talk about thermal cracking which is also one of the most common failure modes of tungsten carbide cutters.

4. Thermal Cracking

Cemented tungsten carbide cutters have relatively poor thermal shock resistance and sudden changes in temperature often produce failure by thermal cracking. Thermal cracks can result from thermal stresses developed in a single heating-cooling cycle if the temperature change is rapid and significant. These cracks often take the form of a network of fine cracks occurring throughout the bulk of the carbide component and normally result in catastrophic failure. Thermal cracks may also develop gradually over thousands of thermal cycles involving very small changes in temperature. The latter are more localized and typically occur as closely-spaced, radial cracks that extend from edges of the part. As the process progresses these cracks deepen and widen resulting in the spalling away of the carbide located between them.

(To be continued. This article is divided into 9 parts and this is part 4, for part 3 please refer tohttp://news.chinatungsten.com/en/tungsten-information/79331-ti-10139 ; for part 5 please refer tohttp://news.chinatungsten.com/en/tungsten-information/79348-ti-10146)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Head Shrapnel

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 October 2015 17:22

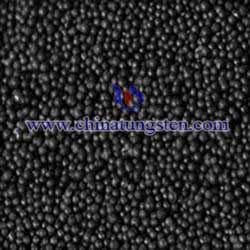

Tungsten alloy has so many properties such as: high density (60% higher than lead and much higher than steel), high radiation resistance, high temperature resistance, small volume and more. As these properties, tungsten alloy is progressively adopted since the raw substance to create components of army products, which include bullet, armor and shells, shrapnel head, grenade, hunting gun, bullet warheads. Head shrapnel relied almost entirely on the shrapnel velocity for head shrapnel lethality. The military use of head shrapnel has been obsolete since the end of World War I for anti-personnel use, when head shrapnel was superseded by high-explosive shells for that role. The functioning and principles behind head shrapnel shells are fundamentally different from high-explosive shell fragmentation.

Tungsten alloy head shrapnel is anti-personnel artillery munitions which carried a large number of individual bullets close to the target and then ejected them to allow head shrapnel to continue along the shell's trajectory and strike the target individually. The high density of tungsten alloy ball makes it possible to significantly reduce the physical size of tungsten alloy head shrapnel components. This in turn, gives the benefit of greater control of weight distribution and increases the sensitivity of controlling mechanisms.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode and Other Materials Comparison IV

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 October 2015 17:12

Some researchers put graphite electrode into molten metal (such as Cu or Al) in order to improve the properties of graphite electrode in EDM. At the same time, pressing the liquid metal and make Cu or Al fill in the pore of graphite electrode for improving the strength and thermal conductivity of the electrode.

Except graphite, Cu, Cu-based and Cu composite material is also widely used as electrode in EDM, ECM or other machining.

2. Cu, Cu-based and Cu Composite Material

Copper (commonly known as red copper), which is a kind of electrode material, especially in machining non-ferrous metal. Cu has low melting point so that its wastage is high, the lifespan is short and the cost too much, which requires that other material with high melt point to improve its properties.

More information about tungsten copper electrode and other materials comparison, click here:

http://news.chinatungsten.com/en/tungsten-information/79286-ti-10093

http://news.chinatungsten.com/en/tungsten-information/79316-ti-10129

http://news.chinatungsten.com/en/tungsten-information/79338-ti-10130

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode and Other Materials Comparison III

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 October 2015 17:08

Fine graphite has small grain, porosity and good mechanical strength, which has low wastage of electrode in EDM. But its MRR (Material Removal Rate) is undesirable. At present, the most of graphite grain size is below 10μm, which depends on the conditions electrode works (finishing, semi-finished or roughing) and its shape when we make a choice. In addition, the roughness of work-piece surface is related with the size of graphite grains, the average particle size below 1 μm is specialized for finishing.

Compared with other materials of electrode, graphite can be used in EDM with large discharge current, which remarkably increasing the efficiency. Although graphite has low proportion and price, it is too fragile to machining into the shape of thin. Therefore, it is limited in EDM and researchers find that high speed milling can be improved to some extent.

More information about tungsten copper electrode and other materials comparison, click here:

http://news.chinatungsten.com/en/tungsten-information/79286-ti-10093

http://news.chinatungsten.com/en/tungsten-information/79316-ti-10129

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com