Tungsten Carbide Reamer Ⅸ

- Details

- Category: Tungsten Information

- Published on Friday, 23 October 2015 17:22

In part 8 we know that a shell reamer is designed for reaming bearing or the similar with full length flutes, while a morse taper reamer is applied to finish morse taper sleeves which includes finishing reamers and roughing reamers. Here we explain combination reamer as another kind of tungsten carbide reamer.

A tungsten carbide combination reamer has two or more cutting surfaces. The combination reamer is precision ground into a pattern that resembles the part’s multiple internal diameters. The advantage of using a combination reamer is to reduce the number of turret operations, while more precisely holding depths, internal diameters and concentricity. Combination reamers are mostly used in screw machines or second-operation lathes, not with Computer Numerical Control (CNC) machines because G-code can be easily generated to profile internal diameters.

Combination reamers can be made out of cobalt, tungsten carbide, or high speed steel tooling. When using combination reamers to ream large internal diameters made out of material with lower surface feet per minute, carbide tips can be brazed onto a configured drill blank to build the reamer. Tungsten carbide reamer requires additional care because it is very brittle and will chip if chatter occurs. It is common to use a drill bit or combination drill to remove the bulk of material to reduce wear, or the risk of the part pulling off on the combination reamer.

(To be continued. This article is divided into several parts and this is part 9, for part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/79632-ti-10180;for part 10 please refer to http://news.chinatungsten.com/en/tungsten-information/79659-ti-10186)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 23 October 2015 17:02

Due to the increasing requirement of mould and intractable materials, tungsten copper has been widely used in electrode. Tungsten copper has many advantages, such as higher precision, lower wastage, high MRR (Material Removal Rate) as well as it can be finishing and roughing at one time. At the present, tungsten copper electrode plays an important role electrical discharge machining (EDM). According to incomplete statistics, Japan has 19.6 tons in tungsten copper electrode consumption in 1994 year, which accounts for a quarter of the aggregate consumption of tungsten copper (74.5 tons).

Except good conductivity, high MRR and easily to be machining, tungsten copper electrode is supposed to have:

1. Good arc ablation resistance.

2. Uniformity and Density.

3. Diverse shape and should be suited to small demands.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Properties

- Details

- Category: Tungsten Information

- Published on Friday, 23 October 2015 17:01

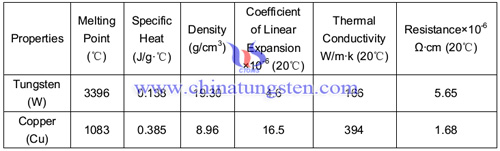

W and Cu Physical Properties

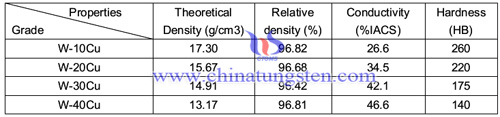

Tungsten Copper Electrode Properties (G38320-87)

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Military Applications

- Details

- Category: Tungsten Information

- Published on Friday, 23 October 2015 13:46

Tungsten, in Military applications, is used in bullets, as a hardening agent to produce armor penetrating rounds. It is also used for fragmentation to create a devastating effect as its hardness remains intact as it shreds through targets. Tungsten is also used in cube and ball form in anti-personnel ordnance, ranging from grenades, to mines and rockets, these added tungsten cubes and balls are highly destructive due to their retention of their hard, solid shapes as they impact. Tungsten alloys are also used in defensive plating, due to their hardness and strength. Tungsten carbide and other alloys are also used to make penetrators for weaponry, to enhance their effectiveness.

Another widely used application of tungsten in defense is the various weighting applications used in helicopters and other aircraft and armored vehicles. Helicopters often use this material to weight their rotors, noses, and skids. This metal is widely used in these applications because of its hardness and size to weight ratio it is a perfect material for weighting and protection.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Ⅷ

- Details

- Category: Tungsten Information

- Published on Thursday, 22 October 2015 18:17

In part 7 we know that rose reamer is secondarily used as softening tungsten carbide reamer and tapered reamer is used to make a tapered hole so that a tapered pin can be fixed in.And here we explain shell reamer and more taper reamer which are all tungsten carbide reamers.

(To be continued. This article is divided into several parts and this is part 8, for part 7please refer to http://news.chinatungsten.com/en/tungsten-information/79631-ti-10179)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Ⅶ

- Details

- Category: Tungsten Information

- Published on Thursday, 22 October 2015 18:16

(To be continued. This article is divided into several parts and this is part 7, for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/79554-ti-10174;for part 8 please refer to http://news.chinatungsten.com/en/tungsten-information/79632-ti-10180 )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Tungsten Powder Granularity on W-Cu Electrode IV

- Details

- Category: Tungsten Information

- Published on Thursday, 22 October 2015 17:23

Besides, according to the priority of the shortest distance, W grain will gather and come into being obturator when tungsten powder granularity is small. Due to the block and the unevenness of pores, the distance of electron is longer so that the conductivity decreases. On the contrary, the larger size of tungsten powder granularity distributes more uniformly, fewer pores left so that the distance of electron is straight and the conductivity is better.

In conclusion, firstly, the finer tungsten powder will cause much Cu gathering and have an effect on the uniformity of tungsten copper. Secondly, with tungsten powder granularity decreasing, the density and hardness of tungsten copper (W-Cu) will be remarkably improved. Finally, tungsten powder granularity has a huge effect on the porosity and micro-structure of tungsten copper.

More information about the effect of tungsten powder granularity on W-Cu electrode, click here:

http://news.chinatungsten.com/en/tungsten-information/79564-ti-10150

http://news.chinatungsten.com/en/tungsten-information/79567-ti-10151

http://news.chinatungsten.com/en/tungsten-information/79625-ti-10156

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Tungsten Powder Granularity on W-Cu Electrode III

- Details

- Category: Tungsten Information

- Published on Thursday, 22 October 2015 17:21

Take tungsten copper W-30Cu as an example, it has more Cu than W-20Cu so that it has better conductivity. With the increasing granularity of tungsten powder, the electric resistance is decreasing and the conductivity is enhancing. On the contrary, the smaller tungsten powder, the greater electric resistance. Except tungsten powder granularity, there are many factors affect the conductivity of tungsten copper electrode, such as chemical composition, porosity, impurities, micro-structure (grain size, grain boundary strength, the distribution of high thermal conductivity of copper phase and W-W connectivity) and so on.

Compared with other factors, tungsten copper granularity has an effect on the conductivity by the porosity and micro-structure of tungsten copper electrode. On the one hand, tungsten copper electrode still has some pores, which can not be neglected. On the other hand, the smaller size of tungsten powder will reduce the completeness of Cu grid, which causes the insufficiency of copper solution.

More information about the effect of tungsten powder granularity on W-Cu electrode, click here:

http://news.chinatungsten.com/en/tungsten-information/79564-ti-10150

http://news.chinatungsten.com/en/tungsten-information/79567-ti-10151

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Tungsten Powder Granularity on W-Cu Electrode II

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 October 2015 16:53

Tungsten powder granularity has an effect on the density, the hardness and the electrical conductivity of tungsten copper electrode.

2. Effects on the Density and Hardness of Tungsten Copper Electrode

The experiment result shows that with the increasing powder granularity, the density of W70-Cu alloy is a trend of decreasing after infiltration. For instance, when tungsten powder granularity of W-30Cu is 2.65μm, the hardness is up to HB222. But the larger powder granularity, the lower hardness, and the lowest hardness is HB190 with 2.65 power granularity. The principle is that although tungsten has high density (19.3g/cm3), it belongs to fragile material. The finer power, the more active sintering, the more obviously shrinking of volume, which increases the content of W and improve the density and hardness of tungsten copper electrode.

More information about the effect of tungsten powder granularity on W-Cu electrode, click here:

http://news.chinatungsten.com/en/tungsten-information/79564-ti-10150

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Effect of Tungsten Powder Granularity on W-Cu Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 October 2015 16:48

Compared with other electrode, tungsten copper electrode has many advantages, such as high quality, high efficiency, low wastage and high MRR (Material Removal Rate), etc. Therefore, tungsten copper electrode is suitable for rotating speed mold and finish of hard to processing material. At present, the most literatures are focused on the influence of processing, including W skeleton, density, hardness and uniformity on tungsten copper electrode, but this paper is inclined to discuss that tungsten powder granularity effects.

1. Effects on the Tissue of Tungsten Copper Electrode

The experiments result shows that the finer of tungsten powder, the more uniformly W powder distributes and the much more possibility of weakness and pores. On the contrary, the larger size of tungsten grain, the lower dispersion and the fewer pores left.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com