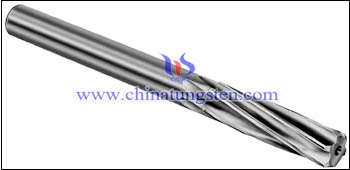

Tungsten Carbide Reamer Ⅵ

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 October 2015 14:44

In part 5 we know that straight reamers are used to enlarge a hole in small scale with a slight taper at one end and the length can be variable, and the reamed holes are typically used to any two locating parts where the locating accuracy is required within 0.02 mm. And here we explain hand reamer and machine reamer which are similar tungsten carbide reamers.

(To be continued. This article is divided into several parts and this is part 6, for part 5, please refer to http://news.chinatungsten.com/en/tungsten-information/79553-ti-10173)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Ⅴ

- Details

- Category: Tungsten Information

- Published on Wednesday, 21 October 2015 14:42

In part 4 we know that tungsten carbide reamers are used to enlarge or create a smooth surface finish to a hole already drilled since drilling followed by reaming generally produces hole geometry and finish that is as close to theoretical perfection as possible. And here we explain straight reamer.

Straight reamer

A tungsten carbide straight reamer is used to make only a minor enlargement to a hole. The entry end of the reamer will have a slight taper, the length of which will depend on its type. This produces a self centering action as it enters the raw hole. The larger proportion of the length will be of a constant diameter.

Reamed holes are used to create holes of precise circularity and size, for example with tolerances of -0/+0.02 mm(.0008") This will allow the force fitting of locating dowel pins, which need not be otherwise retained in the body holding them. Other holes, reamed slightly larger in other parts, will fit these pins accurately, but not so tightly as to make disassembly difficult. This type of alignment is common in the joining of split crankcase halves such as are used in motorcycle motors and boxer type engines. After joining the halves, the assembled case may then be line bored (using what is in effect a large diameter reamer), and then disassembled for placement of bearings and other parts. The use of reamed dowel holes is typical in any machine design, where any two locating parts have to be located and mated accurately to one another - typically as indicated above, to within 0.02 mm or less than .001".

Another use of reamed holes is to receive a specialized bolt that has an unthreaded shoulder - also called a shoulder bolt. This type of bolt is commonly used to replace hot peened rivets during the seismic retrofit of structures.

(To be continued. This article is divided into several parts and this is part 5, for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/79531-ti-10169;for part 6 please refer to http://news.chinatungsten.com/en/tungsten-information/79554-ti-10174)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Erosion Mechanism III

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 16:53

Tungsten powder re-sintering is can not be neglected when arcing. After Cu evaporating by pulsed arc, some W grains will be exposed in medium. This tungsten grains re-sintering and spheroidizing or transferring to the surface by surface effect at high temperature, which make the cracks expand inside skeleton inevitably. In general, tungsten copper will volatile and compound in high temperature arc, which the cracks is accelerating the erosion.

Those tiny pores left by Cu evaporating will become the source of the next cracks and the re-sintering accelerate cracks expanding. In addition, the oxides combine electrode contact with arc-blast medium and carbide is brittle so that they will be broken and spalling under mechanical impact until the electrode failed.

More infomation about tungsten copper electrode erosion mechanism, click here:

http://news.chinatungsten.com/en/tungsten-information/79477-ti-10142

http://news.chinatungsten.com/en/tungsten-information/79543-ti-10144

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Erosion Mechanism II

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 16:50

There are four kinds of tungsten copper processing, liquid phase sintering – repressing – re-sintering, solid phase sintering – repressing – re-sintering, infiltration – machining and pre-sintering tungsten (W) skeleton – melt dipping – machining. The last method is more popular currently, which make material has good mechanical properties. Because W grains is not longer individual in this process, which becomes firm tungsten skeleton after high temperature sintering. Therefore, this stable structure can endure the impact of machinery. Besides, the ability of resistance of cracks and expanding is much better in this way.

However, it is unavoidable that tungsten copper electrode also has weakness in structure. One is tungsten maybe has cracks, but it is unlikely. The other is more probable, which has pore in Cu when tungsten skeleton forming and condensation. Under high temperature and 10-times pressure, tungsten will emerge compressive stress, which will tear the cracks already exist. In addition, with the increasing of arc frequency, the stress of matrix enduring will enhance so that the cracks will expand and connected with cracks of surface outside.

More infomation about tungsten copper electrode erosion mechanism, click here:

http://news.chinatungsten.com/en/tungsten-information/79477-ti-10142

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Ⅳ

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 14:27

In part 3 we know that tungsten carbide reamers are used to enlarge or create a smooth surface finish to a hole already drilled since drilling followed by reaming generally produces hole geometry and finish that is as close to theoretical perfection as possible. And here we will show you some reamer types and first comes adjustable hand reamer.

Adjustable hand reamer

An adjustable hand reamer can cover a small range of sizes. They are generally referenced by a letter which equates to a size range. The disposable blades slide along a tapered groove. The act of tightening and loosening the restraining nuts at each end varies the size that may be cut. The absence of any spiral in the flutes restricts them to light usage (minimal material removal per setting) as they have a tendency to chatter. They are also restricted to usage in unbroken holes. If a hole has an axial split along it, such as a split bush or a clamping hole, each straight tooth will in turn drop into the gap causing the other teeth to retract from their cutting position. This also gives rise to chatter marks and defeats the purpose of using the reamer to size a hole.

(To be continued. This article is divided into several parts and this is part 4, for part 3 please refer to http://news.chinatungsten.com/en/tungsten-information/79530-ti-10168)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Ⅲ

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 14:25

In part 2 we know that a tungsten carbide reamer usually consists of cutting edges with a slight undercut below each, a cylindrical body partly as the shank, and mostly preferred clockwise spiral, and the shanks have also different types for respective purpose.And here we reveal the different effect of reaming and drilling in making hole size.

Difference of reaming and drilling in sizing

The geometry of a hole drilled in metal by a twist drill may not be accurate enough (close enough to a true cylinder of a certain precise diameter) and may not have the required smooth surface finish for certain engineering applications. Although modern twist drills can perform excellently in many cases—usually producing sufficiently accurate holes for most applications—sometimes the stringency of the requirements for the hole's geometry and finish necessitate two operations: a drilling to slightly undersize, followed by reaming with a tungsten carbide reamer. The planned difference between the drill diameter and the reamer diameter is called an allowance. (It allows for the removal of a certain small amount of material.) The allowance should be < 0.2 mm (.008 in) for soft materials and < 0.13 mm (.005 in) for hard materials. Larger allowances can damage the reamer. The drilled hole should not be enlarged by more than 5% of the drilled diameter. Drilling followed by reaming generally produces hole geometry and finish that is as close to theoretical perfection as possible. (The other methods of hole creation that approach nearest to perfection under certain conditions are boring , especially single-point boring] and internal cylindrical grinding.)

(To be continued. This article is divided into several parts and this is part 3, for part 2 please refer to http://news.chinatungsten.com/en/tungsten-information/79457-ti-10166; for part 4 please refer to http://news.chinatungsten.com/en/tungsten-information/79531-ti-10169)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Military Spheres

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 October 2015 13:46

With the highest densities weighting in at 1.7 times heavier than lead, tungsten is the best ideal material for military defense used in military. On the other hand, tungsten is non-toxic, so it is the related product for lead which was used in bullet and shot to reduce the environmental hazardous materials in the military field. As well owing to its great hardness and resistance to high temperature, tungsten alloy sphere has been applied in military defense increasingly today.

Tungsten alloy sphere can be also used as bullets or pellets in many military filed. These are the pellets from inside a shotgun shell. Lead shot and bullets have been banned in many areas because they poison the environment. The main substitute materials are steel, bismuth and tungsten. The main advantages of tungsten alloy ball which made as pellet are that it's very dense, and very hard. The density allows the pellets to fly long distances without slowing down, while the hardness allows the pellets to keep their shape while being accelerated by the powder charge, which increases the muzzle velocity.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Erosion Mechanism

- Details

- Category: Tungsten Information

- Published on Monday, 19 October 2015 16:45

Pulsed arc supplies the current in pulsed form, and there are two other arc types, such as DC (Direct Current) arc and AC (Alternating Current). It is a phenomenon of gas discharge, which current generated instant spark through some insulating medium (like air). The extent of erosion of tungsten copper electrode surface is related to the power of energy of pulsed arc. For tungsten copper, the main form of electrode erosion is the evaporation of materials.

The effect of pulsed arc is positively correlated with single and total amount of pulsed charge transfer, and the extent of erosion is directly related to single charge transfer when the total amount of charge transfer is fixed. Some experiments shows that when single charge transfer is 1.48C and the total amount of charge transfer is 518C the erosion can not be seen except some Cu evaporating spots. However, the surface of tungsten copper electrode has scaly cracks.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode and Other Materials Comparison IX

- Details

- Category: Tungsten Information

- Published on Monday, 19 October 2015 16:44

In Micro- EDM, the electrode will increase the energy of spark in unit area, which increase the wastage and decrease the precision of machining. If we change the parameters to reduce the discharge energy unit area, the processing will be longer and efficiency will decrease. Therefore, the choice of electrode materials is also important for Micro-EDM, the common electrode materials are tungsten (W), tungsten carbide (WC) and tungsten copper (W-Cu), etc. Drilling and milling in Micro-EDM often uses tungsten (W) or tungsten carbide (WC) rod or tube as the electrode of tools.

In conclusion, we should choose different materials of electrode according to different process parameters or different work-pieces. Therefore, learn some methods, materials, shape, customer requirements and cost performance before we choose electrode is significant to the quality of products. In addition, tungsten copper and other new materials will promote the development of EDM (Electrical discharge machining).

-The End-

More information about tungsten copper electrode and other materials comparison, click here:

http://news.chinatungsten.com/en/tungsten-information/79286-ti-10093

http://news.chinatungsten.com/en/tungsten-information/79316-ti-10129

http://news.chinatungsten.com/en/tungsten-information/79338-ti-10130

http://news.chinatungsten.com/en/tungsten-information/79339-ti-10131

http://news.chinatungsten.com/en/tungsten-information/79397-ti-10135

http://news.chinatungsten.com/en/tungsten-information/79398-ti-10136

http://news.chinatungsten.com/en/tungsten-information/79428-ti-10137

http://news.chinatungsten.com/en/tungsten-information/79430-ti-10140

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Shot

- Details

- Category: Tungsten Information

- Published on Monday, 19 October 2015 15:10

Tungsten alloy shot is used as the shot for shotgun hunting shells. The pellets spread upon leaving the barrel, and the power of the burning charge is divided among the pellets, which means that the energy of any one ball of shot is fairly low. In a hunting context, the product makes shotguns useful primarily for hunting birds and other small games.

Properties of Tungsten Alloy Shot:

High density, great hardness and resistance to high temperature make tungsten to be one of the most sought -after material for shotgun pellets in hunting history. Density of tungsten alloy shot is about 18g/cm3, which is comparable only to gold, platinum, or bismuth. To understand how the density factors of tungsten heavy alloy into performance, let us look at two spheres about the same size of tungsten alloy shot, a golf ball and a ping -pong ball. The golf ball is far denser and will fly farther and hit harder. Now shrink the ball size down to two single points, we can get clear comparison graphic. Tungsten alloy will fly farther, hit harder and penetrate deeper. Another unique property of tungsten alloy is that it is non-toxic and environmentally friendly. Therefore, it is safe for people to handle and work.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com