Failure Modes of Tungsten Carbide Cutters Ⅲ

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 October 2015 15:13

In part 2 we know that corrosion/ leaching wear is one of the most common failure modes of tungsten carbide cutters, while involving only the metallic binder matrix instead of tungsten carbide particles inside, and therefore a moderate or highly corrosive working environment shall be carefully avoided for carbide cutters. In this part we will talk about chipping/fracturing wear as another failure mode.

3. Chipping/Fracturing Wear

Except at relatively high temperatures, tungsten carbides cutters undergo little plastic deformation prior to failing by brittle fracture. Carbide grades vary widely in tensile strength and toughness and premature failure by chipping or fracture occurs whenever the carbide component lacks the toughness to withstand service conditions that include mechanical shock or impact. Sharp, unprotected edges of tungsten carbide cutters are particularly vulnerable to chipping. Cracks generally initiate in areas associated with high stress concentrations and, once moving, propagate rapidly through the carbide component to produce failure by fracture. Carbides have relatively high compressive strengths, however, and any change in either part geometry or operating conditions that converts tensile stresses to compressive stresses reduces the probability of failure by fracture. Design considerations that reduce the risk of failure by chipping or fracture include the use of protective edge chamfers and radii, avoiding sharp inside edges and other stress-inducing features, increasing the wall thickness of tubes and wear sleeves, and improving surface finishes. In certain instances chipping or fracture occurs as a result of the increased stresses associated with a badly worn carbide component. When this is the case, wear is the primary cause of failure even though catastrophic failure by fracture or breakage may mask it.

(To be continued. This article is divided into 9 parts and this is part 3, for part 2 please refer tohttp://news.chinatungsten.com/en/tungsten-information/79330-ti-10138)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide CuttersⅡ

- Details

- Category: Tungsten Information

- Published on Tuesday, 13 October 2015 15:09

In part 1 we know that tungsten carbide cutters fail in many different modes such as abrasive/erosion wear mode, which means a form of mechanical attack at the working surface of the carbide component and meanwhile not resulting in a total breakdown or stoppage of the operation dependent on the failing component. In this part we will talk about corrosion/leaching wear which is one of the most common failure modes of tungsten carbide cutters.

2. Corrosion/Leaching Wear

Corrosion wear is the result of a chemical or electrochemical reaction between tungsten carbide cutter surfaces and the environment. These reactions generally involve the metallic binder matrix (cobalt or nickel) rather than the tungsten carbide grains and, with the loss of the binder metal at exposed surfaces, the mechanical bond holding the carbide grains in place is also lost. Acidic liquids are particularly corrosive. A cobalt binder is far more susceptible to chemical attack or “leaching” than nickel and should be avoided in moderate to highly corrosive environments. Corrosion rate data for specific situations are seldom available and are typically determined empirically.

(To be continued. This article is divided into 9 parts and this is part 2, for part 1 please refer to http://news.chinatungsten.com/en/tungsten-information/79302-ti-10133; for part 3 please refer tohttp://news.chinatungsten.com/en/tungsten-information/79331-ti-10139)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode and Other Materials Comparison II

- Details

- Category: Tungsten Information

- Published on Monday, 12 October 2015 17:45

With the development of EDM, the material of electrode and the related manufacture makes a great progress. At present, there are so much electrode materials, such as graphite, tungsten (W), copper (Cu) and some other metal or non-metal elementary substances. In addition, steel, cast steel, Cu-based and W-based composite materials or diamond can be also used as EDM electrode.

1. Graphite

As for the aspect of chemical, graphite is an allotrope of carbon element, which covalently bound covalent molecular bonds. Its has high boiling point and melting point, the melting point up to 3652 ℃, the boiling point of 4827 ℃, insoluble in water. And it also has excellent electrical and thermal conductivity, chemical stability and workability so that it is widely used as EDM electrodes. In addition, graphite also has different kinds, which can be specifically divided by graphite particle density, the size and mechanical and electrical properties.

More information about tungsten copper electrode and other materials comparison, click here:

http://news.chinatungsten.com/en/tungsten-information/79286-ti-10093

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Failure Modes of Tungsten Carbide CuttersⅠ

- Details

- Category: Tungsten Information

- Published on Monday, 12 October 2015 11:23

Tungsten carbide cutters fail in a number of different ways. Unfortunately, there is no “one best” grade of carbide for all applications and replacing one grade with another may decrease the probability of one type of failure from occurring, but generally increases the odds that a different one will occur. Carbide grades are normally selected so that the useful life of the cutters and the mode of failure are fairly predictable. In this way unscheduled or disruptive outages of the assemblies which include the carbide component are avoided and the scheduled replacement of parts prior to failure is an option. A brief description of each of the common modes of failure follows.

1. Abrasive /Erosion Wear

Abrasive or erosion wear represents a form of mechanical attack at the working surface of the carbide component. It is the progressive loss of material at the carbide surface due to a high velocity stream of liquid or gas containing solid particles directed into or flowing across the surface of the carbide cutters. It may also result from the sliding or rubbing of a mating component or work material over the carbide cutter surface. The rate of wear depends in part on the force or pressure with which the contact medium impinges on the carbide cutter surface. The progressive wear caused by abrasion or erosion is a preferred mode of failure since it does not result in a total breakdown or stoppage of the operation dependent on the failing component.

(To be continued. This article is divided into 9 parts and this is part 1.)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

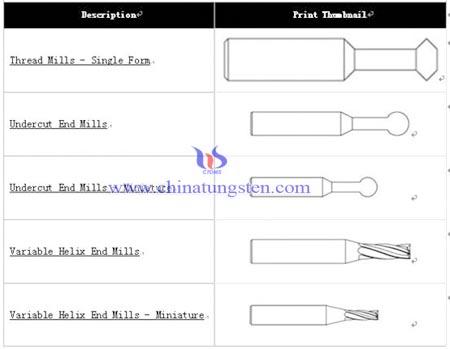

Types of Tungsten Carbide End Mills/Drills and Diagrams Ⅺ

- Details

- Category: Tungsten Information

- Published on Monday, 12 October 2015 11:20

In part 10, we know about Tapered Corner Radius End Mills, Tapered Corner Radius End Mills-Miniature, etc., and here in this part we will go on showing more diagrams of tungsten carbide end mills and drills.

Here we show more types of tungsten carbide end mills/drills, such as Thread Mills-Single Form, Undercut End Mills, etc., each type has different shape and application according to it's own work piece. From the below diagrams with the brief names we can have a direct knowledge on the basic figures and their respective function differentiation.

(The End. This article is divided into 11 parts and this is part 11, for part 10 please refer to:http://news.chinatungsten.com/en/tungsten-information/79274-ti-10127)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

High Density Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 12 October 2015 10:33

Tungsten powder now is more and more popular for its high density for many fields as a safe, economical alternative to lead powder.

Its density is in 99% pure high density similar to that of lead powder but with better properties especially its environmental-friendly. Tungsten powder is over 30% heavier than the highest density lead powder and due to the powdery textures ability for compression, can add more weight in less volume. Tungsten powder qualities are fabricated by hydrogen reduction and are available in average particle sizes from 0.1 (100nm) to 100µm, which offers the possibility to produce that of any desired average particle size within various limits only by changes in reduction conditions.

The purity of the tungsten powder is of particular importance in all applications, typical upper limits of foreign element concentrations in µg/g are:

Co, Cu, Mg, Mn, Pb ≤ 2

Al, Fe, Ni, Si, Ca, Cr, Sn ≤10

Mo ≤ 20

The crucial physical properties are average particle size, particle size distribution, apparent, tap and compact or green density, specific surface area, degree of agglomeration and morphology. They are to a certain extent related to each other and can be influenced between limits by the oxide properties and the reduction conditions. Extremely coarse powder gained by screening to separate any finer particles has excellent flow characteristics and is used in plasma spraying.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Darts QuotationsⅡ

- Details

- Category: Tungsten Information

- Published on Saturday, 10 October 2015 17:30

Some prize moments of genius from tungsten darts' most excitable commentator - Sid Waddell.

There are some interesting tungsten darts quotations:

"It's like Dracula getting out of his grave and asking for a few chips with his steak."

"That Lad could through 180 standing one legged in a hammock."

"This game of darts is twisting like a rattlesnake with a hernia!"

"It's just like taking a sausage from a boy in a wheelchair."

"That was like throwing three pickled onions into a thimble!"

"He's about as predictable as a Wasp on speed."

"Look at the man go, it's like trying to stop a water buffalo with a pea-shooter!"

"The atmosphere is so tense, if Elvis walked in, with a portion of chips....... you could hear the vinegar sizzle on them"

"Big Cliff Lazarenko's idea of exercise is sitting in a room with the windows open taking the lid off something cool and fizzy."

"Look at him as he takes his stance, like he has been sculptured, whereas Bobby George, with his bad back, looks like the Hunchback of Notre Dame."

"He's playing like Robin Hood in the Nottingham super league."

"They've got Shakespeare on Radio 2 but you can't beat this for drama."

"It's like trying to pin down a kangaroo on a trampoline."

"Well as giraffes say, you don't get no leaves unless you stick your neck out."

"His eyes are bulging like the belly of a hungry chaffinch."

"That's like giving Dracula the keys to the blood bank."

"As they say at the DHSS, we're getting the full benefit here."

"He is as slick as minestrone soup."

"There hasn't been this much excitement since the Romans fed the Christians to the Lions."

"Phil Taylor's got the consistency of a planet ... and he's in a darts orbit!"

"The atmosphere is a cross between the Munich Beer Festival and the Coliseum when the Christians were on the menu."

"Jockey Wilson, he comes from the valleys and he's chuffing like a choo-choo train!"

"He's planting those arrows with the accuracy of a couple of inter-continental ballistic missiles."

"Steve Beaton, he's not Adonis, he's the donis"

"The players are under so much duress, it's like duressic park out there!"

"He's like D'Artagnan at the scissor factory."

"This lad has more checkouts than Tescos."

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode and Other materials Comparison

- Details

- Category: Tungsten Information

- Published on Saturday, 10 October 2015 16:30

The using of electrode material has a huge effect on electrical discharge machining (EDM), such as the wastage of tool, MRR (Material Removal Rate), the surface quality of work-piece and so on. Therefore, the choice of electrode material should not be ignored in EDM and it depends on the situation.

First of all, the electrode should have high melting point, good conductivity, low coefficient of expansion and some excellent mechanical properties so that it can be thermal resistance, not easy to deformation and has low wastage in EDM. Theoretically, the micro crystal structure of electrode is beneficial for decreasing the wastage of electrode and properly reduce the size of grain will be better. In addition, the material of electrode should pledge stability, good quality of surface, reasonable price and easily for machining to EDM.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Typical Properties of Commonly Used Copper-tungsten Electrode Composition

- Details

- Category: Tungsten Information

- Published on Saturday, 10 October 2015 16:28

Typical properties of commonly used copper-tungsten electrode composition

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

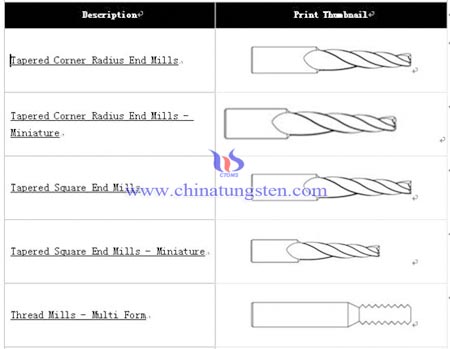

Types of Tungsten Carbide End Mills/Drills and Diagrams Ⅹ

- Details

- Category: Tungsten Information

- Published on Saturday, 10 October 2015 14:22

In part 9, we know about such as Square End Mills-Long Reach, Square End Mills-Miniature, etc. And here in this part we will go on showing more diagrams of tungsten carbide end mills.

Here we show more types of tungsten carbide end mills/Drills, such as Tapered Corner Radius End Mills, Tapered Corner Radius End Mills-Miniature,Tapered Square End Mill etc., each type has different shape and application according to it's own work piece. From the below diagrams with the brief names we can have a direct knowledge on the basic figures and their respective functions.

(To be continued. This article is divided into 11 parts and this is part 10, for part 9 please refer to:http://news.chinatungsten.com/en/tungsten-information/79273-ti-10126)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com